Construction machinery operates in tough environments, where heat can build up quickly and damage sensitive components like printed circuit boards (PCBs). Effective thermal management is critical to ensure reliability and performance. So, how do you protect PCBs in construction equipment from overheating? The answer lies in smart PCB thermal design, innovative cooling techniques, and strategic material choices tailored for harsh conditions.

In this blog, we’ll explore practical thermal management solutions for construction machinery PCBs. From heat dissipation methods to design tips, we’ll cover everything you need to keep your equipment running smoothly, even under extreme heat. Let’s dive into the details of managing construction equipment heat and ensuring your PCBs stay robust.

Why Thermal Management Matters for Construction Machinery PCBs

Construction machinery, like excavators, bulldozers, and cranes, often works in high-stress environments with dust, vibration, and temperature swings. The electronic control systems in these machines rely on PCBs to function, but excess heat can cause failures, reduce lifespan, and lead to costly downtime. Studies show that for every 10°C rise in operating temperature, the failure rate of electronic components can double. That’s why managing heat is not just a design choice—it’s a necessity.

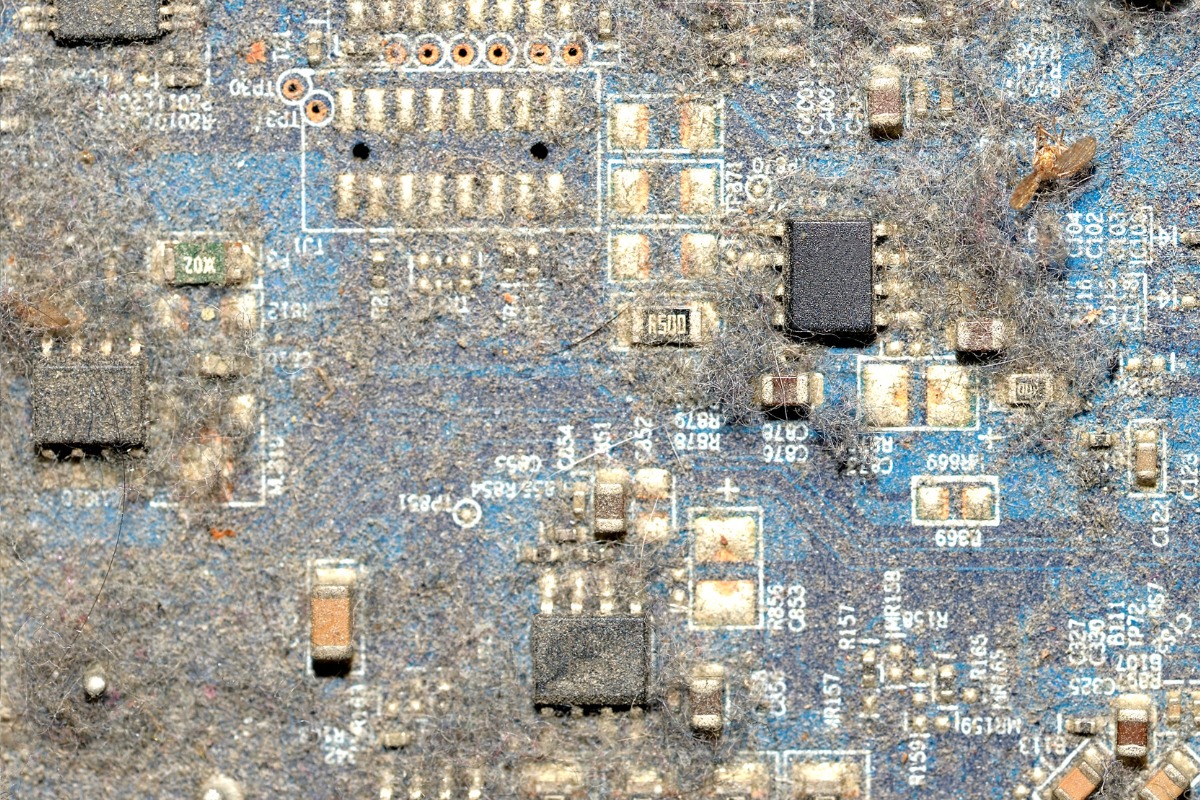

PCBs in construction equipment face unique challenges. They’re exposed to engine heat, direct sunlight, and limited airflow in enclosed spaces. Without proper PCB thermal design, components can overheat, leading to issues like signal delays or complete system shutdowns. By focusing on effective cooling techniques, you can boost reliability and keep operations running without interruptions.

Key Challenges of Heat in Construction Equipment

Before diving into solutions, let’s break down the specific heat-related challenges for PCBs in construction equipment:

- High Ambient Temperatures: Machines often operate in outdoor settings where temperatures can exceed 40°C (104°F), especially in desert or tropical regions.

- Enclosed Spaces: Many PCBs are housed in sealed compartments to protect against dust and moisture, but this traps heat and restricts airflow.

- High Power Components: Modern machinery uses power-intensive electronics, generating significant heat during operation.

- Vibration and Shock: Constant movement can loosen heat dissipation components like heat sinks if not secured properly.

Addressing these challenges requires a combination of smart design and proven PCB cooling techniques. Let’s explore the best strategies to manage construction equipment heat effectively.

Effective PCB Thermal Design Strategies for Construction Machinery

Good thermal management starts at the design stage. By planning ahead, you can minimize heat buildup and ensure your PCBs withstand the toughest conditions. Here are some key strategies for PCB thermal design:

1. Optimize Component Placement

Place heat-generating components, like power transistors or microcontrollers, away from each other to prevent localized hot spots. Spread them across the board to distribute heat evenly. Also, position sensitive components away from heat sources to protect them from thermal stress. For example, if a voltage regulator operates at 85°C, placing it near a temperature-sensitive sensor could cause inaccurate readings or failure.

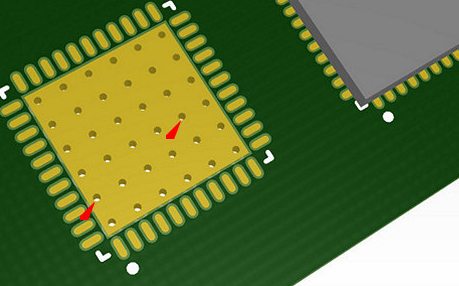

2. Use Thermal Vias for Heat Transfer

Thermal vias are small holes filled with conductive material, usually copper, that transfer heat from one layer of the PCB to another. By connecting hot components to a ground plane or heat sink layer, thermal vias can reduce temperatures by up to 20%. In construction machinery PCBs, where space is often limited, adding an array of thermal vias under high-power chips can make a big difference.

3. Select Heat-Resistant Materials

The choice of PCB substrate material plays a huge role in thermal performance. Standard FR-4 materials work for low-heat applications but may not hold up in extreme conditions. For construction machinery, consider high-Tg (glass transition temperature) FR-4 or metal-core PCBs (MCPCBs). MCPCBs, with their aluminum or copper base, can dissipate heat up to 10 times better than standard materials, making them ideal for high-power applications.

PCB Cooling Techniques for Construction Equipment Heat

Beyond design, active and passive cooling techniques are essential to manage heat in real-world conditions. Here are some proven methods to keep your PCBs cool:

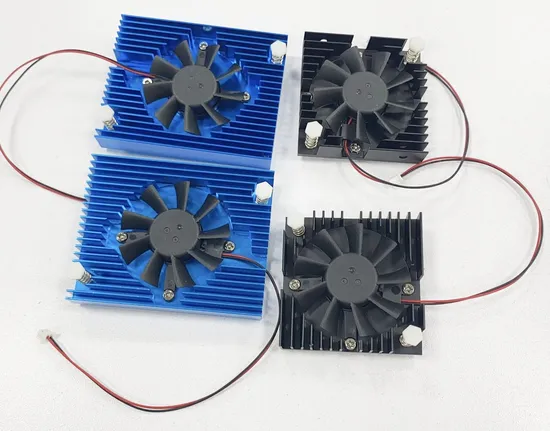

1. Heat Sinks for Passive Cooling

Heat sinks are metal structures attached to hot components to absorb and dissipate heat into the surrounding air. For construction machinery, use rugged heat sinks made of aluminum or copper with fins to increase surface area. Ensure they’re securely mounted to withstand vibrations. A well-designed heat sink can reduce component temperatures by 15-30°C, depending on airflow and ambient conditions.

2. Forced Air Cooling with Fans

In enclosed compartments, natural airflow may not be enough. Small, durable fans can force air over the PCB to remove heat. Choose industrial-grade fans rated for high temperatures and dust resistance. For example, a fan moving air at 20 cubic feet per minute (CFM) can lower PCB temperatures significantly, even in a confined space. Just ensure proper sealing to prevent dust ingress.

3. Thermal Pads and Compounds

Thermal interface materials (TIMs), like thermal pads or compounds, improve heat transfer between components and heat sinks. They fill microscopic gaps, ensuring efficient conduction. For instance, a thermal compound with a conductivity of 4 W/m·K can reduce thermal resistance by 50% compared to direct contact. In rugged environments, opt for non-silicone TIMs to avoid degradation over time.

Advanced Thermal Management Solutions

For high-performance construction machinery, basic cooling may not cut it. Here are some advanced solutions to tackle extreme heat:

1. Metal Core PCBs for Superior Heat Dissipation

As mentioned earlier, metal core PCBs use a metal base layer to spread heat across the board. They’re especially useful for power electronics in machinery like hydraulic controllers. Tests show that MCPCBs can handle heat fluxes up to 100 W/cm2, far exceeding standard materials. They also provide mechanical strength, which is a bonus in vibrating environments.

2. Embedded Heat Pipes

Heat pipes are sealed tubes filled with a liquid that evaporates and condenses to transfer heat efficiently. Embedding heat pipes in or near a PCB can move heat away from critical areas to a cooler spot or external heat sink. While more complex to implement, they can reduce hotspot temperatures by up to 40%, making them ideal for compact, high-power systems.

3. Conformal Coatings for Thermal and Environmental Protection

Conformal coatings protect PCBs from dust and moisture, but some also offer thermal benefits. Certain coatings improve heat dissipation by reducing thermal resistance at the surface. Look for coatings with high thermal conductivity to enhance performance without compromising protection.

Testing and Validation for Thermal Performance

Designing for heat is only half the battle. You must test and validate your PCB thermal design to ensure it works in real-world conditions. Use thermal simulation software during the design phase to predict hot spots and airflow patterns. Tools can estimate temperature rises with accuracy within 5-10% of actual results.

After prototyping, conduct physical testing in conditions mimicking the construction site. Place temperature sensors on critical components and run the system at full load for extended periods. For example, if a processor on your PCB reaches 90°C under load in a 40°C environment, you may need additional cooling or design tweaks to bring it down to a safe 70-80°C.

Practical Tips for Implementing Thermal Management

Here are some quick, actionable tips to improve thermal management for construction machinery PCBs:

- Use copper pours on PCB layers to act as mini heat spreaders, increasing thermal mass.

- Design enclosures with ventilation slots or grilles, ensuring they’re dust-proof with filters.

- Monitor component datasheets for maximum operating temperatures (often 85-125°C) and design below these limits.

- Consider redundancy for critical systems, so if one PCB overheats, a backup can take over temporarily.

Conclusion: Building Robust PCBs with Smart Thermal Management

Thermal management is a cornerstone of reliable PCB design for construction machinery. By focusing on smart PCB thermal design, using effective PCB cooling techniques, and selecting the right materials, you can protect your equipment from the dangers of construction equipment heat. Whether it’s optimizing component layout, adding thermal vias, or using advanced solutions like metal core PCBs, every step counts in ensuring durability and performance.

At ALLPCB, we understand the challenges of designing for harsh environments. Our expertise and resources can help you create robust PCBs with cutting-edge thermal management solutions. Start integrating these strategies into your next project to keep your machinery running strong, no matter the conditions.

ALLPCB

ALLPCB