Hand soldering is a critical skill in electronics, whether you're a hobbyist working on a small project or a professional assembling complex circuit boards. One tool that can significantly boost your soldering game is a set of helping hands. But why are helping hands so important? Simply put, they improve efficiency and precision by holding components steady, freeing up your hands to focus on soldering. In this comprehensive guide, we'll dive into the role of helping hands, how they fit into an optimal soldering station setup, and tips for improving soldering precision. Let's explore how the best helping hands for soldering can transform your workflow.

Why Helping Hands Are Essential for Hand Soldering

Soldering requires a steady hand and complete focus. You're often juggling a soldering iron, solder wire, and tiny components that need to stay perfectly aligned. Without assistance, it's easy to make mistakes, like misaligning parts or creating cold solder joints. Helping hands act as an extra set of hands, securely holding components in place so you can concentrate on the task at hand.

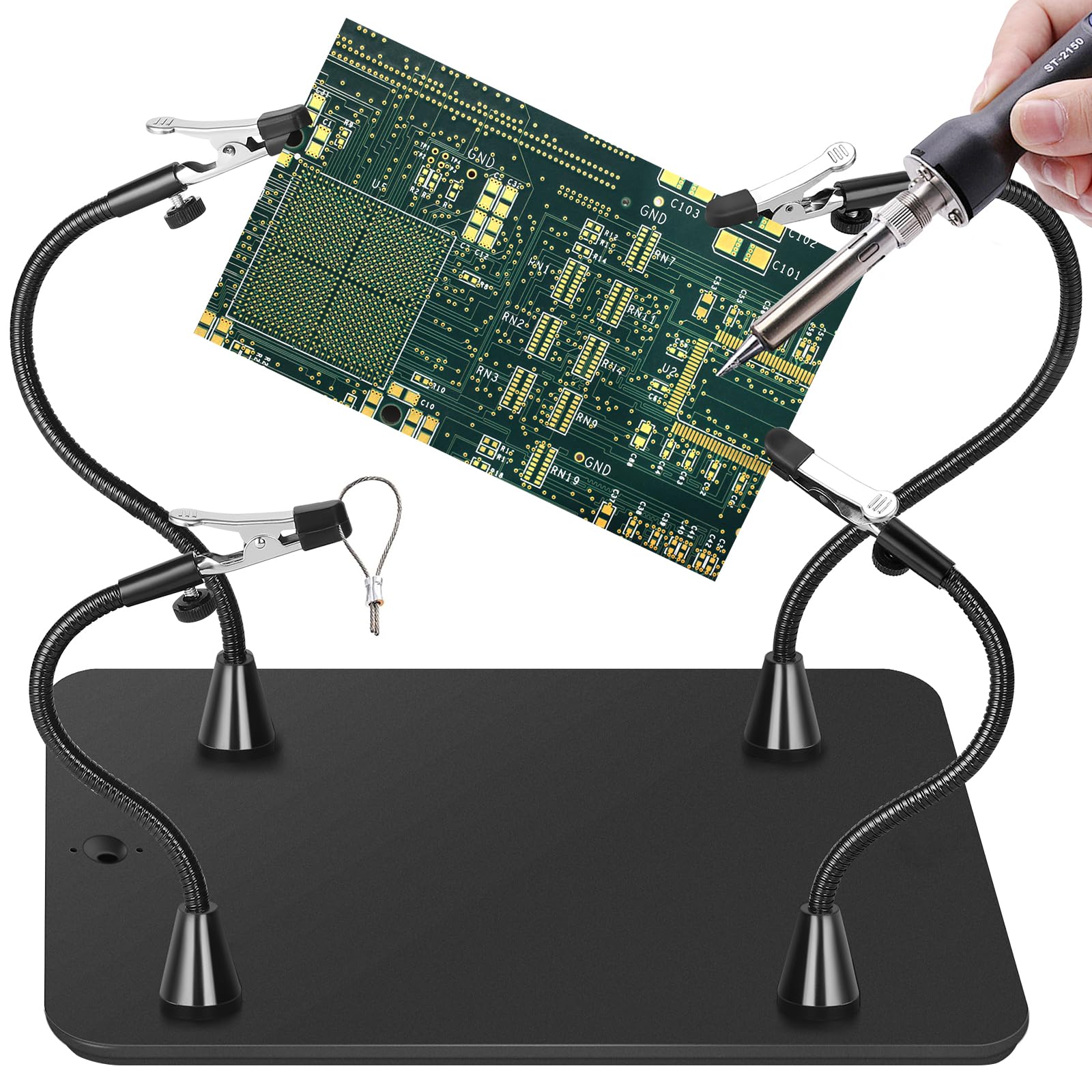

These tools typically consist of a weighted base with adjustable arms equipped with alligator clips. Some advanced models even include magnifying glasses or LED lights for better visibility. By stabilizing your workpiece, helping hands reduce errors, save time, and ensure cleaner, more reliable connections. For anyone serious about electronics, investing in the best helping hands for soldering is a game-changer.

Key Benefits of Using Helping Hands in Soldering

Helping hands aren't just a convenience—they offer tangible benefits that directly impact the quality of your work. Here are some of the top advantages:

1. Enhanced Precision

Soldering tiny components, like surface-mount devices (SMDs) with pin spacings as small as 0.5 mm, demands pinpoint accuracy. Helping hands keep components firmly in place, preventing movement during soldering. This stability is crucial for avoiding issues like bridged pins or uneven joints, ultimately improving soldering precision.

2. Increased Efficiency

Without helping hands, you might spend extra time trying to hold components with tweezers or tape while soldering. Helping hands streamline the process by holding everything securely, allowing you to work faster. For instance, assembling a board with 20 through-hole components can take significantly less time when you don't have to reposition parts constantly.

3. Reduced Risk of Damage

Manually holding components can lead to accidental slips, damaging delicate parts or burning your fingers with a 300°C soldering iron. Helping hands minimize these risks by providing a stable, hands-free solution, protecting both you and your project.

4. Versatility for Various Projects

Whether you're soldering wires, connectors, or intricate circuit boards, helping hands adapt to different tasks. Adjustable arms and clips can accommodate a wide range of component sizes, making them a versatile addition to any soldering station setup.

Choosing the Best Helping Hands for Soldering

Not all helping hands are created equal. With so many options available, selecting the right one for your needs can make a big difference in your soldering experience. Here are key factors to consider when looking for the best helping hands for soldering:

1. Stability and Build Quality

A sturdy base is essential to prevent tipping during use. Look for a weighted or cast-iron base that keeps the tool steady, even when holding larger components. High-quality arms made of durable materials like steel ensure long-term reliability.

2. Adjustable Arms and Clips

Flexibility is key. Opt for helping hands with multiple adjustable arms—models with two to six arms are common. The clips should have a strong grip but be gentle enough not to damage delicate components. Some clips come with rubber coatings to prevent scratching.

3. Additional Features

Some models offer extras like built-in magnifying glasses (with magnification levels of 2x to 5x) or LED lights for better visibility. These features are especially useful when working on small components or in low-light conditions.

4. Size and Portability

Consider the size of the helping hands relative to your workspace. Compact models are ideal for small desks, while larger ones with more arms suit complex projects. If you work in multiple locations, a lightweight, portable option is a plus.

Integrating Helping Hands into Your Soldering Station Setup

A well-organized soldering station setup is vital for efficient and precise work. Helping hands play a central role, but they work best when paired with other essential tools. Here's how to create an effective soldering station setup with helping hands as a key component:

1. Core Soldering Equipment

Start with a reliable soldering iron or station with adjustable temperature control (typically ranging from 200°C to 450°C). Pair it with quality solder wire, such as 60/40 tin-lead or lead-free options with a diameter of 0.8 mm to 1.0 mm for general use. A soldering tip cleaner, like a brass wire sponge, is also essential to maintain clean tips for better heat transfer.

2. Workspace Organization

Set up your helping hands on a stable, heat-resistant surface, such as a silicone mat. Position it near the center of your workspace for easy access. Keep other tools, like tweezers and wire cutters, within arm's reach to minimize movement during soldering.

3. Lighting and Magnification

Good visibility is non-negotiable. If your helping hands don't include built-in lights or magnification, invest in a separate desk lamp with adjustable brightness and a magnifying glass. Proper lighting reduces eye strain and helps spot tiny defects in solder joints.

4. Safety Measures

Always prioritize safety in your soldering station setup. Use a soldering iron holder to prevent accidental burns, and work in a well-ventilated area or with a fume extractor to avoid inhaling harmful solder fumes. Keep a small fire extinguisher nearby for emergencies.

By integrating helping hands into this setup, you create a workspace that supports both efficiency and precision, allowing you to tackle projects of varying complexity with confidence.

Tips for Improving Soldering Precision with Helping Hands

Helping hands are a fantastic tool, but maximizing their benefits requires proper technique. Here are actionable tips for improving soldering precision using helping hands:

1. Position Components Strategically

Before soldering, use the helping hands to position components at the correct angle. For example, when soldering a resistor to a board, align it so the leads are flush with the pads. Secure the board and component with the clips to prevent any movement during the process.

2. Use the Right Amount of Solder

Over-soldering can create messy joints or bridges, while under-soldering leads to weak connections. Apply just enough solder to form a small, shiny cone around the joint—typically 1-2 mm of solder wire per connection. Helping hands keep everything steady, making it easier to control the solder flow.

3. Maintain a Clean Soldering Tip

A dirty tip reduces heat transfer and affects precision. Clean your soldering iron tip frequently using a damp sponge or brass wire cleaner. With helping hands holding your workpiece, you can focus on maintaining your tools without worrying about components shifting.

4. Work at the Correct Temperature

Using the right temperature prevents damage to components and ensures smooth solder flow. For most through-hole components, a temperature of 300°C works well, while SMD components may require 250°C to 280°C. Helping hands allow you to focus on adjusting settings without juggling parts.

5. Inspect Joints Carefully

After soldering, use the magnification feature (if available) on your helping hands to inspect joints for defects like cracks or insufficient solder. Catching issues early prevents rework and ensures reliable connections.

Common Mistakes to Avoid When Using Helping Hands

While helping hands are incredibly useful, improper use can lead to frustration or poor results. Here are some common pitfalls to watch out for:

1. Over-Tightening Clips

Clips that are too tight can damage fragile components or scratch surfaces. Adjust the grip just enough to hold the item securely without applying excessive pressure.

2. Poor Positioning

If the helping hands are placed too far from your soldering area, you may struggle to reach components comfortably. Position the tool close to your primary workspace to maintain a natural soldering posture.

3. Ignoring Stability

Using a lightweight or unstable helping hands tool can cause it to tip over during use, disrupting your work. Always choose a model with a solid base, and double-check its stability before starting.

How Helping Hands Support Different Soldering Projects

Helping hands are versatile enough to assist with a wide range of soldering tasks. Here are a few examples of how they can be used in different scenarios:

- Through-Hole Soldering: When soldering components like resistors or capacitors with leads, helping hands hold the component in place while you apply solder to the underside of the board.

- Surface-Mount Soldering: For tiny SMD components, helping hands stabilize the board, allowing you to use tweezers and a fine-tip soldering iron with precision.

- Wire Soldering: When joining wires or soldering connectors, helping hands can hold the wires together, ensuring a clean and secure connection.

No matter the project, helping hands adapt to your needs, making them an indispensable tool for any electronics enthusiast or professional.

Conclusion: Elevate Your Soldering with Helping Hands

In the world of hand soldering, efficiency and precision are everything. Helping hands provide the stability and support needed to achieve clean, reliable connections while saving time and reducing frustration. By choosing the best helping hands for soldering and integrating them into a well-thought-out soldering station setup, you can take your skills to the next level. Remember to follow best practices, like positioning components carefully and maintaining your tools, to maximize the benefits of this essential tool.

Whether you're a beginner tackling your first project or a seasoned pro handling complex assemblies, helping hands are a small investment with a big impact. Start improving soldering precision today by adding this versatile tool to your workspace, and watch as your projects become smoother and more professional.

ALLPCB

ALLPCB