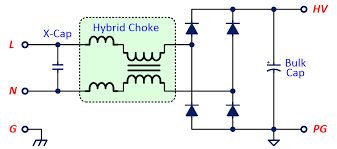

EMI suppression can be achieved through various methods, including filter combinations, transformer winding arrangements, and PCB layout. This article introduces a hybrid magnetic component that combines a common-mode choke with a differential-mode inductor, known as a hybrid common-mode choke. This component retains the high impedance of a standard common-mode choke while leveraging its significant leakage inductance to function as a differential-mode inductor. This approach reduces the filter's size and cost and offers engineers a quick solution for conducted EMI issues.

Principles and Function of Hybrid Common-Mode Chokes

In a conventional single-stage EMI filter circuit, common-mode noise filters (using components like LCM, CY1, and CY2) and differential-mode noise filters (using LDM, CX1, and CX2) form LC filters to attenuate their respective noise types. Common-mode chokes are typically made from high-permeability manganese-zinc (Mn-Zn) ferrite, offering inductance values from 1 mH to 50 mH. Due to their winding polarity, the magnetic flux generated by the load current in each of the two windings cancels out within the core, preventing core saturation. Common core shapes include toroidal, UU, ET, and UT types. To achieve sufficient common-mode inductance, the coupling between the two windings must be maximized. This is why toroidal cores or single-piece ET and UT cores are often used, despite their higher manufacturing costs.

Based on the operating principle and equivalent circuit of a common-mode choke, a dual-winding choke inherently has some leakage inductance caused by leakage flux, even with good coupling. This leakage inductance is effectively in series with the circuit, making it functionally identical to a separate differential-mode inductor. Therefore, the leakage inductance of a common-mode choke can be utilized for differential-mode filtering. However, in conventional common-mode chokes, the mechanical design results in a very small leakage inductance, typically from a few microhenries (µH) to around 100 µH. Increasing leakage inductance would require more winding turns, which necessitates a smaller wire diameter and reduces the current-carrying capacity. The alternative is to use a larger core, which increases the filter's size and cost. In many applications requiring a high common-mode inductance, the goal is often to achieve a larger leakage inductance for differential-mode filtering—a point that is not always well understood by engineers.

A special core structure and winding method are used to intentionally increase the leakage inductance of a common-mode choke, creating what is known as a hybrid common-mode choke (or integrated common-mode choke). This design retains sufficient common-mode inductance for filtering common-mode noise, while its leakage inductance provides a differential-mode inductance of up to several hundred microhenries (µH). When paired with an appropriate X-capacitor, this component can effectively filter differential-mode signals in the low-to-mid frequency range (150 kHz to 3 MHz). Experimental results confirm that hybrid common-mode chokes offer excellent filtering performance, with the added benefits of low cost and a compact size.

ALLPCB

ALLPCB