If you're new to electronics and wondering how to replace components on a printed circuit board (PCB), a rework station is your go-to tool. In this guide, we’ll walk you through the basics of using a PCB rework station for component replacement. Whether you're fixing a faulty part or upgrading a board, this simple guide covers everything you need to know about PCB rework for beginners, including soldering tips and hot air techniques.

Let’s dive into the detailed steps, tools, and techniques to help you master rework station basics and confidently tackle component replacement. From understanding the equipment to practical tips for success, this blog is your starting point for building skills in PCB repair and modification.

What Is a PCB Rework Station and Why Do You Need One?

A PCB rework station is a specialized tool designed to help you repair or modify printed circuit boards by removing and replacing components. Unlike a regular soldering iron, a rework station often combines multiple functions, such as hot air for surface-mount device (SMD) components and precise temperature control for delicate work. For beginners, having a rework station is essential because it makes tasks like desoldering and soldering much easier and safer.

Rework stations are especially useful for:

- Fixing manufacturing defects by replacing faulty components.

- Upgrading or customizing a PCB with new parts.

- Salvaging components from old boards for reuse.

- Correcting soldering mistakes, such as excess solder or misplaced parts.

For anyone starting with electronics, learning to use a rework station opens up a world of possibilities in repair and design. It’s a must-have tool for tackling component replacement with precision.

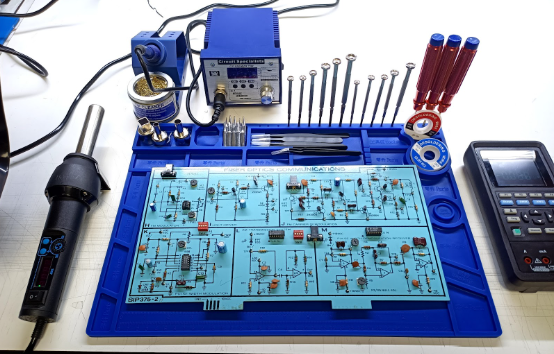

Understanding Rework Station Basics: Key Components

Before diving into a soldering tutorial for beginners, let’s break down the main parts of a rework station. Most beginner-friendly rework stations come with two primary tools: a soldering iron and a hot air gun. Here’s what each does and why it matters.

1. Soldering Iron

The soldering iron is used for traditional through-hole components and some SMD parts. It applies heat directly to solder, allowing you to attach or remove components. Look for a rework station with adjustable temperature settings (typically between 200°C to 450°C) to avoid damaging sensitive parts.

2. Hot Air Gun

The hot air gun is the star of hot air rework for beginners. It blows heated air to melt solder on SMD components, making it easy to remove or place tiny parts without direct contact. Hot air guns usually have temperature ranges from 100°C to 500°C and adjustable airflow settings (often measured in liters per minute, like 20-120 L/min) to control heat distribution.

3. Control Unit

The control unit is the brain of the rework station. It lets you set and monitor temperatures for both the soldering iron and hot air gun. Some stations also include digital displays for precision, which is great for beginners learning to manage heat levels.

Types of PCB Rework: SMT vs. THT

When starting with PCB rework for beginners, it’s important to understand the two main types of components you’ll encounter: Surface Mount Technology (SMT) and Through-Hole Technology (THT). Each requires a slightly different approach for replacement.

Surface Mount Technology (SMT)

SMT components are small and sit flat on the PCB surface. They’re common in modern electronics due to their compact size. Hot air rework is the best method for SMT parts because it evenly heats multiple solder points at once. For example, a typical SMT resistor might have solder pads only 1-2 mm wide, requiring precise heat control to avoid damaging nearby components.

Through-Hole Technology (THT)

THT components have leads that go through holes in the PCB and are soldered on the other side. These are often larger, like capacitors or connectors. A soldering iron is usually enough for THT rework, though a desoldering pump or wick may be needed to remove old solder.

Understanding whether you’re working with SMT or THT components will guide your tool choice and technique during component replacement.

Essential Tools for PCB Rework Beyond the Station

While a rework station is the core of your setup, a few additional tools will make component replacement smoother. Here’s what beginners should have on hand:

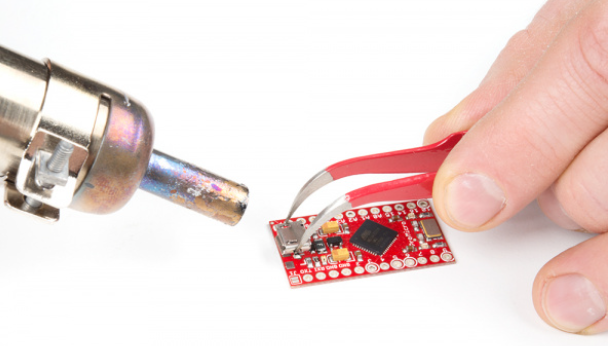

- Tweezers: For handling small SMT components. Anti-static tweezers are best to prevent damage from static electricity.

- Desoldering Wick: A braided copper wire that absorbs excess solder when heated. Useful for cleaning up pads before placing new components.

- Flux: A chemical agent that helps solder flow and stick better. It’s essential for clean connections, especially with SMD parts.

- Solder Paste: Used with hot air rework for SMT components. It’s a mix of tiny solder particles and flux, applied to pads before heating.

- Heat-Resistant Mat: Protects your workspace from high temperatures (hot air can reach 500°C or more).

Having these tools ready will save time and prevent frustration during your first rework projects.

Step-by-Step Component Replacement Guide for Beginners

Now that you’re familiar with the tools and basics, let’s walk through a practical component replacement guide. This process focuses on SMT components using hot air, as they’re common in modern PCBs and trickier for beginners to handle.

Step 1: Prepare Your Workspace

Set up on a heat-resistant mat in a well-ventilated area. Hot air rework produces fumes from flux and solder, so safety is key. Wear safety glasses to protect your eyes from stray solder or hot air. Ensure your PCB is secured, either with a PCB holder or by placing it flat on the mat.

Step 2: Identify the Component to Replace

Locate the faulty or outdated component. If it’s an IC chip, note its orientation (look for a dot or notch indicating pin 1) so you can align the replacement correctly. Use a magnifying glass if needed—SMT parts can be as small as 1 mm across.

Step 3: Remove the Old Component with Hot Air

Set your hot air gun to a temperature of about 300°C-350°C and a low airflow setting (around 20-30 L/min) to start. Hold the nozzle 2-3 cm above the component and move it in a circular motion to evenly heat the solder. After 10-20 seconds, the solder should melt (it will look shiny). Use tweezers to gently lift the component off. Avoid keeping the heat in one spot for too long to prevent burning the PCB—most boards can only withstand temperatures up to 260°C for short periods.

Step 4: Clean the Pads

Once the component is removed, there will likely be leftover solder on the pads. Apply flux to the area, then use a desoldering wick and soldering iron (set to 300°C) to soak up excess solder. The pads should be clean and flat for the new component.

Step 5: Place the New Component

Apply a thin layer of solder paste to the pads if working with SMT parts. Position the new component carefully using tweezers, ensuring correct alignment. Double-check the orientation before proceeding.

Step 6: Solder the New Component

Use the hot air gun again at 300°C-350°C to reflow the solder paste. Move the nozzle back and forth over the component for 10-15 seconds until the solder melts and forms a shiny connection. Let the board cool naturally—don’t blow on it, as this can create weak joints.

Step 7: Inspect Your Work

Check the solder joints under a magnifying glass. They should be smooth and shiny, with no gaps or excess solder. Test the PCB to ensure the new component works as expected.

Tips for Successful Hot Air Rework for Beginners

Mastering hot air rework for beginners takes practice, but these tips will help you avoid common mistakes and improve your skills:

- Start with Low Heat: Begin at a lower temperature (around 300°C) and increase if needed. Too much heat can damage components or lift PCB traces, which are often only 0.035 mm thick in standard boards.

- Protect Nearby Components: Use heat-resistant tape or aluminum foil to shield adjacent parts from hot air. Some components, like plastic connectors, can melt at temperatures as low as 150°C.

- Keep the Nozzle Moving: Constant motion prevents overheating one area. Aim for a steady back-and-forth or circular pattern.

- Practice on Scrap Boards: Before working on a valuable PCB, test your skills on an old or damaged board. This builds confidence without risking important projects.

- Use Flux Generously: Flux reduces oxidation and helps solder flow, leading to cleaner joints. A small dab can make a big difference.

Common Challenges in PCB Rework and How to Overcome Them

As a beginner, you might face a few hurdles during PCB rework. Here’s how to handle them:

1. Overheating the PCB

If the board starts to discolor or traces lift, you’re applying too much heat. Lower the temperature by 50°C and reduce exposure time. Most PCBs can handle short bursts of heat up to 260°C, but prolonged exposure causes damage.

2. Component Misalignment

If the new component shifts during soldering, reheat with hot air and reposition it with tweezers. Ensure the solder paste is evenly applied to prevent uneven melting.

3. Excess Solder Bridges

Solder bridges happen when too much solder connects adjacent pins. Use a desoldering wick and flux to remove the excess. For tiny ICs with pin spacing as small as 0.5 mm, this is a common issue but easy to fix with patience.

Safety Precautions for Using a Rework Station

Working with a rework station involves high temperatures and potential hazards. Keep these safety tips in mind:

- Always work in a ventilated space to avoid inhaling fumes from solder or flux.

- Wear heat-resistant gloves if handling hot components or boards.

- Keep the hot air gun and soldering iron on their stands when not in use to prevent burns or fires.

- Unplug the station when finished to avoid accidental activation.

Choosing the Right Rework Station for Beginners

When selecting a rework station, focus on features that match your skill level and needs. Here are key factors to consider:

- Temperature Control: Look for adjustable settings with a range of at least 200°C to 450°C for versatility.

- Airflow Settings: A hot air gun with adjustable airflow (20-120 L/min) helps manage heat distribution.

- 2-in-1 Design: Stations with both a soldering iron and hot air gun are ideal for beginners handling both SMT and THT components.

- Digital Display: A clear readout of temperature and airflow makes it easier to maintain precision.

Starting with a reliable rework station sets the foundation for successful projects and builds confidence as you learn.

Conclusion: Start Your PCB Rework Journey Today

Using a PCB rework station for component replacement doesn’t have to be intimidating. By understanding rework station basics, following a clear component replacement guide, and practicing hot air rework for beginners, you can tackle repairs and upgrades with ease. Remember to start small, use the right tools, and prioritize safety as you build your skills.

With this guide and a bit of hands-on practice, you’ll be well on your way to mastering PCB rework for beginners. Whether you’re fixing a broken device or experimenting with custom designs, the ability to replace components opens up endless opportunities in electronics. Grab your rework station and get started today!

ALLPCB

ALLPCB