In the world of printed circuit board (PCB) manufacturing, precision is everything. Two critical processes that directly impact the quality and reliability of a PCB are PCB direct imaging and solder mask application. If you're searching for ways to improve accuracy and efficiency in PCB production, particularly with techniques like LDI solder mask application or optimizing solder mask with direct imaging, you're in the right place. This guide will walk you through the essentials of these processes, their benefits, and how they work together to enhance PCB performance.

Whether you're an engineer, designer, or manufacturer, understanding PCB manufacturing solder mask techniques and the role of direct imaging can help you achieve better results. Let’s dive into the details of these technologies and explore actionable tips for improving solder mask accuracy.

What is PCB Direct Imaging and Why Does It Matter?

PCB direct imaging, often referred to as Laser Direct Imaging (LDI), is a cutting-edge technology used to create highly precise patterns on a PCB. Unlike traditional methods that rely on phototools or film masks, LDI uses a laser to directly transfer digital design data onto the board. This eliminates alignment errors and improves the accuracy of features like traces, pads, and vias.

In numbers, LDI can achieve resolutions as fine as 25 microns, making it ideal for high-density interconnect (HDI) boards where space is limited. By removing the need for physical masks, it also reduces production time by up to 30% in some cases, depending on the complexity of the design. This precision and efficiency make it a game-changer for modern PCB manufacturing.

Understanding Solder Mask Application in PCB Manufacturing

A solder mask is a thin protective layer applied over the copper traces of a PCB. Its primary role is to prevent solder bridges during assembly, protect the board from oxidation, and insulate the copper to avoid short circuits. Typically made of a polymer material, the solder mask is applied using various methods, including screen printing, curtain coating, or spray coating, before being cured with heat or UV light.

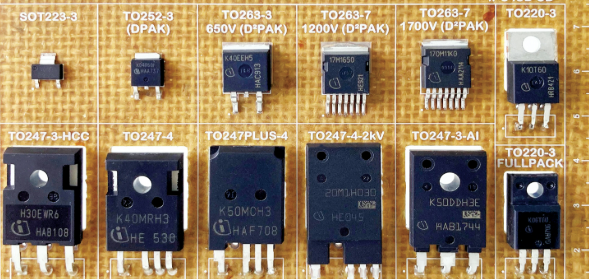

In PCB manufacturing solder mask processes, accuracy is crucial. Misalignment as small as 0.05mm can cover part of a pad, leading to weak solder joints or assembly failures. This is especially critical in surface-mount technology (SMT) designs with fine-pitch components where pad spacing might be as tight as 0.4mm. A well-applied solder mask ensures reliability and durability, protecting the board throughout its lifecycle.

How PCB Direct Imaging Enhances Solder Mask Application

The integration of PCB direct imaging solder mask techniques has revolutionized how manufacturers apply this protective layer. With LDI, the solder mask pattern is directly imaged onto the PCB using a laser, ensuring pinpoint accuracy. This is a significant improvement over older methods where misalignments in phototools could lead to defects.

For instance, in HDI boards, where component density is high, LDI can achieve precise solder mask openings with tolerances below 50 microns. This level of control is vital for preventing issues like solder bridging or insufficient coverage. Additionally, LDI allows for quick adjustments to the design data without the need to create new physical masks, reducing lead times by up to 20% in complex projects.

By optimizing solder mask with direct imaging, manufacturers can produce boards that meet stringent quality standards, even for advanced applications like flexible PCBs or mini-LED backlight units. The result is a more reliable product with fewer defects during assembly.

Key Benefits of LDI Solder Mask Application

Using LDI solder mask application offers several advantages for PCB production. Here are some of the standout benefits:

- Enhanced Precision: LDI ensures exact alignment of the solder mask, reducing errors to below 0.02mm in many cases. This is critical for fine-pitch components and high-density designs.

- Reduced Production Time: Without the need for physical masks, setup times are shorter, speeding up the manufacturing process by up to 25% for multilayer boards.

- Cost Efficiency: Eliminating phototools lowers material costs and reduces waste, providing a lower total cost of ownership over time.

- Flexibility: Digital imaging allows for rapid design changes, making it easier to adapt to custom or specialized requirements, such as white solder masks for LED applications.

- Improved Quality: Consistent imaging quality minimizes defects, ensuring the solder mask performs its protective role effectively.

These benefits make LDI an essential tool for manufacturers aiming to stay competitive in a fast-paced industry.

Steps in Solder Mask Application Using Direct Imaging

The process of applying a solder mask with direct imaging involves several key steps. Understanding these can help you appreciate the precision and care required for optimal results. Here’s a breakdown:

- Design Data Preparation: The PCB design file, including the solder mask layer, is prepared digitally. This file dictates where the mask will be applied and where openings for pads and vias will remain.

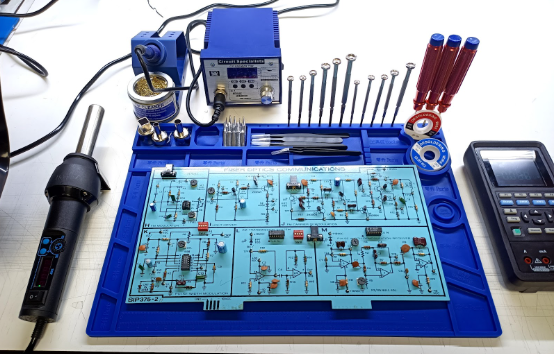

- Board Cleaning: The PCB surface is cleaned to remove contaminants like dust or oils, ensuring proper adhesion of the solder mask material.

- Solder Mask Coating: A liquid or dry film solder mask material is applied to the board using methods like screen printing or spray coating.

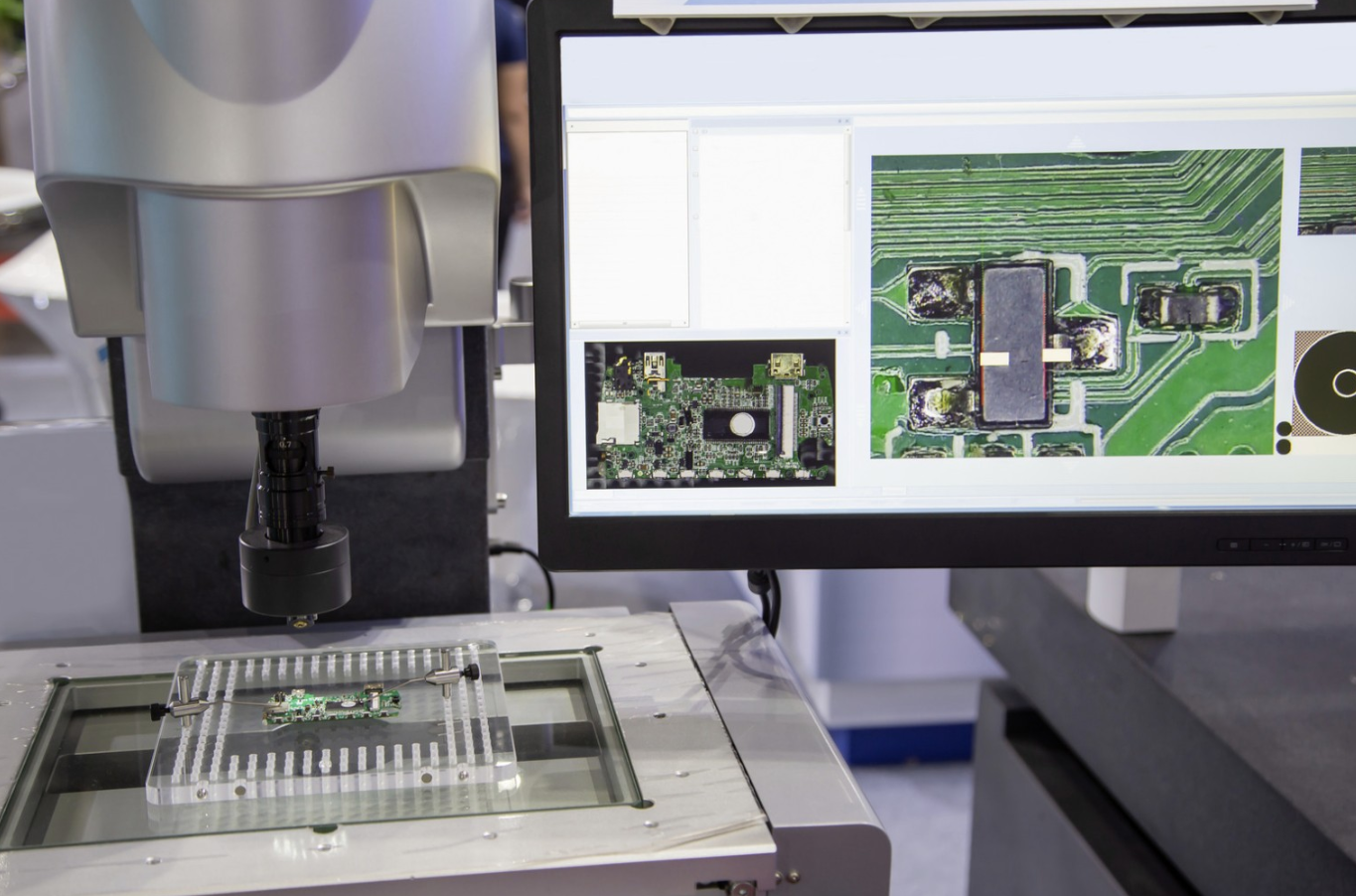

- Direct Imaging with LDI: Using laser technology, the solder mask pattern is directly imaged onto the board based on the digital design data. This step defines the areas to be exposed or protected.

- Development: Unexposed areas of the solder mask are removed, leaving precise openings for soldering.

- Curing: The solder mask is cured using heat or UV light to harden it and ensure it bonds securely to the PCB. This step enhances durability, with curing temperatures often reaching 150°C for 30-60 minutes.

- Inspection: The board is inspected for alignment accuracy and defects, often using automated optical inspection (AOI) systems to ensure quality.

Each step is critical to achieving a flawless solder mask layer, and LDI plays a pivotal role in ensuring precision during the imaging phase.

Tips for Optimizing Solder Mask with Direct Imaging

To get the most out of optimizing solder mask with direct imaging, consider these practical tips for your manufacturing process:

- Use High-Quality Design Data: Ensure your digital files are accurate and free of errors. Small discrepancies in the design can lead to significant issues during imaging.

- Choose the Right Solder Mask Material: Select a material compatible with LDI processes. For example, liquid photoimageable (LPI) solder masks work well with laser imaging and provide high resolution.

- Calibrate Equipment Regularly: Maintain your LDI systems to ensure consistent laser accuracy. Miscalibration can result in alignment errors as small as 0.01mm, which can still impact fine-pitch designs.

- Monitor Environmental Conditions: Temperature and humidity can affect solder mask adhesion and curing. Keep the production area within recommended ranges, typically 20-25°C and 40-60% humidity.

- Perform Test Runs: Before full-scale production, run small batches to verify alignment and coverage. This can save time and resources by catching issues early.

Implementing these strategies can significantly improve the quality of your solder mask application and overall PCB reliability.

Challenges in Solder Mask Application and How LDI Helps

Despite advancements, solder mask application can still present challenges. Common issues include misalignment, incomplete coverage, and defects like pinholes or bubbles in the mask layer. These problems can lead to solder bridges, oxidation, or even board failure during operation.

By improving solder mask accuracy with LDI, many of these challenges are mitigated. The laser’s precision ensures that openings for pads are perfectly aligned, even in designs with spacing as tight as 0.3mm. Additionally, LDI’s digital nature eliminates the variability introduced by physical masks, reducing the risk of human error during setup. For complex boards, such as those used in automotive or medical devices, this level of control is indispensable.

Applications of PCB Direct Imaging and Solder Mask in Various Industries

The combination of PCB direct imaging and solder mask application is vital across multiple industries. Here are a few examples of how these technologies are applied:

- Consumer Electronics: Smartphones and tablets rely on HDI boards with fine-pitch components. LDI ensures precise solder mask application for reliable performance in compact designs.

- Automotive: PCBs in vehicles must withstand harsh conditions. Accurate solder masks protect against moisture and vibration, with LDI enabling tight tolerances for multilayer boards.

- Medical Devices: Equipment like pacemakers requires absolute reliability. Direct imaging ensures defect-free solder masks, critical for patient safety.

- LED Technology: For mini-LED backlight units, specialized white solder masks are used. LDI supports unique materials and patterns for optimal light diffusion.

These diverse applications highlight the importance of precision in PCB manufacturing and the role of technologies like LDI in meeting industry demands.

Future Trends in PCB Direct Imaging and Solder Mask Application

As technology evolves, so do the methods for PCB production. The future of PCB direct imaging solder mask application looks promising with trends like:

- Higher Resolutions: Advances in laser technology may push resolutions below 10 microns, enabling even denser designs.

- Automation: Fully automated LDI systems integrated with AI could further reduce errors and improve throughput by up to 40%.

- Eco-Friendly Materials: New solder mask materials with lower environmental impact are being developed, compatible with direct imaging processes.

- Customization: Digital imaging will continue to support rapid prototyping and small-batch production, catering to niche markets with unique requirements.

Staying ahead of these trends can position manufacturers to meet future challenges and deliver cutting-edge solutions.

Conclusion: Elevating PCB Quality with Direct Imaging and Solder Mask

In summary, PCB direct imaging and solder mask application are two pillars of modern PCB manufacturing that work hand-in-hand to ensure precision, reliability, and efficiency. By leveraging technologies like LDI, manufacturers can achieve unparalleled accuracy in solder mask placement, addressing the demands of complex designs and high-performance applications.

Whether you're focused on LDI solder mask application, PCB manufacturing solder mask processes, or improving solder mask accuracy, adopting direct imaging offers a clear path to better results. With the right tools, materials, and practices, you can optimize your production process and deliver PCBs that meet the highest standards of quality.

Embrace these technologies to stay competitive and build boards that power the innovations of tomorrow.

ALLPCB

ALLPCB