Overview

With the rapid development of new energy vehicles, requirements for drive motor peak power, operating efficiency, response speed, and vibration and noise have increased. As a result, drive motors are moving toward oil cooling, flat-wire windings, and multi-function integration.

Oil cooling for drive motors

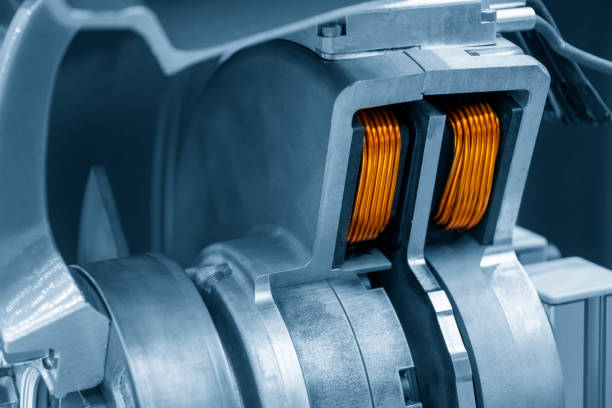

Oil cooling can directly contact internal motor components and is the preferred cooling method. Drive motor cooling systems are mainly divided into air cooling and liquid cooling. Air cooling uses air as the coolant and dissipates heat through convection; it has a simple structure, low cost, and easy maintenance, but limited cooling performance, so it is mainly used for low-power electric vehicles. Liquid cooling can be implemented with water or oil. Water cooling is low cost and nonpolluting, but because of insulation requirements inside the motor, water cooling is limited to an external water jacket on the motor housing. Oil cooling, owing to its electrical insulation properties, can perform direct internal contact cooling, yielding better results. Therefore, oil cooling has become the preferred method for drive motor cooling.

Indirect oil cooling via a hollow motor shaft provides better performance. Oil cooling can be categorized as direct or indirect depending on whether the coolant contacts the internal electromagnetic windings. Direct oil cooling includes immersion and spray types. Immersion cooling fills the motor interior with insulating oil to immerse the rotor and stator, improving internal heat transfer coefficients; however, immersion introduces rotor-oil friction losses that reduce motor efficiency. Spray cooling pumps transformer oil onto fixed blades attached to the rotor so that rotation splashes oil onto stator end windings and other components for cooling. Indirect oil cooling circulates cooling oil through a hollow motor shaft and the motor housing, removing internal heat while causing minimal rotor friction losses, which is a clear advantage.

Flat-wire drive motors

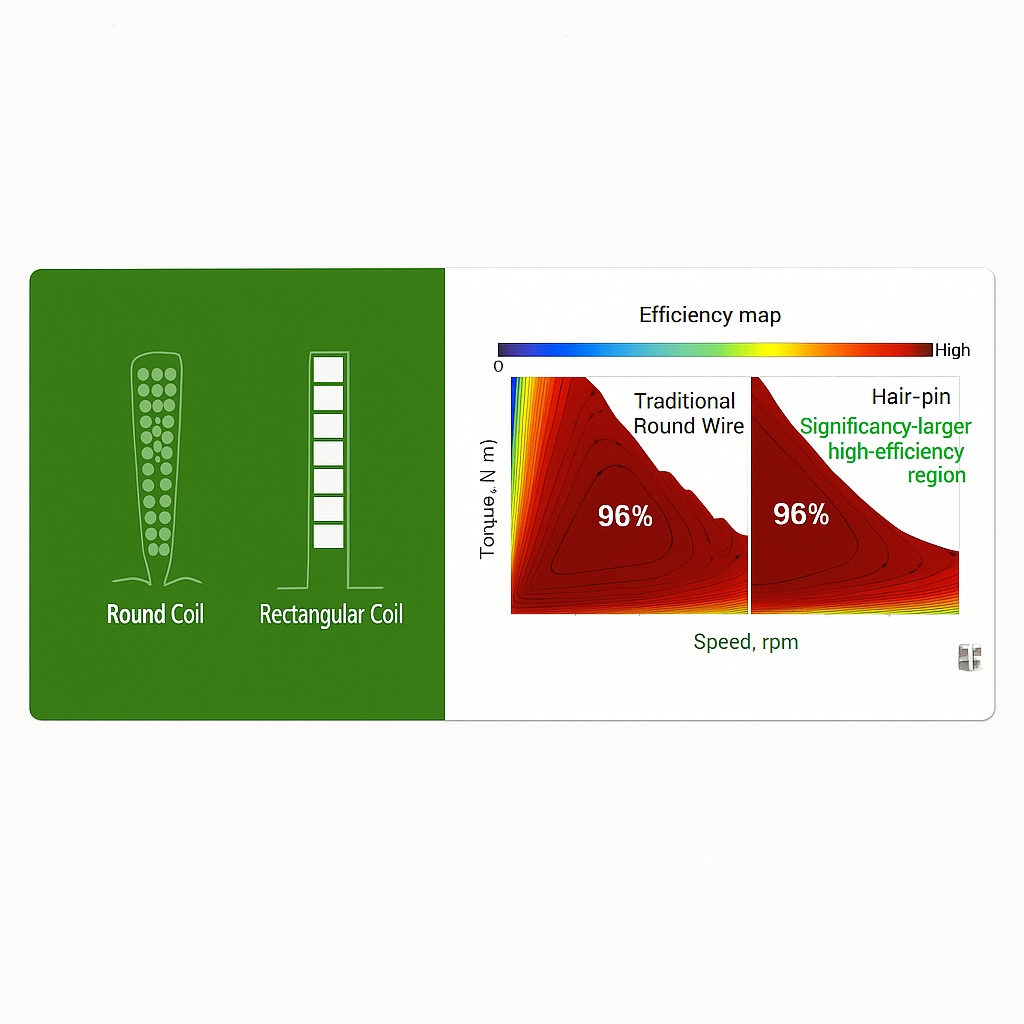

Demand for higher power and economies of scale are driving adoption of flat-wire motors. Historically, most drive motor windings used round copper wire; round wire tolerances are less strict and small-batch production can be done manually, which made it cost-effective. As the new energy vehicle era advances, motors are trending toward higher power and higher speed, increasing efficiency requirements. Flat-wire windings are becoming mainstream. In 2021, flat-wire motor penetration reached 27%, and as industry scale expands, adoption is expected to continue accelerating.

Flat-wire motors achieve higher slot fill and better drive efficiency. The main difference between flat and round wire is cross-sectional shape. Winding slots filled with round wire have lower fill factors, while flat wire reduces gaps and increases slot fill. According to published information, flat-wire windings can pack 20% to 30% more conductor in the same space, increasing slot fill by about 20% and improving peak machine efficiency by roughly 2%. Flat-wire motors also maintain higher efficiency over a broader high-power range, which is favorable for vehicle range.

Multi-function integration of drive systems

Integrated e-drive systems offer clear advantages and align with current development trends. A multi-function integrated e-drive consolidates the drive motor, motor controller, reducer, DC/DC converter, onboard charger, high-voltage distribution box, and other components into a shared housing and wiring harness to achieve weight reduction, lower cost, and higher efficiency. Compared with distributed architectures, integration reduces volume and saves vehicle space, facilitating modular design and cost reduction. For example, a commonly used three-in-one configuration (drive motor + motor controller + reducer) can share oil cooling circuitry; lubricant in the reducer can serve as the motor cooling oil, making the integration benefits even more pronounced.

ALLPCB

ALLPCB