Overview

Tactile sensors convert environmental stimuli into electrical signals to perceive and quantify environmental information, offering broad application potential. Biomimetic robots and wearable devices are moving toward increased intelligence, which places high demands on the performance of tactile sensor arrays.

This article reviews recent advances in tactile sensor arrays, and details major patterning and fabrication methods, including screen printing, 3D printing, laser micromachining, and textile techniques. It also systematically describes strategies to reduce crosstalk in flexible high-density sensor arrays from both structural design and circuit design perspectives. To improve applicability, a scalable self-powered sensing integration scheme is briefly introduced. Finally, methods based on machine learning and neural networks for extracting richer information from tactile signals are discussed.

High-resolution Array Fabrication Techniques

For regions with dense receptor distribution such as fingertips, spatial resolution can reach about 1 mm and response time around 15 ms, which is critical for applications like Braille recognition and precise object contour detection. Current patterning methods for tactile sensors mainly include screen printing, 3D printing, laser micromachining, and textile techniques.

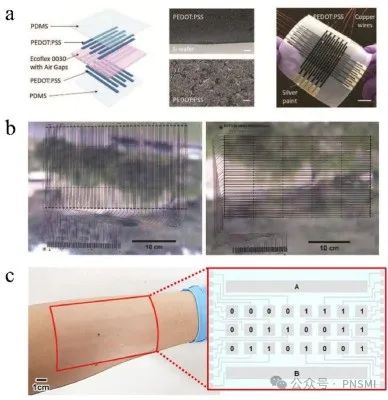

Screen Printing

Screen printing can achieve printing precision on the order of 100 um. The technique is mature, simple, efficient, low-cost, and suitable for mass production. It is mainly used to rapidly fabricate patterned electrodes in tactile sensor arrays. One reported process uses patterned polyester tape as a mask for screen printing and silver nanowires as electrode material. The resulting array has a unit pitch of 5 mm, and the linear electrodes connecting each unit to external wires are only 1 mm wide.

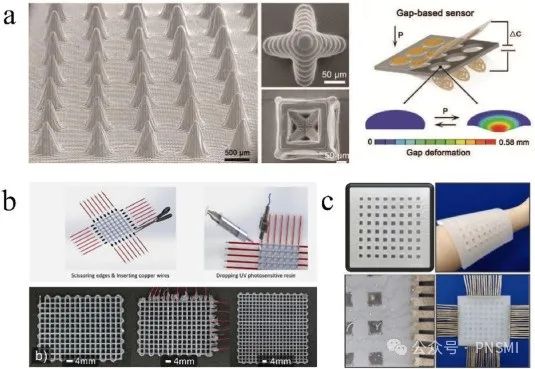

3D Printing

3D printing is easy to operate and can directly print electrodes or sensitive materials with microstructures as needed. It also supports mold customization and assists in shaping materials such as gels or uncured resins. Reported work used 3D printing to produce a template with a designed pattern comprising an 8 x 8 sensor array and serpentine electrode lines. A gel mixture was cast into the template and air-dried at room temperature to yield a soft, elastic patterned elastomer for a triboelectric tactile sensor array.

Laser Micromachining

Laser micromachining is a maskless, high-throughput technique suitable for mass production and helps fabricate sensors with high sensitivity, high spatial resolution, and high reliability. Laser processing can induce chemical reactions in substrate materials to create desired sensing layers, allowing direct patterning on the substrate and eliminating transfer and pattern-processing steps. Laser direct writing has been used to develop a flexible high-resolution triboelectric sensor array. A 16 x 16 array was fabricated with a resolution reported as 8 dpi, achieving real-time visualization of multipoint touch, sliding, and finger motion tracking.

Textile Techniques

Embedding electrodes and sensing materials into textile fibers yields functional fabrics with tactile response, offering washability, breathability, extreme stretchability, and robustness. Textile-based sensors are more suitable for wearable applications and can be integrated into conventional clothing for improved comfort and airflow. However, smart textiles often face challenges such as complex fabrication processes and low sensitivity, limiting their wide application in tactile sensing systems.

Crosstalk Mitigation Strategies

Sensor Structural Optimization

To reduce deformation of non-pressed units, a viable solution is to optimize node layout to make sensing units spatially independent. One study designed a MoS2-based ultra-thin conformal tactile sensor in a 4 x 4 array over a large area (2.2 cm x 2.2 cm), with each cell sized 2.10 mm x 1.85 mm. Reasonable distribution of sensing units substantially mitigated crosstalk.

Another approach to suppress stress-induced deformation of adjacent sensing units is to add mechanical isolation structures such as grooves or supporting features. Simulation and experiments showed that introducing spacing between units in a 10 x 10 tactile sensor array effectively suppressed crosstalk and significantly improved spatial resolution.

Circuit Design Improvements

Two widely used electrical methods are the voltage-feedback method and the zero-potential method. The voltage-feedback method introduces feedback loops to cancel crosstalk, keeping unscanned rows and columns at the same potential provided by the feedback voltage. The zero-potential method drives operational amplifiers to create a virtual ground or grounds non-scanned electrodes via multiplexers, keeping all non-scanned drive electrodes at zero potential. An improved circuit based on zero-potential crosstalk suppression implemented a decoding-transistor scanning architecture to make the method suitable for large arrays. Although the zero-potential approach requires more complex circuitry, it can achieve higher detection accuracy.

Multifunctional Sensor Integration Strategies

Integrating materials with different sensing functions through structural design is a method to create multimodal tactile sensor arrays. Reported work demonstrated a flexible and stretchable multifunctional sensor array combining distributed and stacked layouts to enable simultaneous real-time monitoring of temperature, humidity, UV, magnetic field, strain, pressure, and proximity. Carbon-black–PDMS composites were used as multimodal sensing material to fabricate a cross-reactive sensing matrix with high sensitivity and fast response to strain, pressure, bending, and temperature stimuli. Machine learning algorithms based on bag-of-features models were used to distinguish different stimuli.

Deep Mining of Tactile Information and Applications

Information from tactile sensors can be further mined using machine learning and neural networks to extract embedded details such as object type and shape, contact surface vibration frequencies, and to monitor or analyze human health. Tactile sensing can be applied for real-time analysis of human motion and grip force to obtain detailed motion information. In visual-haptic perception, researchers combined electrooculography and tactile sensing to develop a collaborative interface for fast and accurate 3D human-machine interaction.

Conclusion and Outlook

Tactile sensors still face significant challenges. First, signals simultaneously acquired by sensor arrays contain rich information such as pressure, shear, and temperature, so effective decoupling of interfering and crosstalk signals is necessary. Second, environmental factors like temperature, humidity, and vibration can degrade sensor performance and affect detection accuracy; improving long-term stability under complex conditions is urgent. Third, although tactile sensors can now be manufactured from fully flexible materials, related data acquisition and transmission circuits are still typically rigid, impacting overall wearability. Therefore, developing flexible and stretchable circuitry is necessary for applying flexible tactile sensors in wearable electronics, intelligent robots, and human-machine interaction systems.

ALLPCB

ALLPCB