Choosing the right material for your printed circuit board (PCB) is a critical decision that directly impacts manufacturing cost. Whether you're working on a budget-friendly project or a high-performance design, the PCB substrate cost can vary widely based on materials like FR4, Rogers, or other high-frequency options. In this comprehensive guide, we’ll explore how PCB material selection influences manufacturing expenses, breaking down the costs of popular substrates and offering insights into balancing performance with affordability.

At the core, the choice of material affects not just the upfront PCB material cost but also factors like production complexity, durability, and application suitability. From the widely used and cost-effective FR4 to the premium Rogers materials for high-frequency designs, understanding these options can help you make informed decisions. Let’s dive into the details of how materials like these shape your project’s bottom line and performance.

Why PCB Material Selection Matters for Cost and Performance

The foundation of any PCB is its substrate material, which serves as the base for mounting components and routing electrical signals. The material you choose determines not only the PCB substrate cost but also how well the board performs under specific conditions like heat, frequency, or mechanical stress. A poor material choice can lead to higher manufacturing costs due to rework, failures, or the need for specialized processes.

For instance, a simple consumer electronics project might thrive on a low-cost FR4 board, while a high-frequency application like a 5G antenna requires a material with superior signal integrity, such as Rogers laminates, despite the higher Rogers PCB cost. By understanding the trade-offs between cost and performance, you can select a material that aligns with both your budget and technical needs.

Breaking Down Common PCB Materials and Their Costs

Let’s take a closer look at the most common PCB materials and how their properties influence manufacturing expenses. We’ll focus on FR4, Rogers, and other substrates often used in high-frequency applications, analyzing their cost structures and use cases.

FR4: The Cost-Effective Standard for Most Projects

FR4 is the most widely used PCB material, known for its affordability and versatility. Made from woven fiberglass and epoxy resin, FR4 offers a good balance of mechanical strength, thermal stability, and electrical insulation. The FR4 cost typically ranges from $0.50 to $2.00 per square foot for standard thicknesses (like 1.6mm), making it a go-to choice for low to medium-complexity designs.

However, the low FR4 cost comes with limitations. Its dielectric constant (Dk) of around 4.5 and dissipation factor (Df) of 0.02 make it less suitable for high-frequency applications above 1 GHz, as signal loss becomes significant. Manufacturing with FR4 is straightforward, which keeps production costs down, but if your design requires tighter impedance control or high-speed signals, you might face additional expenses for testing or redesigns.

For general-purpose electronics like power supplies or consumer gadgets, FR4 remains the most economical option. Its widespread availability and compatibility with standard fabrication processes mean you’re unlikely to encounter unexpected PCB material cost spikes during production.

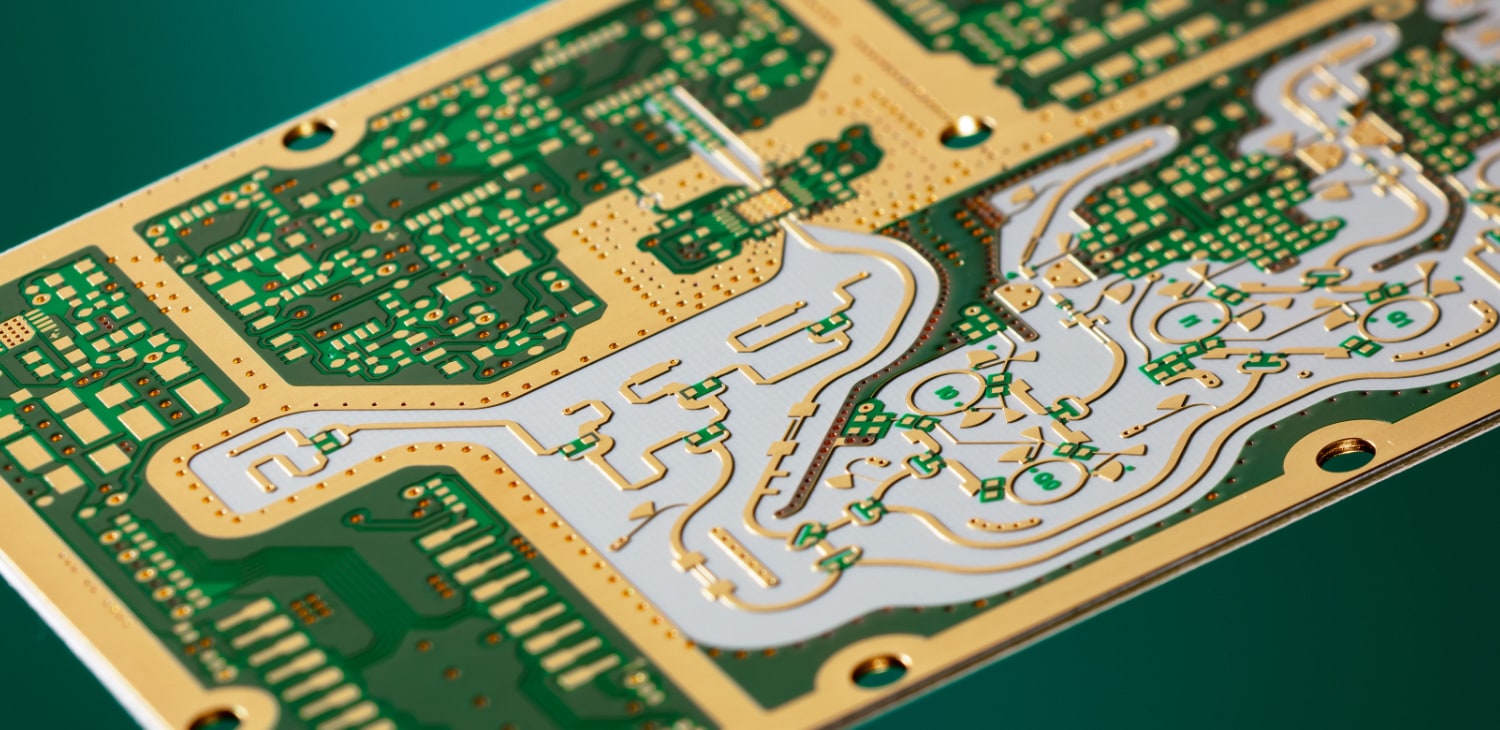

Rogers Materials: Premium Performance at a Higher Cost

For high-frequency and high-speed applications, Rogers laminates are often the material of choice. These substrates are engineered for low signal loss and stable dielectric properties, with Dk values ranging from 2.2 to 10.2 and Df as low as 0.0009 in some variants. This makes them ideal for RF circuits, microwave designs, and 5G technologies. However, the Rogers PCB cost is significantly higher, often starting at $5 to $20 per square foot or more, depending on the specific grade and thickness.

The elevated Rogers PCB cost stems from the specialized manufacturing processes required, including precise handling to maintain material integrity and advanced testing for signal performance. Additionally, Rogers materials are less common than FR4, so sourcing them in smaller quantities can drive up expenses. If your project involves frequencies above 5 GHz or requires minimal signal distortion, the investment in Rogers can save costs in the long run by reducing failures and ensuring reliability.

Other High-Frequency Materials and Their Cost Implications

Beyond FR4 and Rogers, other high-frequency PCB materials like PTFE (Teflon-based) or ceramic-filled laminates are used in niche applications. These materials often have even higher high-frequency PCB costs, sometimes exceeding $30 per square foot, due to their rarity and the complexity of working with them. For example, PTFE offers excellent thermal and electrical properties with a Dk as low as 2.1, but it’s soft and prone to deformation, requiring specialized fabrication techniques that add to manufacturing expenses.

High-frequency PCB cost is also influenced by the need for tighter tolerances in layer alignment and impedance matching. These materials are typically reserved for cutting-edge applications like aerospace or medical imaging, where performance justifies the price tag. If your project doesn’t demand such extreme specifications, opting for a more affordable material can significantly lower your PCB substrate cost.

Factors Beyond Material Type That Impact PCB Manufacturing Cost

While the choice of substrate is a major driver of PCB material cost, several other factors related to material selection can affect the overall manufacturing budget. Understanding these can help you optimize your design for cost efficiency without compromising quality.

Layer Count and Material Thickness

The number of layers in your PCB and the thickness of the substrate directly influence costs. For instance, a multilayer board using FR4 might cost $1.50 per square foot for a 4-layer design, but this can jump to $3.00 or more for an 8-layer board due to increased material usage and processing time. With premium materials like Rogers, the cost per layer rises even faster because of the base material’s higher price.

Thicker substrates also add to the expense, as they require more raw material and can complicate drilling and lamination processes. A standard 1.6mm FR4 board is cheaper to produce than a 2.4mm board, for example. When designing, consider whether the extra thickness or layers are necessary for your application to avoid unnecessary PCB substrate cost increases.

Thermal and Mechanical Requirements

Materials are often chosen based on their ability to handle heat or mechanical stress, which can impact manufacturing costs. FR4, with a glass transition temperature (Tg) of around 130-140°C, is suitable for most applications but may deform under high heat. High-Tg FR4 variants (Tg of 170°C or more) or Rogers materials (Tg up to 280°C) are more expensive but necessary for environments with extreme temperatures, such as automotive or industrial systems.

Choosing a material with better thermal properties might increase the upfront FR4 cost or Rogers PCB cost, but it can reduce expenses related to cooling solutions or board failures. Similarly, if your design requires flexibility or high durability, opting for materials like polyimide can drive up costs due to specialized processing needs.

Signal Integrity and Impedance Control Needs

For high-speed or high-frequency designs, maintaining signal integrity and precise impedance control is crucial. Materials like Rogers offer low dielectric loss and consistent Dk values, which simplify achieving impedance targets (e.g., 50 ohms for RF signals). However, this comes at a higher high-frequency PCB cost. With FR4, achieving the same level of control often requires additional design adjustments or testing, which can increase manufacturing time and expenses.

If your project operates at lower frequencies (below 1 GHz), FR4 might suffice with proper design techniques, saving you from the premium Rogers PCB cost. Always evaluate the signal speed and frequency requirements before committing to a material to avoid over-specifying and inflating costs.

Balancing Cost and Performance: Tips for Material Selection

Navigating the trade-offs between PCB material cost and performance doesn’t have to be daunting. Here are some practical strategies to help you choose the right substrate while keeping your budget in check.

First, define the specific requirements of your project. If your design operates at low frequencies and doesn’t face extreme conditions, sticking with FR4 can minimize your FR4 cost and overall expenses. For applications pushing beyond 1 GHz or requiring minimal signal loss, investing in a high-frequency material like Rogers can prevent costly redesigns or failures.

Second, consider hybrid approaches for complex designs. Some projects use a mix of materials, such as FR4 for power layers and Rogers for high-frequency signal layers. This can reduce the overall PCB substrate cost while still meeting performance needs, though it may increase manufacturing complexity slightly.

Lastly, work closely with your fabrication partner to understand material availability and processing capabilities. Sourcing less common materials in small quantities often leads to higher costs due to minimum order requirements. Bulk ordering or choosing widely available substrates can help manage expenses without sacrificing quality.

Real-World Examples of Material Selection Impacting Cost

To illustrate how material choice affects manufacturing cost, let’s look at two hypothetical scenarios. In the first, a company designs a basic IoT sensor board for home automation. Using FR4 at $1.00 per square foot, the material cost for a 10,000-unit run of small boards (0.1 square feet each) comes to $1,000. The straightforward manufacturing process keeps additional expenses low, aligning with the project’s tight budget.

In contrast, a telecommunications firm develops a 5G base station component requiring excellent signal integrity at 28 GHz. They opt for a Rogers laminate costing $15 per square foot. For the same 10,000-unit run of 0.1 square foot boards, the material cost alone is $15,000. While the high-frequency PCB cost is substantial, the material ensures reliable performance, avoiding potential losses from signal degradation or customer dissatisfaction.

These examples highlight how PCB material cost scales with performance demands. Tailoring your choice to the application is key to avoiding overpaying for unnecessary features or under-specifying and risking failure.

Conclusion: Make Informed Choices to Optimize PCB Costs

The material you select for your PCB plays a pivotal role in determining manufacturing cost and overall project success. From the budget-friendly FR4 cost to the premium Rogers PCB cost for high-frequency applications, each substrate comes with unique benefits and price points. By carefully assessing your design’s requirements—whether it’s signal speed, thermal tolerance, or mechanical strength—you can choose a material that delivers the best value without breaking the bank.

Remember that PCB substrate cost isn’t just about the raw material price. Factors like layer count, manufacturing complexity, and long-term reliability all contribute to the final expense. With a clear understanding of these elements, you can make strategic decisions that balance performance and affordability, ensuring your project meets both technical and financial goals.

At ALLPCB, we’re committed to helping you navigate these choices with expert guidance and high-quality fabrication services. Whether you’re working with standard FR4 or specialized high-frequency materials, our team is ready to support your vision from concept to completion.

ALLPCB

ALLPCB