Introduction

The MAX30205 is a clinical-grade, ±0.1°C precision contact temperature sensor suitable for medical and consumer wearables, from garments and patches to wrist-worn devices. Temperature measurement requires careful consideration when adding this feature. This application note recommends methods for integrating temperature measurement.

Overview

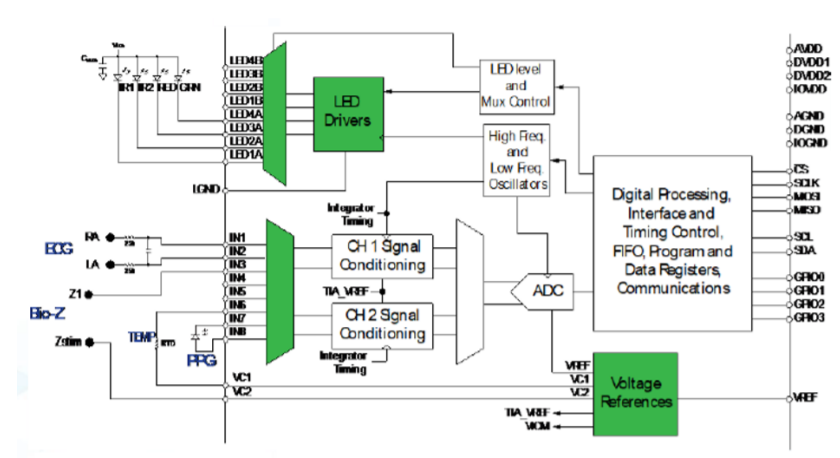

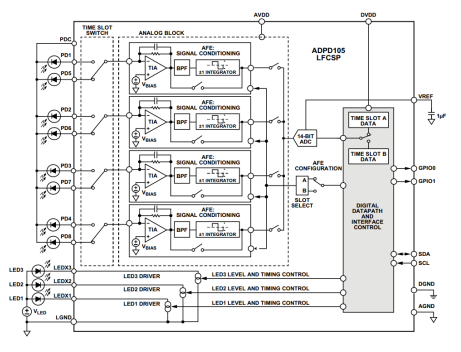

Maxim contact temperature sensors work by connecting a digital temperature device directly to the target surface to measure temperature. Clinical-grade accuracy of ±0.1°C enables reliable monitoring of a person’s health and overall wellbeing. Combining temperature measurements with other physiological signals such as PPG and ECG supports health-related assessments. Some companies use skin surface temperature to estimate core body temperature. Therefore, temperature is an important physiological parameter in the medical and consumer wearable markets.

Guidelines for Wearable Integration

Measuring temperature in wearables is challenging because you must ensure you are measuring the user’s temperature and not the device’s temperature. You must also ensure that electronic components in the wearable do not affect the temperature measurement.

Because of these complexities, product design requires iteration. Several tests and validation protocols should be completed before final industrial design.

For wearables that measure skin surface temperature, consider the following recommendations:

- Maximize skin contact area. Increase the usable thermal capacity of the skin by allowing the device to contact as much skin as possible. This also increases perfusion rate and reduces skin thermal resistance.

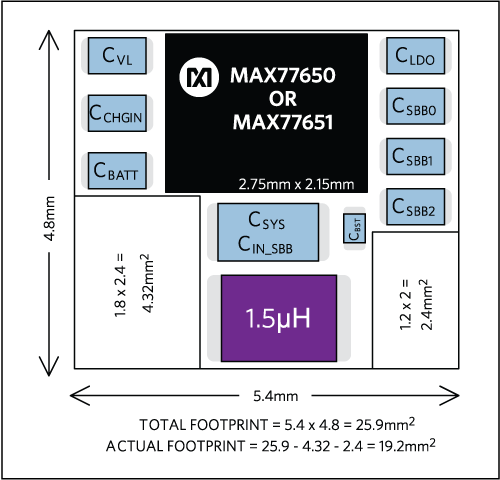

- Minimize system thermal mass. Use the thinnest possible printed circuit board or polyimide flexible circuit to reduce system thermal mass.

- Minimize system losses to the environment through the PCB and enclosure. When designing the PCB, consider the following and use the thinnest copper traces possible (for example, 1/2 oz or less):

- Create openings in the PCB around the temperature sensor, or use a separate small PCB for the sensor.

- Route a thin ground trace and a thin power trace to the sensor chip.

- Do not connect a battery with a higher voltage than the power requirements.

- Minimize power and ground plane layers.

ALLPCB

ALLPCB