As vehicles become more connected and intelligent, the share of automotive electronics and electrical components in a vehicle is increasing. Advanced driver assistance systems and in-vehicle multimedia systems are now influential factors in consumer purchasing decisions. The growing system complexity has driven demand for more sensors and electronic control units (Electronic Control Unit, ECU), such as cameras for autonomous driving, millimeter-wave radar, passenger entertainment screens, HUD head-up displays, engine control modules (ECM), battery management system (BMS) modules for electric vehicles, and around-view monitoring (AVM) modules for 360-degree image fusion. Data indicate a modern luxury vehicle typically contains 70 to 100 ECUs. The traditional distributed electrical/electronic architecture (Electrical/Electronic Architecture, EEA) can no longer meet current requirements for several reasons: 1) inefficient use of distributed compute resources; 2) harness cost and weight disadvantages; 3) inability to support high-bandwidth in-vehicle communication; and 4) challenges in upgrades and maintenance. A centralized EEA and domain controllers have emerged and will likely evolve into central computing platforms.

1. Inefficient use of distributed compute

In distributed architectures, vehicles carry dozens of controllers. To ensure performance and safety, each controller's hardware compute capacity is typically provisioned with headroom relative to the software it runs. As a result, controller capabilities remain siloed and cannot be efficiently coordinated across the vehicle. In a centralized architecture, compute resources can be allocated dynamically—for example, serving driver assistance while driving and providing processing power for in-vehicle gaming while parked.

2. Harness cost and weight disadvantages

A large number of ECUs implies complex and lengthy wiring harnesses. According to industry data, a high-end vehicle uses about 2 km of wiring harness weighing 20 to 30 kg. Cable material accounts for roughly 75% of the harness weight. Introducing a centralized EEA and domain controllers can greatly reduce wiring length and weight.

3. Inability to support high-bandwidth in-vehicle communication

In the ECU era, computing and control were centered on MCU chips and relied on low-speed buses such as CAN, LIN, and FlexRay for transmission. As ECUs proliferated, bus load grew and approached allowable limits, increasing the risk of signal loss, frame drops, and bus congestion, which can create safety hazards. In the domain-controller era, high-performance, highly integrated heterogeneous chips act as domain processors; intra-domain tasks are centrally scheduled, while inter-domain communication uses high-speed links such as Ethernet. Currently, 100 Mbit and 1 Gbit Ethernet are already used in several new models. The per-node cost of automotive Ethernet is higher than CAN and LIN and comparable to FlexRay. Over time, data-rate requirements will drive wider adoption of Ethernet to replace traditional bus systems.

4. System integration and OTA maintenance challenges

ECU development is typically provided by Tier 1 suppliers and integrated by the OEM. This places high demands on OEM system integration and supplier management capabilities. The dispersed layout of many ECUs also complicates support for over-the-air software updates (OTA), increasing the difficulty of post-deployment software maintenance and iteration. OTA has expanded from a niche capability to a widespread practice, and update frequency has increased rapidly. According to official regulatory disclosures in 2021, automakers reported 351 OTA updates, a 55% increase over 2020, involving 34.24 million vehicles, a 307% rise compared with 2020.

Traditional distributed EEA

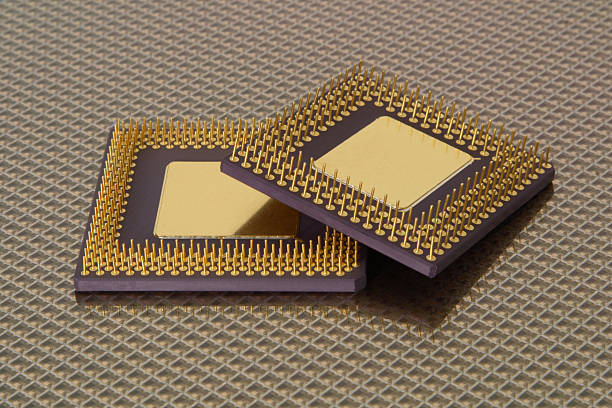

Conventional vehicle electrical/electronic architectures are generally distributed. The control core consists of ECUs connected via CAN and LIN buses, working with sensors, power supplies, communication chips, and actuators to monitor and control vehicle state and functions. Each control function typically has a dedicated ECU; adding a new function usually requires adding another ECU. Thus, increases and upgrades in vehicle intelligence traditionally depend on adding more ECUs and sensors.

ALLPCB

ALLPCB