Introduction

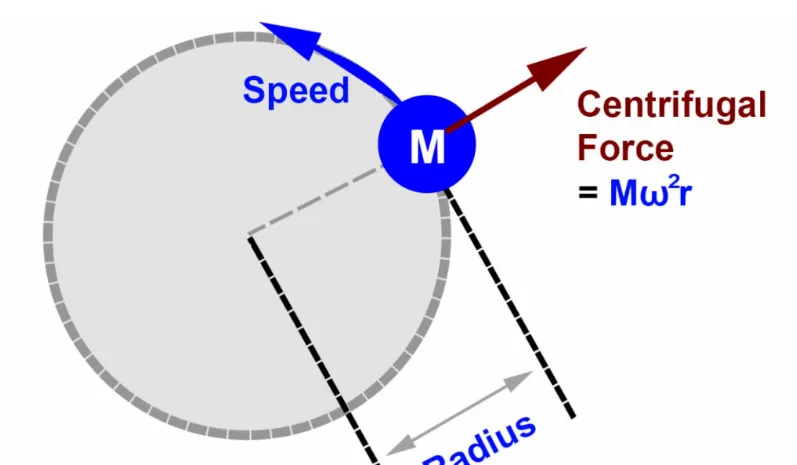

Do rotors for motors running above 20,000 rpm need to be made with carbon fiber winding as a priority? Ensuring rotor structural strength at high speed is not limited to carbon fiber winding. There are also solutions based on ultra-high-strength electrical steel. Centrifugal force depends not only on speed but also on rotor diameter. Considering rim linear velocity as the baseline: for rim speeds up to about 150 m/s, conventional electrical steel is sufficient; around 170 m/s requires high-strength electrical steel; at 180 m/s or higher, either high-strength electrical steel or a carbon fiber solution is needed.

For example, the AVL 30,000 rpm motor has a rotor rim speed of only 155 m/s, so standard electrical steel can handle it; whereas the Hongqi 34,000 rpm motor uses carbon fiber material for the rotor.

Carbon Fiber Winding Technology and Applications

Industry status: small-batch prototypes are feasible, but mass production is challenging. The difficulties include winding equipment cycle time, winding quality, and curing efficiency. Typical curing can take dozens of hours, which prevents high-volume production. Notable examples and techniques mentioned in the industry include:

- Tesla Model S Plaid carbon fiber rotor

- In China, one of the earliest users of carbon fiber in rotors was Zhuhai Yingboer, which used a carbon-fiber protective sleeve process

- Laser in-situ curing technology. Xiaomi described a laser in-situ curing technique that reportedly innovates in resin impregnation and curing methods to reduce curing time while meeting preload and other requirements; a patent was filed for this method

- FAW Hongqi carbon fiber rotor

- Hydrogen storage cylinders

Industry Resources

German ROTH: ROTH developed the first winding machine in 1963. There are nearly 600 machines operating worldwide. ROTH has many supply records in high-pressure cylinder fields such as LPG, CNG, and hydrogen cylinders, with installed equipment performing long-term and passing inspections. ROTH has over 50 years of winding experience and advanced winding machine laboratory equipment. The precision resin bath uses a roller-type impregnation principle with doctor blade and micrometer control of resin content. The bath can be optionally fitted with a programmable automatic resin-content adjustment mechanism, which better controls resin content at different winding stages and improves winding quality. ROTH winding machines can significantly reduce resin dripping during winding.

ComposiCAD is a winding simulation software package that supports virtual prototyping of wound parts and includes post-processing capabilities.

ALLPCB

ALLPCB