In the fast-paced world of electronics, reducing costs while maintaining high performance is a top priority for engineers and manufacturers. One innovative approach gaining traction is the use of embedded components in PCB manufacturing. But are embedded components truly cost-effective? How do they compare to traditional surface mount technology (SMT) in terms of return on investment (ROI)? In this detailed guide, we’ll explore the financial benefits and challenges of embedding components in PCBs, providing a clear cost analysis and actionable insights for optimizing your designs. Whether you're focused on PCB manufacturing costs, embedded component cost analysis, or PCB cost optimization, this blog will help you make informed decisions.

What Are Embedded Components in PCB Manufacturing?

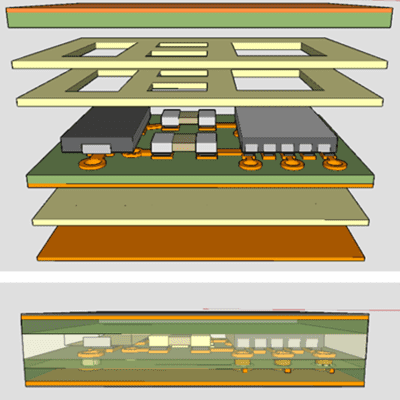

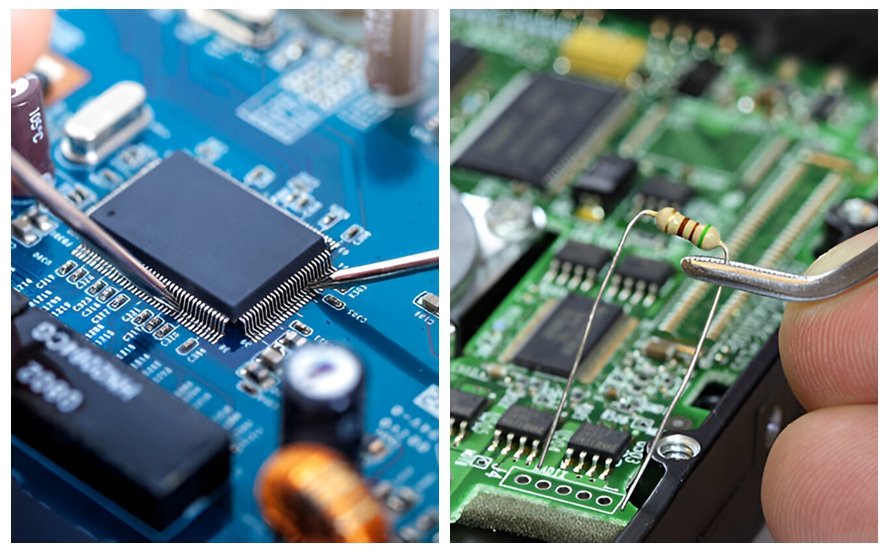

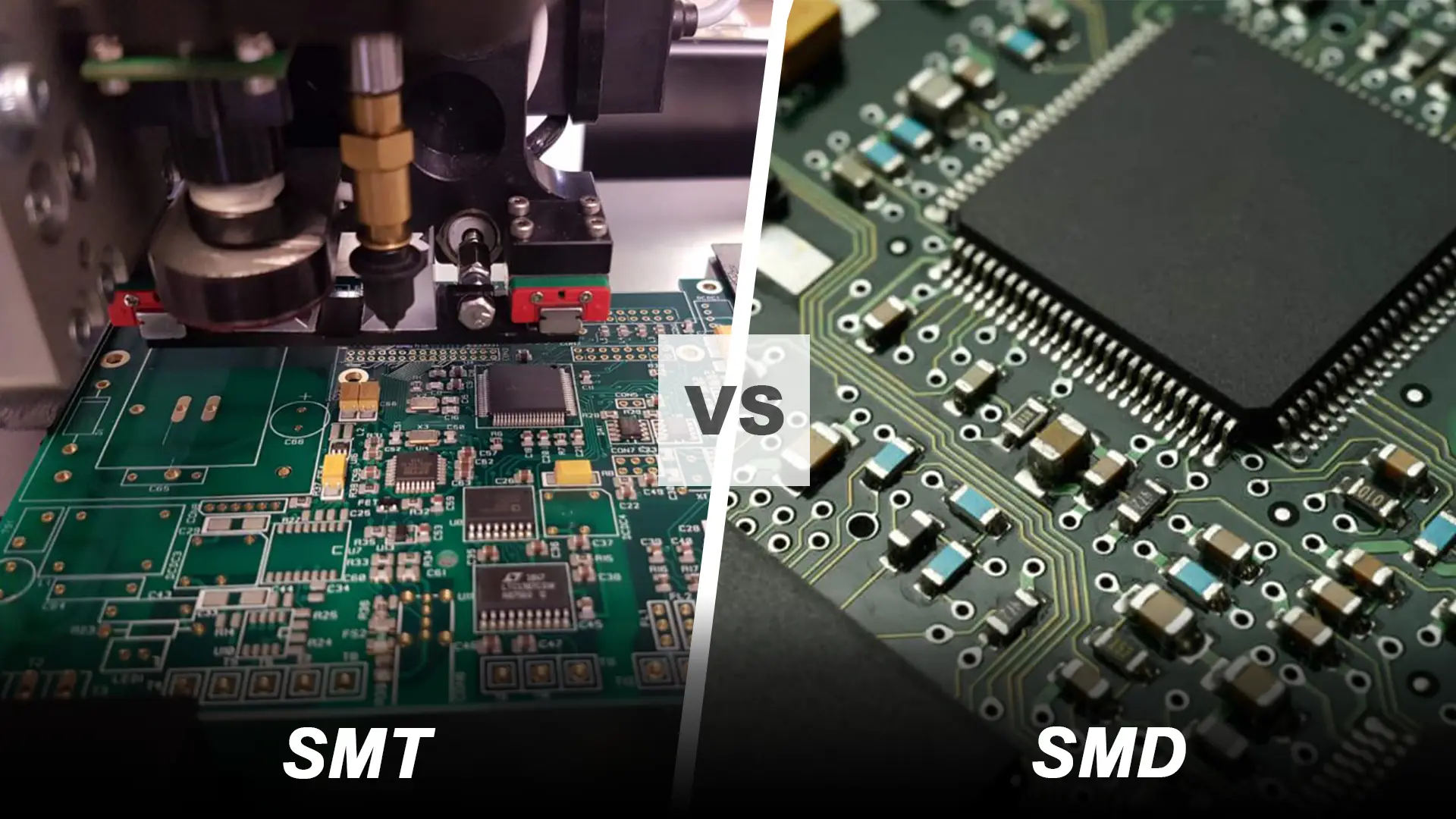

Embedded components are passive or active electronic parts, such as resistors, capacitors, or even small ICs, that are integrated directly into the inner layers of a printed circuit board (PCB) during the manufacturing process. Unlike traditional surface mount technology (SMT), where components are placed on the board’s surface, embedding places these parts within the substrate, often reducing the overall footprint and improving performance.

This technique is particularly useful for high-density designs where space is limited, or in applications requiring enhanced reliability, such as aerospace and medical devices. By embedding components, you can minimize parasitic effects, improve signal integrity, and even enhance thermal management. But the key question remains: does the ROI of embedded components justify the added manufacturing complexity? Let’s dive into the cost factors to find out.

Breaking Down PCB Manufacturing Costs: Embedded vs. SMT

Understanding the cost structure of PCB manufacturing is critical when deciding between embedded components and traditional SMT. Let’s break down the key cost drivers and compare the two approaches.

1. Material Costs

For SMT, material costs are straightforward. You purchase discrete components and the PCB substrate separately, and the assembly process adds them together. Embedded components, however, often require specialized materials, such as prepregs or laminates compatible with embedding processes. These materials can increase the upfront cost by 10-20% compared to standard FR-4 boards, depending on the complexity and volume of production.

However, embedding can reduce the number of components needed on the surface, potentially lowering the bill of materials (BOM) cost for high-density designs. For instance, embedding a 10 nF capacitor directly into the PCB can eliminate the need for a surface-mounted part, saving both space and component cost.

2. Manufacturing Complexity and Equipment

Embedding components adds steps to the manufacturing process, such as precise drilling, component placement within layers, and additional lamination cycles. This complexity often requires advanced equipment and skilled labor, which can increase production costs by 15-30% compared to SMT, especially for low-volume runs. On the other hand, SMT assembly is a well-established process with widely available automation, making it more cost-effective for simpler designs or larger batches.

3. Assembly and Labor Costs

SMT assembly typically involves automated pick-and-place machines, which are fast and efficient for surface components. Embedding, however, may require manual intervention or specialized machinery to ensure components are placed accurately within the board layers. This can drive labor costs higher, particularly for prototypes or small-scale projects where automation isn’t fully utilized.

Embedded Component Cost Analysis: Hidden Savings

While the upfront costs of embedded components may seem higher, a deeper cost analysis reveals potential savings that improve the ROI over time. Here are some key areas where embedding can reduce expenses.

1. Reduced Board Size and Layer Count

By embedding components, you can significantly shrink the size of your PCB. Smaller boards mean less material usage and, often, fewer layers, which directly cuts down on manufacturing costs. For example, a design that would typically require a 6-layer board with SMT might be reduced to a 4-layer board with embedded capacitors and resistors, saving up to 25% on material costs for large production runs.

2. Improved Reliability and Lower Failure Rates

Embedded components are protected within the PCB substrate, making them less susceptible to mechanical stress, vibration, or environmental factors like humidity. This can reduce failure rates by as much as 30% in harsh environments, leading to fewer warranty claims and repairs. For industries like automotive or aerospace, where reliability is non-negotiable, this translates into substantial long-term savings.

3. Enhanced Performance and Signal Integrity

Embedding components, especially decoupling capacitors, closer to the ICs they support can reduce parasitic inductance and improve signal integrity. For high-speed designs, this can mean a reduction in noise levels by up to 20 dB, ensuring better performance without the need for additional external components. While this doesn’t directly cut costs, it can prevent expensive redesigns or troubleshooting down the line.

ROI of Embedded Components: When Does It Pay Off?

Calculating the ROI of embedded components involves weighing the initial investment against long-term benefits. Here are the scenarios where embedding offers the best financial returns.

1. High-Volume Production

For large-scale production, the higher initial setup costs of embedding are offset by savings in material usage and assembly time. If you’re producing 10,000 units or more, the per-unit cost of embedding can drop significantly, often by 10-15% compared to SMT, due to economies of scale.

2. Miniaturized or High-Density Designs

In applications where space is at a premium, such as wearables or IoT devices, embedding components can eliminate the need for larger boards or additional modules. This not only reduces costs but also allows for more compact, marketable products. For instance, a smartwatch design using embedded passives might save 30% in board area, translating to lower production costs and a sleeker product.

3. Mission-Critical Applications

In industries where downtime or failure is extremely costly, such as medical or defense, the improved reliability of embedded components can justify the higher upfront costs. The ROI here isn’t just financial—it’s also about maintaining trust and safety standards that are critical to the end user.

Cost Comparison: SMT vs. Embedded Components

To provide a clearer picture, let’s compare the costs of SMT and embedded components for a hypothetical PCB design. Assume we’re designing a board for a consumer electronics device with a production run of 5,000 units.

- SMT Approach:

- Material Cost (including discrete components): $5 per board

- Assembly Cost: $3 per board

- Total Cost per Board: $8

- Total Cost for 5,000 Units: $40,000

- Embedded Approach:

- Material Cost (specialized substrate): $6 per board

- Assembly Cost (including embedding process): $4 per board

- Total Cost per Board: $10

- Total Cost for 5,000 Units: $50,000

At first glance, SMT appears cheaper by $10,000. However, if embedding reduces the board size and cuts the layer count from 6 to 4, the material cost might drop by $1.50 per board, saving $7,500 across 5,000 units. Additionally, if embedding improves reliability and reduces failure rates by 20%, you could save on returns and repairs, potentially another $2,000-$3,000. Suddenly, the cost gap narrows, and for larger runs or more complex designs, embedding could even become cheaper overall.

PCB Cost Optimization: Tips for Balancing Cost and Performance

Whether you choose embedded components or stick with SMT, optimizing PCB costs is essential for staying competitive. Here are some practical strategies to keep expenses in check while maximizing performance.

1. Design for Manufacturability (DFM)

Work closely with your manufacturing partner to ensure your design aligns with their capabilities. For embedded components, this means selecting parts that are compatible with their embedding process and avoiding overly complex layouts that increase production time. A well-thought-out DFM approach can reduce costs by up to 20% by minimizing errors and rework.

2. Evaluate Production Volume Early

As discussed earlier, embedded components often make more financial sense at higher volumes. Analyze your production needs upfront to determine whether the initial investment in embedding will pay off over time. For small runs or prototypes, SMT might be the safer, cheaper bet.

3. Leverage Simulation Tools

Use simulation software to test signal integrity and thermal performance before committing to a design. For embedded components, this can help you place parts optimally within the board to maximize performance benefits, avoiding costly redesigns. Simulations can predict issues like impedance mismatches (e.g., ensuring a 50-ohm trace for high-speed signals) before they become expensive problems.

4. Balance Cost with Application Needs

Not every design needs embedded components. For simpler circuits or cost-sensitive consumer products, SMT might suffice. Reserve embedding for applications where miniaturization, reliability, or performance gains are critical to the product’s success.

Challenges and Limitations of Embedded Components

While the benefits are clear, embedded components aren’t without challenges. It’s important to understand these limitations to avoid unexpected costs or delays.

1. Higher Initial Investment

As mentioned, the upfront costs for materials, equipment, and setup are higher for embedding. For small businesses or startups with limited budgets, this can be a barrier, especially if production volumes are low.

2. Limited Component Availability

Not all components can be embedded. Active components like microcontrollers or larger ICs often still need to be surface-mounted, and only certain passives are available in embeddable formats. This can limit design flexibility and force a hybrid approach, combining SMT and embedding, which may increase complexity.

3. Repair and Rework Challenges

Once embedded, components are nearly impossible to access for repairs or replacements. If a design flaw or component failure occurs, the entire board may need to be scrapped, increasing waste and costs. This is less of an issue with SMT, where components can be desoldered and replaced relatively easily.

Conclusion: Is Embedding the Right Choice for Your PCB Design?

Deciding between embedded components and traditional SMT in PCB manufacturing comes down to a careful balance of cost, performance, and application needs. While embedding often involves higher upfront costs, the long-term ROI can be impressive, especially for high-volume production, miniaturized designs, or mission-critical applications. Savings from reduced board size, improved reliability, and better performance can offset the initial investment, making it a cost-effective choice in the right scenarios.

At ALLPCB, we’re committed to helping you optimize your PCB designs for both cost and quality. Whether you’re exploring embedded components or sticking with SMT, our team can guide you through the process to ensure the best outcomes for your project. By focusing on PCB cost optimization and leveraging advanced manufacturing techniques, you can stay ahead in the competitive world of electronics design.

Take the time to analyze your specific needs, production volumes, and performance goals. With the right approach, embedding could be the key to unlocking significant savings and superior designs in your next PCB project.

ALLPCB

ALLPCB