In the fast-paced world of PCB manufacturing, ensuring quality and precision is critical. One of the most effective ways to achieve this is through Automated Optical Inspection (AOI) systems. But how do you program an AOI machine to deliver accurate results? In this guide, we’ll dive into the AOI machine programming method, exploring the use of an AOI automated teaching tool, the process for AOI code, and the steps for generating inspection instructions. Whether you’re new to AOI or looking to optimize your setup, this blog offers practical insights to enhance your inspection process.

What Is AOI Machine Programming and Why Does It Matter?

AOI machine programming is the process of setting up an Automated Optical Inspection system to detect defects on printed circuit boards (PCBs) during manufacturing. This involves creating a set of instructions or code that tells the machine what to look for—such as missing components, solder defects, or misalignments—and how to interpret the data it captures. With the right programming, an AOI system can save time, reduce costs, and ensure high-quality output by catching errors early in the production line.

The importance of effective programming cannot be overstated. Poorly programmed AOI machines may miss critical defects or generate false positives, leading to wasted resources and potential failures in the final product. By mastering AOI programming, manufacturers can achieve consistent results, improve efficiency, and maintain customer satisfaction.

Key Components of AOI Machine Programming

Before diving into the programming methods, let’s break down the essential components that form the foundation of an AOI system’s operation. Understanding these elements will help in crafting effective inspection instructions.

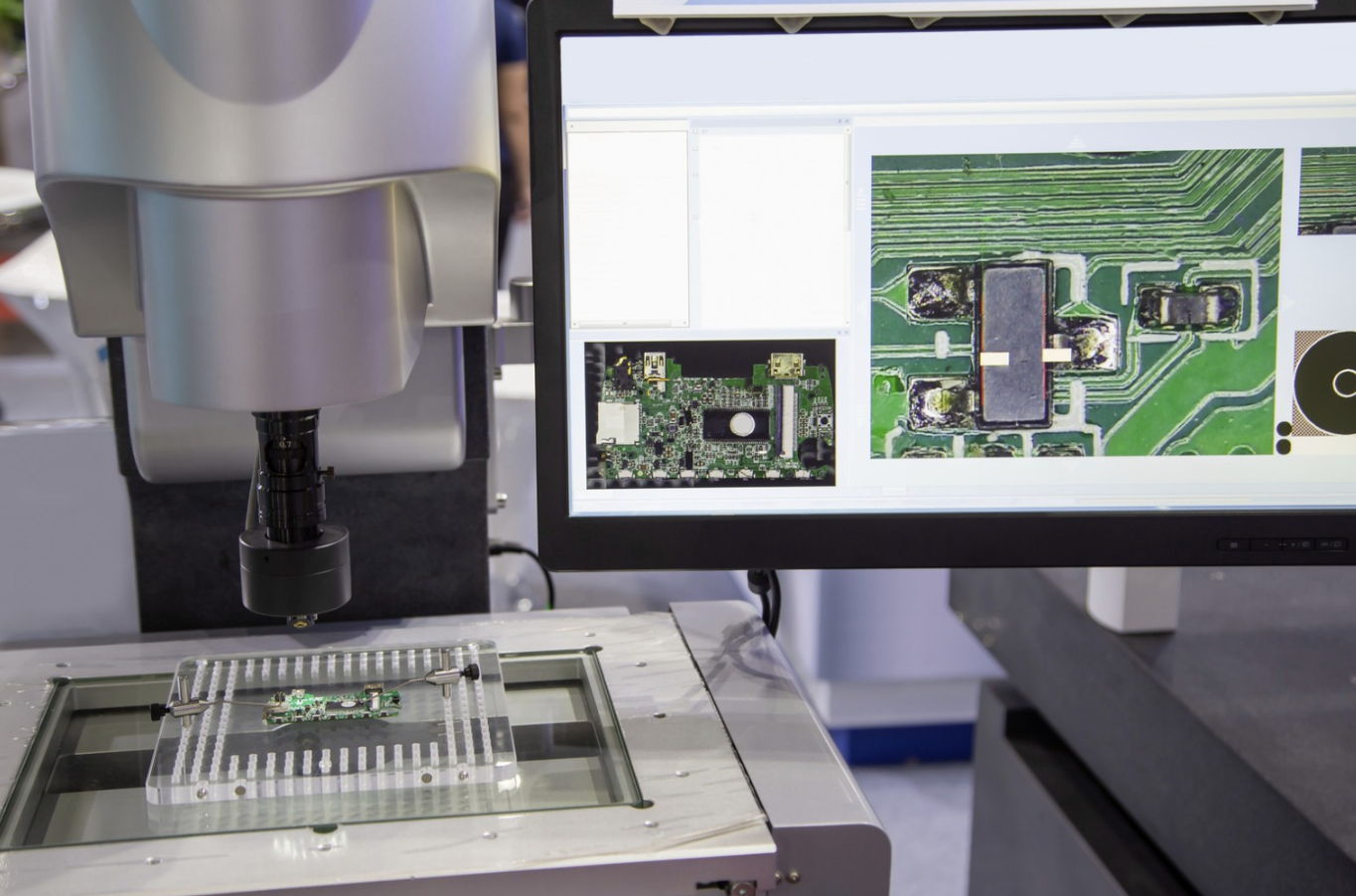

- Camera and Imaging System: The core of an AOI machine, responsible for capturing high-resolution images of the PCB. Programming must account for lighting conditions and camera angles to ensure clear visuals.

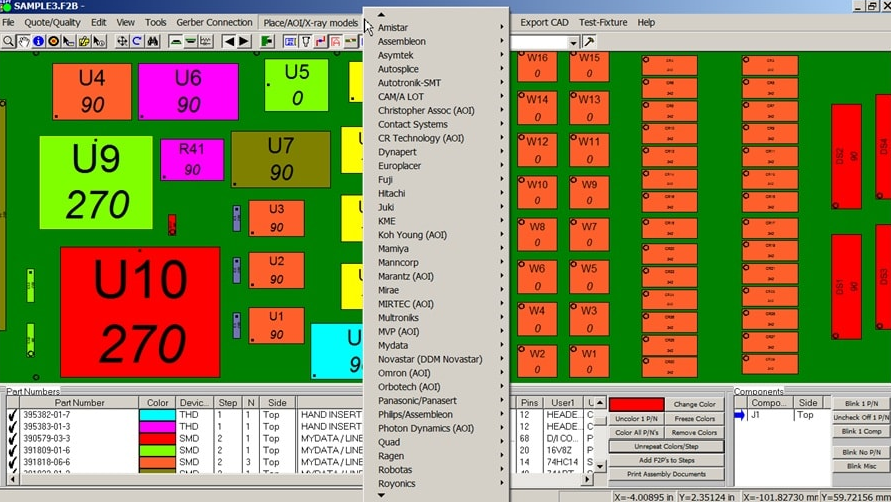

- Software Interface: This is where the programming happens. The software allows users to define inspection parameters, set defect criteria, and review results.

- Inspection Algorithms: These are the rules or logic programmed into the system to identify defects. Algorithms compare captured images against a reference (like a golden board or CAD data).

- Data Output: After inspection, the machine generates reports or alerts. Programming determines how results are displayed and prioritized for operators.

Step-by-Step AOI Machine Programming Method

Programming an AOI machine is a structured process that requires attention to detail. Below, we outline a practical method to ensure accurate and efficient inspections, incorporating the use of automated teaching tools and code generation.

Step 1: Prepare the Reference Data

The first step in AOI programming is to establish a baseline for comparison. This is often done using a “golden board”—a defect-free PCB that serves as the standard—or by importing CAD (Computer-Aided Design) data. The reference data tells the AOI system what a perfect board looks like, including component placement, solder joints, and other features.

Ensure that the reference data is accurate and up-to-date. For example, if your PCB design has components with a placement tolerance of ±0.1 mm, this value must be reflected in the programming to avoid false defect calls.

Step 2: Use an AOI Automated Teaching Tool

An AOI automated teaching tool simplifies the programming process by guiding users through setup with minimal manual input. These tools often come integrated into the AOI software and use machine learning or predefined templates to teach the system what to inspect.

For instance, the teaching tool might automatically detect component outlines and solder joint patterns on a sample PCB. It then generates initial inspection parameters, such as brightness thresholds or defect size limits (e.g., detecting solder bridges larger than 0.05 mm). Users can fine-tune these settings to match specific requirements, saving significant time compared to manual programming.

Automated teaching tools are especially useful for complex boards with hundreds of components, as they reduce human error and ensure consistency across multiple production runs.

Step 3: Define Inspection Parameters and Defect Criteria

Once the reference data is loaded and the teaching tool has provided a starting point, it’s time to set specific inspection parameters. This includes defining what constitutes a defect and setting thresholds for acceptable variations.

For example:

- Component Placement: Set a tolerance of ±0.2 mm for component positioning. Anything beyond this range is flagged as a defect.

- Solder Joints: Program the system to detect insufficient solder if the fillet height is below 0.3 mm.

- Foreign Objects: Instruct the machine to flag any unexpected shapes or shadows larger than 0.1 mm2 as potential contaminants.

These parameters must align with industry standards like IPC-A-610, which defines acceptability criteria for electronic assemblies, ensuring your AOI system delivers reliable results.

Step 4: Develop the Process for AOI Code

The process for AOI code involves translating the defined parameters into a format the machine can execute. This code acts as a set of instructions for the AOI system, guiding how it captures images, processes data, and identifies defects.

Modern AOI systems often use graphical interfaces where users input parameters through dropdowns or sliders, automatically generating the underlying code. However, for advanced customization, some systems allow direct scripting using languages like Python or proprietary formats. The code specifies details such as:

- Camera scan speed (e.g., 50 mm/s for high-resolution imaging).

- Lighting intensity (e.g., 80% for optimal contrast on reflective surfaces).

- Inspection zones (e.g., focusing only on high-density component areas).

Testing the code on a small batch of boards is crucial to ensure it performs as expected before full-scale deployment.

Step 5: Generate Inspection Instructions

The final step is generating inspection instructions that the AOI machine follows during operation. These instructions are essentially the compiled output of your programming efforts, combining reference data, parameters, and code into a cohesive workflow.

Inspection instructions detail the sequence of actions, such as:

- Load the PCB onto the inspection platform.

- Adjust camera and lighting based on programmed settings.

- Scan predefined areas of the board at specified resolutions (e.g., 5 microns per pixel for fine-pitch components).

- Compare captured images against the reference, applying defect criteria.

- Output results, flagging defects with coordinates (e.g., defect at X=10 mm, Y=15 mm).

Once generated, these instructions are saved as a “recipe” or program file in the AOI system, ready to be reused for identical board designs.

Best Practices for Optimizing AOI Programming

To get the most out of your AOI machine programming, consider these best practices that enhance accuracy and efficiency.

Regularly Update Reference Data

PCB designs evolve, and so should your reference data. If a component supplier changes a part’s dimensions by even 0.05 mm, update the golden board or CAD file to reflect this. Failing to do so can lead to false positives or missed defects.

Minimize False Alarms

False alarms slow down production as operators must manually verify flagged issues. Fine-tune defect thresholds and use automated teaching tools to train the system on real-world variations, reducing unnecessary alerts by up to 30% in some cases.

Integrate with Production Lines

Program your AOI system to communicate with other equipment, like pick-and-place machines or reflow ovens. For instance, if the AOI detects a recurring defect at a specific solder joint, it can send feedback to adjust the upstream soldering temperature by 5°C to prevent future issues.

Test and Validate

After programming, run the AOI system on a test batch of 50-100 boards. Analyze the defect detection rate and false positive rate. Aim for a detection accuracy of at least 95% before scaling up to full production.

Benefits of Mastering AOI Machine Programming

Investing time in effective AOI programming yields significant advantages for PCB manufacturers:

- Higher Quality: Detect defects as small as 0.02 mm, ensuring only flawless boards reach customers.

- Cost Savings: Reduce manual inspection labor by up to 80% with automated systems.

- Faster Production: Cut inspection times from hours to minutes, with some systems scanning a board in under 30 seconds.

- Traceability: Detailed inspection reports provide data for root cause analysis, improving future designs.

Challenges in AOI Programming and How to Overcome Them

While AOI programming offers many benefits, it comes with challenges. Here are common issues and solutions:

- Complex Board Designs: High-density boards with tiny components (e.g., 0201 packages) can be hard to inspect. Solution: Use high-resolution cameras (10 microns per pixel or better) and adjust lighting for clarity.

- Software Learning Curve: Some AOI systems have complex interfaces. Solution: Leverage automated teaching tools and manufacturer-provided training resources.

- Evolving Standards: Defect criteria change with new industry standards. Solution: Stay updated on guidelines like IPC-A-610 and revise programming annually.

Conclusion: Elevate Your PCB Inspection with AOI Programming

Mastering the AOI machine programming method is a game-changer for PCB manufacturing. By utilizing an AOI automated teaching tool, following a streamlined process for AOI code, and carefully generating inspection instructions, manufacturers can achieve unparalleled precision and efficiency. The steps outlined—preparing reference data, setting parameters, coding, and testing—provide a clear path to success.

At ALLPCB, we’re committed to supporting your journey in PCB production with cutting-edge solutions and expert guidance. Implement these programming techniques to enhance your AOI system’s performance and deliver top-quality boards every time.

ALLPCB

ALLPCB