In today’s fast-paced electronics industry, efficiency and reliability are key to staying competitive. If you’re looking for a way to simplify your production while ensuring high-quality results, turnkey PCB manufacturing services offer a complete solution. These services handle everything from design to assembly, saving you time and reducing costs. In this blog, we’ll explore how turnkey PCB manufacturing, full turnkey PCB solutions, and one-stop PCB services can streamline your production process, diving deep into the benefits, processes, and practical applications for engineers and businesses.

What Are Turnkey PCB Manufacturing Services?

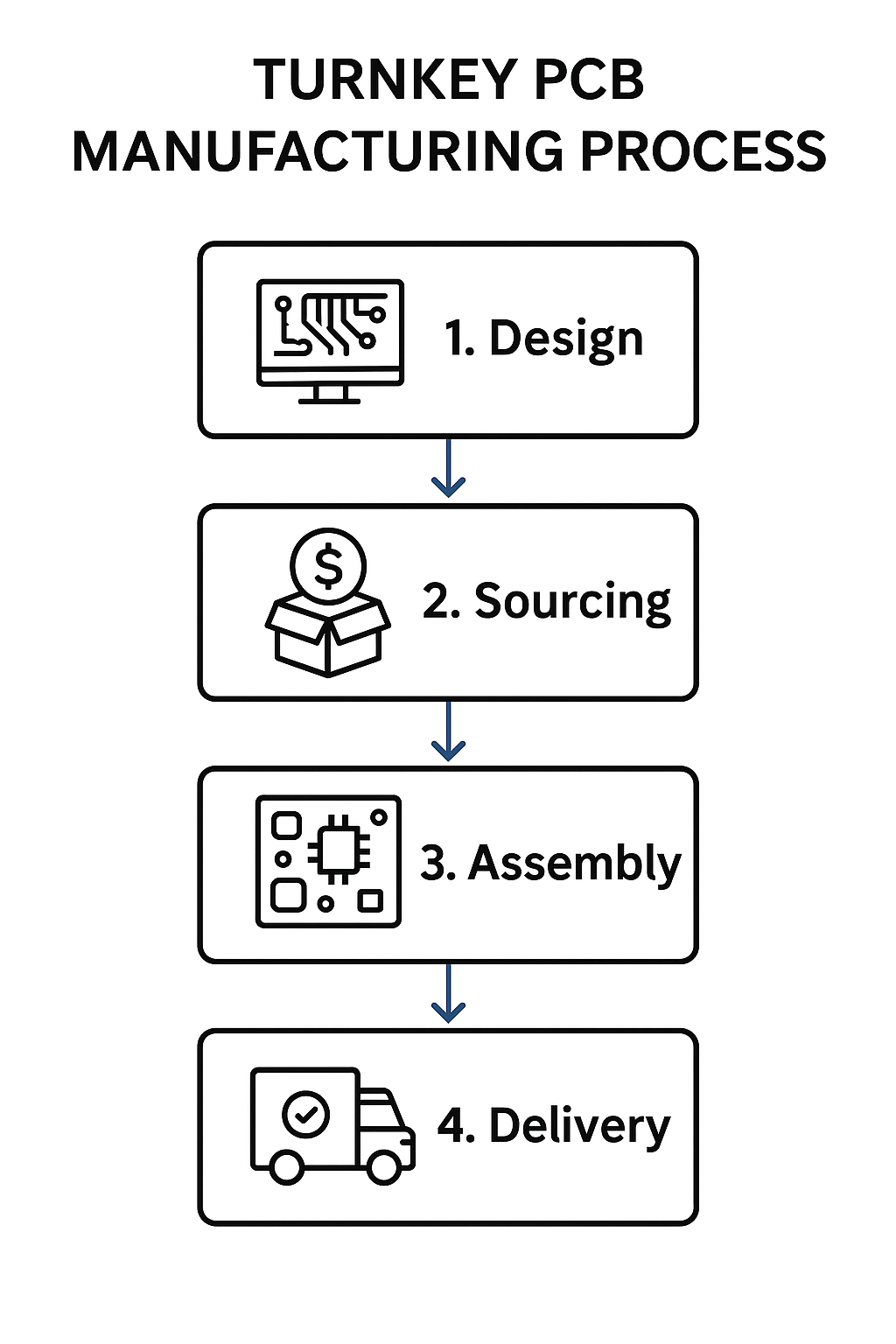

Turnkey PCB manufacturing refers to a comprehensive service where a single provider manages every aspect of printed circuit board (PCB) production. This includes PCB design, component sourcing, fabrication, assembly, and even testing. Unlike traditional methods where you might need to coordinate with multiple vendors, a complete PCB solution under the turnkey model means you hand over the project and receive a finished product ready for use.

The primary goal of full turnkey PCB services is to simplify the production process. By consolidating all steps under one roof, you avoid the hassle of managing different suppliers, which often leads to delays or miscommunication. Whether you’re a startup developing a prototype or a large company producing high-volume batches, these services adapt to your needs, ensuring faster time-to-market and consistent quality.

Key Benefits of Turnkey PCB Manufacturing

Opting for turnkey PCB manufacturing brings several advantages that directly impact your production efficiency and bottom line. Let’s break down the core benefits:

1. Simplified Project Management

With a one-stop PCB service, you deal with a single point of contact for the entire project. This eliminates the need to juggle multiple vendors for design, sourcing, and assembly. For instance, instead of spending weeks negotiating with a component supplier and a separate assembly house, a turnkey provider coordinates everything, reducing your workload and minimizing errors.

2. Cost Efficiency

Turnkey services often lower overall costs by leveraging bulk purchasing power for PCB component sourcing. Providers can negotiate better prices for parts, passing the savings on to you. Additionally, consolidating services reduces shipping and handling expenses that come with working with multiple vendors. For example, a project requiring 10,000 resistors and capacitors might see a 15-20% cost reduction through a turnkey provider’s sourcing network.

3. Faster Time-to-Market

Speed is critical in electronics manufacturing. Full turnkey PCB solutions streamline workflows by integrating design, fabrication, and PCB assembly into a seamless process. This can shave weeks off your production timeline. Imagine a scenario where a prototype needs to be ready for testing in 30 days—turnkey services can often meet such tight deadlines by optimizing each stage internally.

4. Quality Assurance

A complete PCB solution ensures consistency across all production stages. Since the same provider oversees everything, they maintain strict quality control from component selection to final assembly. Many turnkey providers adhere to standards like ISO 9001:2015, guaranteeing that your boards meet industry benchmarks for reliability, such as maintaining impedance values within ±10% for high-speed signal integrity (typically around 50-100 ohms for standard designs).

How Turnkey PCB Manufacturing Streamlines Production

The turnkey approach is designed to remove bottlenecks and inefficiencies from the production cycle. Here’s how each stage contributes to a smoother process:

1. Integrated Design and Prototyping

The journey often begins with PCB design. Turnkey providers work closely with your team to refine schematics and layouts, ensuring manufacturability. They use advanced software to simulate performance, identifying issues like signal crosstalk or thermal hotspots before fabrication. For high-speed designs, maintaining controlled impedance (e.g., 50 ohms for USB or HDMI signals) is critical, and turnkey services optimize layer stack-ups to achieve this.

2. Efficient PCB Component Sourcing

Component sourcing can be a major headache, especially with global supply chain disruptions. Turnkey providers maintain extensive networks of trusted suppliers, ensuring access to parts even during shortages. They also verify component authenticity, reducing the risk of counterfeit parts that could fail under operational stress (e.g., capacitors rated for 16V failing at 12V due to poor quality).

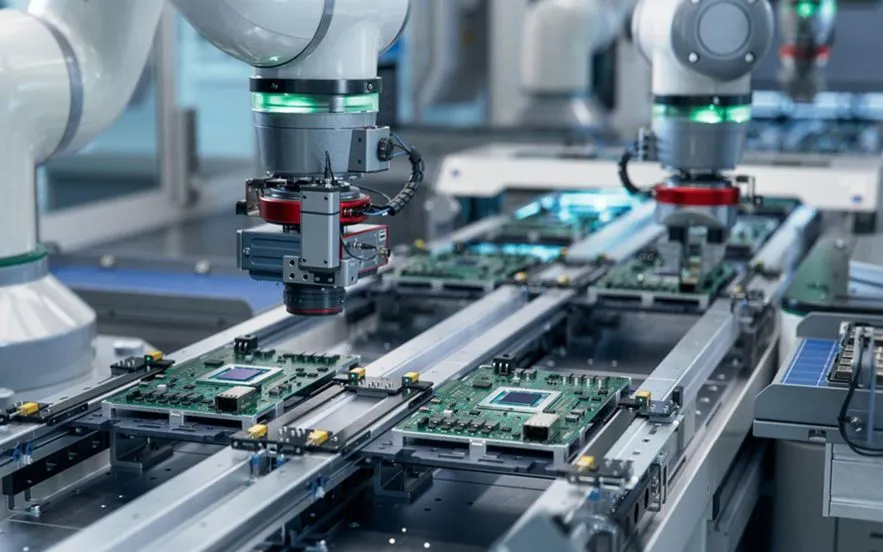

3. Seamless PCB Assembly

Once components are sourced and the PCB is fabricated, assembly begins. Turnkey PCB assembly includes surface-mount technology (SMT) and through-hole techniques, depending on your design. Automated pick-and-place machines ensure precision, placing components at speeds of up to 100,000 parts per hour for high-volume runs. This minimizes human error, ensuring consistent soldering and placement accuracy within 0.01mm tolerances.

4. Comprehensive Testing and Quality Checks

After assembly, turnkey providers conduct rigorous testing to validate functionality. This includes automated optical inspection (AOI) for soldering defects and in-circuit testing (ICT) to verify electrical performance. For critical applications like medical devices, they might perform signal integrity tests to ensure data transmission rates (e.g., 5 Gbps for PCIe lanes) meet specifications. Only boards that pass these checks move to final packaging.

Who Can Benefit from Full Turnkey PCB Solutions?

Turnkey PCB manufacturing is versatile, catering to a wide range of industries and project scales. Here are some key groups that stand to gain the most:

1. Startups and Small Businesses

For smaller companies with limited resources, managing a PCB project can be overwhelming. Turnkey services allow them to focus on product innovation while the provider handles production logistics. A startup developing an IoT device, for example, can rely on turnkey solutions to produce 100-500 units for market testing without investing in in-house expertise.

2. Large Enterprises with High-Volume Needs

Larger firms benefit from the scalability of turnkey services. Whether producing 10,000 or 100,000 units, these providers optimize supply chains and production schedules to meet demand. They also offer flexibility to adjust orders mid-cycle, which is crucial for industries like automotive, where designs might require last-minute tweaks to meet safety standards.

3. Engineers and R&D Teams

For engineers working on prototypes, turnkey PCB manufacturing accelerates the design-to-test cycle. Quick turnaround times—often under 2 weeks for prototypes—mean faster iterations. If a design requires specific RF performance (e.g., signal loss below 0.5 dB at 2.4 GHz for Wi-Fi modules), turnkey providers can source materials like high-frequency laminates to meet those specs.

Choosing the Right Turnkey PCB Manufacturing Partner

Not all turnkey providers are created equal. To ensure a smooth production process, consider these factors when selecting a partner:

- Experience and Expertise: Look for a provider with a proven track record in your industry. If you’re in aerospace, for instance, ensure they understand stringent requirements like MIL-PRF-31032 standards.

- Scalability: Confirm they can handle your volume needs, whether it’s a small batch of 10 boards or a run of 50,000.

- Transparency: A reliable partner provides clear updates on timelines, costs, and potential issues like component lead times (often 4-12 weeks for specialized ICs).

- Quality Certifications: Check for certifications like ISO 9001 or IPC-A-610, which indicate adherence to industry best practices.

Common Challenges in PCB Production and How Turnkey Solves Them

Even with the best planning, PCB production can face hurdles. Turnkey services are built to address these challenges head-on:

1. Supply Chain Delays

Component shortages can stall projects for months. Turnkey providers mitigate this by maintaining alternative sourcing options and inventory buffers, ensuring production stays on track even if a specific 3.3V regulator chip has a 20-week lead time.

2. Design Errors

Mistakes in PCB layout, like incorrect trace widths for high-current paths (e.g., 0.5mm traces unable to handle 2A), can lead to costly rework. Turnkey providers often include design-for-manufacturing (DFM) reviews to catch such issues early.

3. Communication Gaps

Working with multiple vendors increases the risk of miscommunication. A one-stop PCB service eliminates this by centralizing all interactions, ensuring your requirements—like specific soldering temperatures of 260°C for lead-free processes—are clearly understood and implemented.

Future Trends in Turnkey PCB Manufacturing

The turnkey PCB industry is evolving with technology and market demands. Here are some trends shaping its future:

- Automation and AI: Advanced automation is reducing assembly times, with AI-driven systems optimizing component placement for thermal and electrical performance.

- Sustainability: Providers are adopting eco-friendly materials and processes, like lead-free soldering and recyclable substrates, to meet environmental regulations.

- Miniaturization: As devices shrink, turnkey services are adapting to handle micro-BGA components and high-density interconnect (HDI) boards with via-in-pad designs for space-constrained applications.

Conclusion: Why Turnkey PCB Manufacturing Is the Way Forward

Turnkey PCB manufacturing services offer a powerful way to streamline your production process, from design to delivery. By integrating PCB component sourcing, fabrication, and assembly into a complete PCB solution, these services save time, reduce costs, and ensure high-quality outcomes. Whether you’re an engineer refining a prototype or a business scaling production, full turnkey PCB solutions provide the efficiency and reliability you need to succeed in a competitive market.

With one-stop PCB services, you can focus on innovation while leaving the complexities of manufacturing to experts. The result? Faster turnarounds, fewer headaches, and products that meet the highest standards. Embrace turnkey PCB manufacturing today and transform the way you bring your electronics projects to life.

ALLPCB

ALLPCB