In the fast-evolving world of electronics, printed circuit boards (PCBs) are at the heart of innovation. One of the most exciting advancements shaping the industry is embedded component technology. But what exactly does this mean for the future of PCB design, and how is it transforming industries like aerospace and medical devices? At its core, embedded component technology involves integrating components directly into the layers of a PCB, enhancing performance, reducing size, and improving reliability. In this blog, we’ll dive deep into the potential of advanced PCB technology, focusing on innovative PCB applications and the role of embedded components in aerospace and medical devices.

Whether you’re an engineer, designer, or tech enthusiast, this post will explore how these advancements are paving the way for smarter, more efficient electronics. Let’s uncover the future of PCB design and the groundbreaking possibilities that lie ahead.

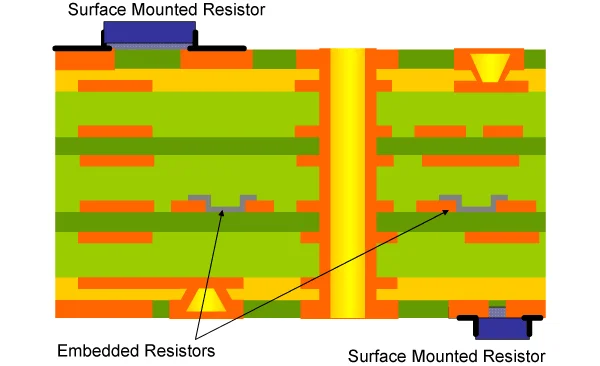

What Is Embedded Component Technology in PCBs?

Embedded component technology refers to the process of integrating active and passive components—such as resistors, capacitors, and even microchips—directly into the internal layers of a PCB. Unlike traditional surface-mounted components, these are buried within the board, creating a more compact and efficient design. This approach minimizes the need for external connections, reduces signal interference, and enhances overall durability.

The benefits are clear: smaller footprints for devices, improved electrical performance with shorter signal paths, and better thermal management. For instance, signal integrity can be significantly enhanced by reducing trace lengths, often achieving impedance values as low as 50 ohms for high-speed applications. This technology is a game-changer for industries requiring high reliability and precision, setting the stage for the future of PCB design.

Why Embedded Components Are Shaping the Future of PCB Design

The future of PCB design is being redefined by the push for miniaturization, efficiency, and sustainability. Embedded components are at the forefront of this transformation. By integrating components into the board itself, manufacturers can achieve higher component density, which is critical for modern electronics where space is at a premium. This also reduces the number of solder joints, lowering the risk of failure and improving reliability—a key factor in mission-critical applications.

Moreover, this technology supports the growing demand for high-speed data transmission. With embedded components, signal speeds can reach up to 10 Gbps or higher in some designs, thanks to reduced parasitic effects. As industries continue to demand smarter and smaller devices, embedded component technology will play a pivotal role in meeting these needs, making it a cornerstone of innovative PCB applications.

Key Benefits Driving Adoption

- Space Efficiency: Reduces board size by up to 30% in some cases, ideal for compact devices.

- Enhanced Performance: Shorter interconnects improve signal integrity and reduce latency.

- Improved Reliability: Fewer external connections mean less risk of mechanical failure.

- Cost Efficiency: Streamlined manufacturing processes can lower production costs over time.

Embedded Components in Aerospace: Powering the Skies

The aerospace industry demands electronics that can withstand extreme conditions while maintaining flawless performance. Embedded components in aerospace applications are revolutionizing how systems like navigation, communication, and control are designed. By integrating components directly into PCBs, aerospace engineers can create lighter, more compact systems that are critical for aircraft and spacecraft where every gram counts.

For example, in satellite systems, embedded technology helps reduce the size of control boards while ensuring they can handle high-frequency signals, often exceeding 1 GHz. This not only saves space but also improves resistance to vibration and thermal stress—key factors in the harsh environment of space. Additionally, the reduced number of external connections enhances reliability, which is vital for systems that cannot be easily repaired once deployed.

Advanced PCB technology with embedded components also supports the development of next-generation avionics. These systems require high-speed data processing and robust designs to manage complex tasks like real-time flight monitoring. With embedded components, signal integrity is maintained even under high electromagnetic interference, ensuring safety and precision in flight operations.

Embedded Components in Medical Devices: Advancing Healthcare

In the medical field, precision and reliability are non-negotiable. Embedded components in medical devices are enabling the creation of smaller, more efficient tools that are transforming patient care. From wearable health monitors to implantable devices like pacemakers, this technology is making it possible to pack advanced functionality into tiny form factors.

Consider wearable glucose monitors, which rely on compact PCBs to process and transmit data in real time. Embedded components allow these devices to maintain a low profile while achieving power efficiency, often operating on batteries that last weeks. In implantable devices, the technology ensures minimal signal loss and high reliability, with impedance values carefully controlled to match biological systems, sometimes as precise as 75 ohms for specific sensor applications.

Furthermore, embedded components contribute to the sterilization and durability of medical equipment. By reducing exposed connections, these designs are less prone to damage during cleaning processes, ensuring longevity and consistent performance. As healthcare continues to embrace digital solutions, the role of advanced PCB technology in medical innovation will only grow.

Innovative PCB Applications: Beyond Aerospace and Medical

While aerospace and medical applications are leading the charge, the impact of embedded component technology extends far beyond these fields. Innovative PCB applications are emerging in various industries, driven by the need for smarter, more connected solutions. Let’s explore a few areas where this technology is making waves.

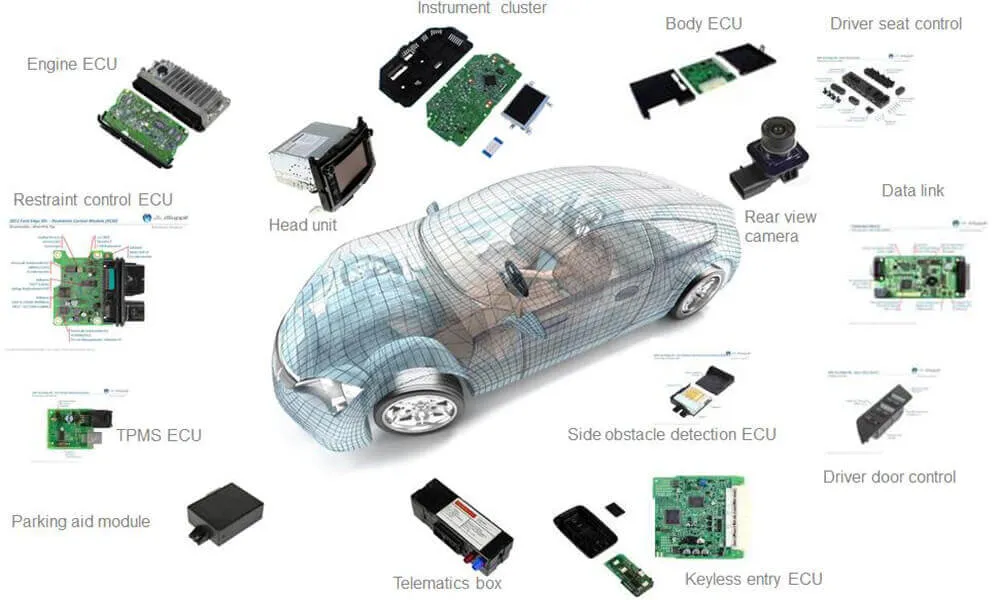

Automotive Electronics

The automotive sector is undergoing a digital transformation with the rise of electric vehicles (EVs) and autonomous driving systems. Embedded components help create compact control units that manage everything from battery systems to sensor arrays. These designs improve thermal performance and reduce electromagnetic interference, ensuring reliable operation in the demanding conditions of a vehicle.

Consumer Electronics

From smartphones to smartwatches, consumer electronics are becoming smaller and more powerful. Embedded components enable manufacturers to pack more features into limited spaces, supporting high-speed data transfer rates of up to 5 Gbps in some devices. This technology is key to meeting consumer demand for sleek, multifunctional gadgets.

Industrial IoT

The Industrial Internet of Things (IoT) relies on robust, compact electronics to monitor and control machinery. Embedded components in PCBs enhance the durability of these systems, allowing them to operate in harsh environments with temperature ranges from -40°C to 85°C. This reliability is crucial for maintaining uptime in smart factories.

Challenges and Solutions in Adopting Embedded Component Technology

Despite its many advantages, integrating embedded components into PCBs comes with challenges. One major hurdle is the complexity of the manufacturing process. Embedding components requires precise layering and lamination techniques, often involving advanced equipment and skilled labor. This can initially increase production costs, though long-term savings are often realized through improved efficiency.

Another challenge is thermal management. With components buried within the board, heat dissipation can be trickier to manage. However, advancements in materials, such as high-thermal-conductivity substrates with values up to 3 W/mK, are helping address this issue. Additionally, design software now offers simulation tools to predict and mitigate thermal risks before production.

Testing and inspection also pose difficulties, as embedded components are not easily accessible. To overcome this, manufacturers are adopting non-destructive testing methods like X-ray imaging to ensure quality without damaging the board. These solutions are paving the way for wider adoption of this transformative technology.

The Road Ahead: What’s Next for Advanced PCB Technology?

Looking to the future, the potential of embedded component technology is limitless. As design tools and manufacturing processes continue to evolve, we can expect even greater integration of components, including advanced sensors and microprocessors, directly into PCBs. This will further blur the lines between hardware and software, enabling truly intelligent systems.

Sustainability will also play a larger role in the future of PCB design. With embedded components reducing material usage and improving energy efficiency, this technology aligns with global efforts to create eco-friendly electronics. Innovations like biodegradable substrates and recyclable materials are on the horizon, promising a greener approach to manufacturing.

Finally, the rise of 5G, artificial intelligence, and the Internet of Things will drive demand for high-performance PCBs. Embedded components will be critical in supporting these technologies, offering the speed, reliability, and compactness needed for next-generation applications. The industry is poised for a revolution, and advanced PCB technology will be at its core.

Conclusion: Embracing the Future with Embedded Component Technology

The future of PCBs is bright, and embedded component technology is leading the charge. From enabling life-saving medical devices to powering the next generation of aerospace systems, this advancement is unlocking new possibilities across industries. By embracing advanced PCB technology, engineers and designers can create smaller, faster, and more reliable electronics that meet the demands of a connected world.

As we move forward, staying ahead of the curve means adopting innovative PCB applications and exploring the full potential of embedded components. Whether you’re working on cutting-edge aerospace projects or designing the latest consumer gadgets, this technology offers the tools to turn ideas into reality. The journey of PCB design is just beginning, and the possibilities are endless.

ALLPCB

ALLPCB