When designing LED PCBs, selecting the right solder mask is crucial for enhancing both light reflection and thermal performance. A well-chosen solder mask, such as a white solder mask, can significantly improve light output by reflecting more light, while also aiding in heat dissipation to ensure the longevity of LED components. In this comprehensive guide, we’ll dive deep into how solder masks impact LED PCB performance, focusing on optimizing light reflection and thermal management. Whether you're an engineer or a designer, you'll find practical insights on choosing the best solder mask for your LED applications using keywords like solder mask LED, white solder mask, light reflection PCB, thermal PCB solder mask, and solder mask and LED.

What Is a Solder Mask and Why Does It Matter for LED PCBs?

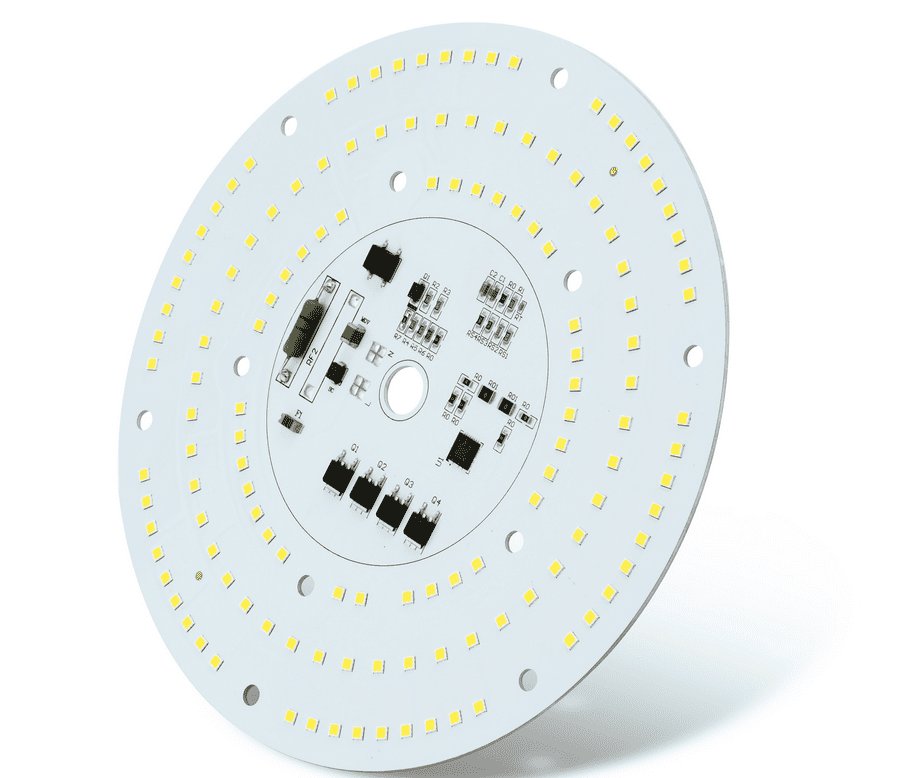

A solder mask is a protective layer applied to a printed circuit board (PCB) to prevent short circuits, protect copper traces from oxidation, and guide solder during assembly. For LED PCBs, the solder mask plays an additional role beyond protection—it directly influences light reflection and thermal performance. LED applications, such as lighting fixtures, automotive headlights, and display panels, require maximum light output and efficient heat dissipation to maintain performance and lifespan.

The choice of solder mask color and material can affect how much light is reflected off the PCB surface and how well heat is managed. For instance, a white solder mask is often preferred in LED designs because it reflects more light compared to traditional green or black masks, enhancing brightness. Additionally, certain solder mask formulations can contribute to better thermal conductivity, which is vital for preventing overheating in high-power LED setups.

The Role of Solder Mask in Light Reflection for LED PCBs

In LED applications, maximizing light output is a top priority. The solder mask’s color and finish significantly impact how much light is reflected off the PCB surface. A light reflection PCB design often incorporates a white solder mask because it can reflect up to 85-90% of visible light, compared to only 50-60% for green masks and even less for black masks. This increased reflectivity translates to brighter LED output, which is especially important in applications like commercial lighting or backlighting for displays.

White solder masks are formulated with materials that scatter and reflect light effectively. Some advanced masks even include reflective additives to boost performance further. However, not all white masks are equal—some may yellow over time due to UV exposure or high temperatures, reducing their reflective properties. When selecting a solder mask for LED projects, it’s essential to choose one with high UV resistance and stability to maintain consistent light reflection PCB performance over time.

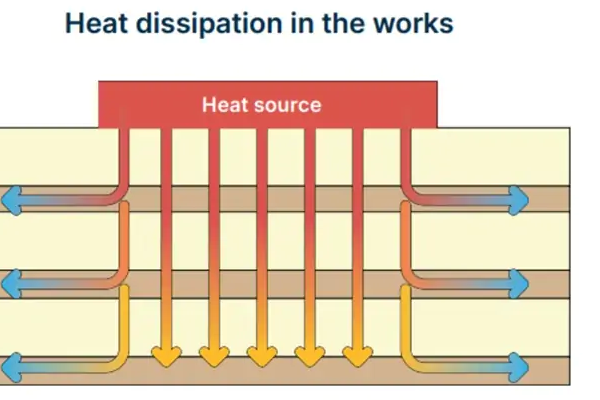

Thermal Performance: How Solder Mask Affects Heat Dissipation

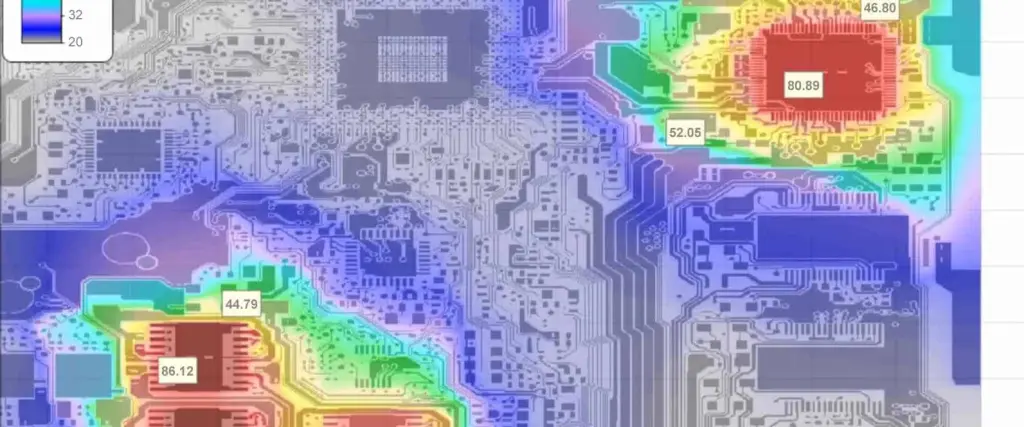

LEDs generate significant heat, especially in high-power applications. If this heat isn’t managed properly, it can reduce the lifespan of the LEDs and degrade performance. A thermal PCB solder mask plays a critical role in heat dissipation by acting as an insulating layer that can either trap heat or help transfer it away from critical components, depending on its composition.

Traditional solder masks have limited thermal conductivity, often in the range of 0.2-0.3 W/m·K, which can hinder heat dissipation. However, specialized solder masks designed for thermal management can offer improved conductivity, sometimes reaching up to 1.0 W/m·K or higher when combined with thermally conductive substrates. These masks help transfer heat from the LED components to the PCB’s heat sinks or metal core layers, maintaining optimal operating temperatures (typically below 85°C for most LEDs to avoid thermal runaway).

For LED PCBs, combining a white solder mask with thermal properties offers a dual benefit: enhanced light reflection and better heat management. This is particularly useful in compact designs where space for additional cooling solutions is limited. When designing for thermal performance, ensure the solder mask thickness is optimized—typically between 0.8 to 1.2 mils (20-30 micrometers)—to balance insulation and heat transfer.

Choosing the Right Solder Mask for LED Applications

Selecting the appropriate solder mask LED solution requires balancing light reflection, thermal performance, and durability. Here are key factors to consider:

1. Color and Reflectivity

As mentioned earlier, a white solder mask is ideal for maximizing light reflection in LED PCBs. Look for masks with high diffuse reflectance values (above 85%) to ensure optimal brightness. Be cautious of low-quality masks that may degrade under prolonged exposure to light or heat, as this can reduce reflectivity and affect the aesthetic of the final product.

2. Thermal Conductivity

For high-power LED designs, prioritize a thermal PCB solder mask with enhanced heat dissipation properties. Check the manufacturer’s specifications for thermal conductivity ratings and ensure compatibility with the PCB substrate, especially if using metal-core PCBs (MCPCBs) common in LED designs.

3. Durability and Environmental Resistance

LED PCBs are often exposed to harsh conditions, including high humidity, UV light, and temperature fluctuations. Choose a solder mask with excellent chemical resistance and stability to prevent cracking, peeling, or discoloration over time. A mask with a high glass transition temperature (Tg) of 140°C or above is recommended for thermal stability.

4. Application Method and Thickness

The method of applying the solder mask—such as liquid photoimageable (LPI) or dry film—can affect its performance. LPI masks are commonly used for LED PCBs due to their ability to achieve uniform thin layers, which are ideal for both light reflection and thermal management. Aim for a thickness that avoids excessive insulation while providing adequate protection.

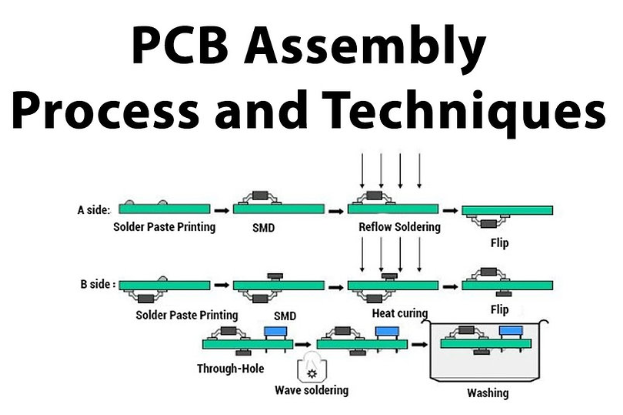

Types of Solder Masks for LED PCBs

There are several types of solder masks available, each with unique properties that can influence their suitability for solder mask and LED designs. Below are the most common types:

Liquid Photoimageable Solder Mask (LPI)

LPI is the most widely used solder mask for LED PCBs due to its precision and ability to form thin, uniform layers. It is applied as a liquid and cured using UV light, allowing for detailed patterns. LPI masks are available in white and other colors, with many formulations offering good reflectivity and moderate thermal performance.

Dry Film Solder Mask

Dry film masks are less common for LED applications but can be used in specific cases. They are applied as a solid sheet and offer excellent durability. However, they are thicker than LPI masks, which may impact thermal conductivity and light reflection.

Specialty Thermal Solder Masks

Some manufacturers offer specialty solder masks designed specifically for thermal management. These often incorporate fillers or additives to improve heat dissipation, making them ideal for high-power LED PCBs where overheating is a concern.

Best Practices for Designing LED PCBs with Optimal Solder Masks

To fully leverage the benefits of a solder mask LED design, follow these best practices during the PCB design and manufacturing process:

- Match Solder Mask to Substrate: If using a metal-core PCB for better heat dissipation, ensure the solder mask is compatible with the substrate’s thermal expansion properties to avoid cracking.

- Optimize Layout for Reflection: Minimize the coverage of solder mask over areas where LEDs are mounted to maximize direct light output, while ensuring protection for copper traces.

- Test for Performance: Before full-scale production, prototype your LED PCB with the chosen solder mask to measure light output (in lumens) and thermal performance (using infrared thermography).

- Consider Environmental Factors: Account for the operating environment of the LED PCB. For outdoor applications, prioritize UV-resistant and weatherproof solder masks to maintain performance.

Challenges and Solutions in Using White Solder Masks for LED PCBs

While a white solder mask offers significant advantages for light reflection PCB designs, it comes with certain challenges. Here are common issues and how to address them:

Challenge 1: Yellowing Over Time

White solder masks can yellow due to prolonged exposure to UV light or high temperatures, reducing reflectivity. Solution: Select a mask with high UV stability and test it under simulated operating conditions to ensure long-term performance.

Challenge 2: Higher Cost

White and specialty thermal solder masks are often more expensive than standard green masks. Solution: Weigh the cost against the performance benefits. For high-end LED products, the improved light output and thermal management often justify the expense.

Challenge 3: Visibility of Defects

White masks make dirt, scratches, and manufacturing defects more visible compared to darker colors. Solution: Implement strict quality control during manufacturing and assembly to minimize imperfections.

Future Trends in Solder Mask Technology for LED PCBs

As LED technology advances, so does the development of solder masks tailored for these applications. Emerging trends include:

- Nano-Coated Solder Masks: These use nanotechnology to enhance reflectivity and thermal conductivity, pushing light reflection rates above 90%.

- Eco-Friendly Formulations: New solder masks are being developed with environmentally friendly materials that reduce toxicity without compromising performance.

- Smart Thermal Management: Future solder masks may integrate sensors or adaptive materials to dynamically adjust thermal conductivity based on operating conditions.

Staying updated on these innovations can give designers a competitive edge in creating high-performance LED PCBs with optimized solder mask and LED integration.

Conclusion: Enhancing LED PCB Performance with the Right Solder Mask

Choosing the right solder mask is a critical step in designing LED PCBs that deliver superior light output and thermal efficiency. A white solder mask stands out as an excellent choice for boosting light reflection, while specialized thermal PCB solder mask options ensure effective heat dissipation. By carefully considering factors like reflectivity, thermal conductivity, durability, and application methods, you can optimize your LED PCB designs for both performance and longevity.

At ALLPCB, we’re committed to helping you achieve the best results for your LED projects. Whether you’re exploring solder mask LED solutions or fine-tuning a light reflection PCB design, our expertise and resources are here to support you every step of the way. Focus on these key aspects of solder mask selection, and you’ll be well-equipped to create LED PCBs that shine brighter and last longer.