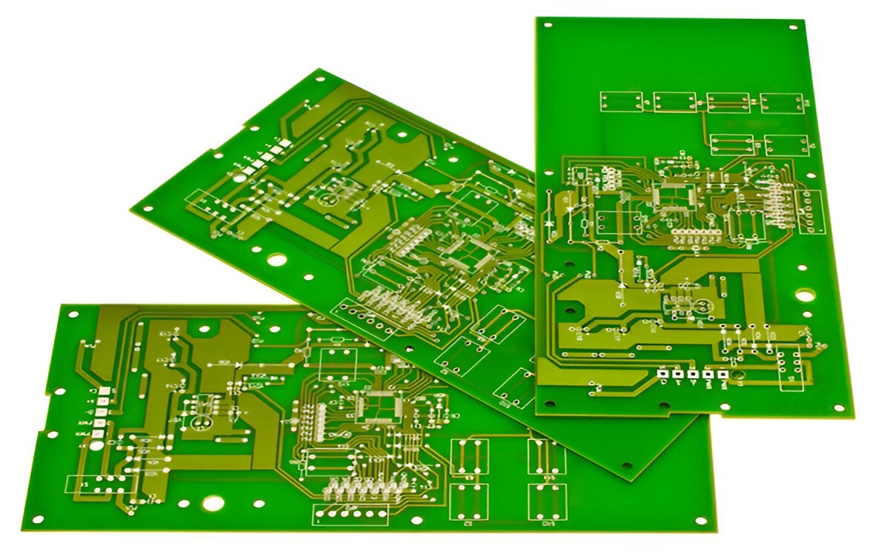

In the fast-evolving world of electronics, single-sided PCBs (Printed Circuit Boards) remain a vital component in many industries despite the rise of more complex multi-layer boards. So, where are single-sided PCB applications still relevant today? They are widely used in consumer electronics, LED lighting, power supplies, and even automotive systems due to their simplicity, cost-effectiveness, and reliability for low-density designs. In this blog, we’ll dive deep into the specific applications of single-sided PCBs across these sectors, providing detailed examples and insights into why they continue to hold value for engineers and manufacturers.

What Are Single-Sided PCBs?

Before exploring their applications, let’s clarify what single-sided PCBs are. These boards have conductive traces on only one side of the substrate, typically made of materials like FR-4 or aluminum. Components are mounted on the same side as the traces, making them simpler to design and manufacture compared to double-sided or multi-layer PCBs. This simplicity translates to lower costs and faster production times, which is why they are still a go-to choice for many low-complexity projects.

Why Single-Sided PCBs Remain Relevant

Single-sided PCBs are not just a relic of the past; they offer unique advantages that keep them relevant. Their low cost makes them ideal for mass production in budget-sensitive projects. Additionally, their straightforward design reduces the risk of manufacturing errors, ensuring reliability for simpler circuits. They also require less time for prototyping and testing, which is critical in industries needing quick turnarounds. With these benefits in mind, let’s explore specific single-sided PCB applications across various fields.

Single-Sided PCB Applications in Consumer Electronics

In consumer electronics, single-sided PCBs are often used in devices where simplicity and affordability are key. These boards are perfect for products that don’t require complex circuitry or high-speed signal transmission. For instance, they are commonly found in basic calculators, remote controls, and low-end toys. These devices typically operate with minimal components and low power, making a single-sided PCB an efficient choice.

A specific example is in low-cost digital thermometers. These devices use a single-sided PCB to connect a temperature sensor, a small display, and a basic microcontroller. The circuit doesn’t need high-density connections or fast data transfer, so a single-sided board meets the requirements while keeping production costs down. According to industry estimates, using single-sided PCBs can reduce manufacturing costs by up to 30% compared to double-sided boards for such simple applications.

Another area within consumer electronics is portable radios. These devices often rely on single-sided PCBs to house basic amplifiers and tuning circuits. The design ensures reliable performance without the need for complex routing, which would be overkill for such straightforward functionality.

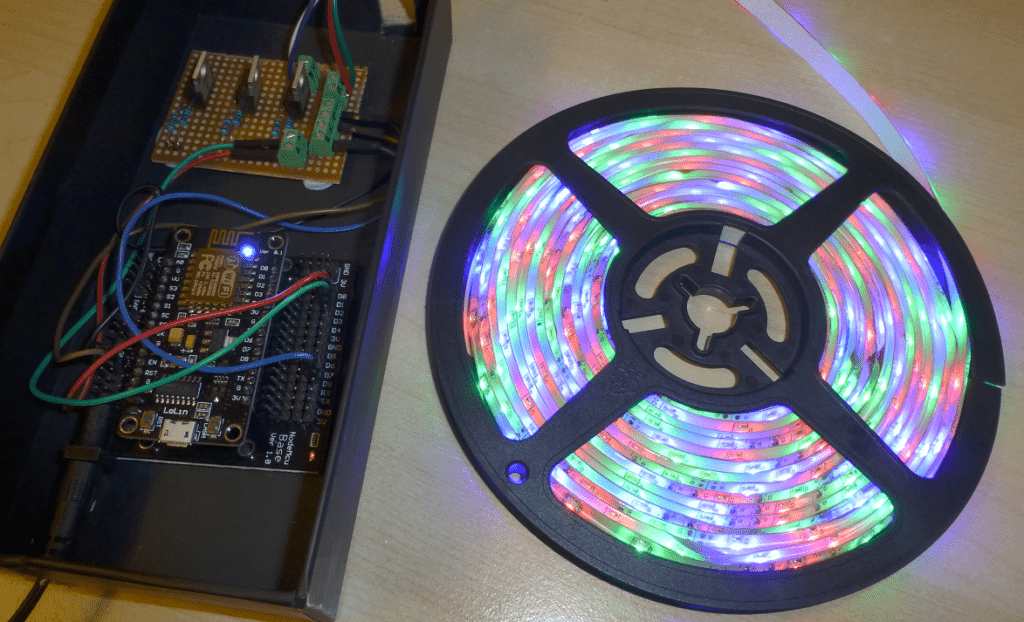

Single-Sided PCB Applications in LED Lighting

LED lighting has become a dominant technology in both residential and commercial spaces due to its energy efficiency and longevity. Single-sided PCB applications in LED lighting are particularly prominent because of the need for cost-effective and thermally efficient designs. These PCBs, often made with aluminum substrates, provide excellent heat dissipation, which is crucial for maintaining LED performance and lifespan.

For example, single-sided PCBs are widely used in LED strip lights. These strips often consist of a long, flexible or rigid board with LEDs mounted in a linear pattern. The single-sided design allows for easy placement of LEDs and resistors on one side, while the aluminum base helps manage heat generated by the LEDs. This setup can handle thermal loads effectively, with some designs dissipating heat at rates up to 2.5 W/m·K, ensuring the LEDs operate within safe temperature ranges (typically below 85°C for optimal lifespan).

Another application is in low-power LED bulbs for household use. These bulbs use single-sided PCBs to connect a small number of LEDs to a driver circuit. The simplicity of the board reduces production costs, making these bulbs affordable for mass markets. This is especially important in regions where price sensitivity drives purchasing decisions.

Single-Sided PCB Applications in Power Supplies

Power supplies, especially those for low to medium power applications, frequently utilize single-sided PCBs due to their reliability and cost advantages. These boards are ideal for circuits that convert AC to DC or regulate voltage in devices like phone chargers, small adapters, and battery management systems.

Take, for instance, a basic 5V USB charger. The internal circuitry often resides on a single-sided PCB, where components like rectifiers, capacitors, and voltage regulators are mounted. The design doesn’t require high-speed signal processing or complex layering, so a single-sided board suffices. Such chargers can deliver output currents of up to 2A with stable performance, meeting the needs of most consumer devices while keeping production costs low.

Another example is in solar charge controllers for small off-grid systems. These controllers manage power flow between solar panels and batteries, using simple circuits on single-sided PCBs. The boards handle low-frequency signals and moderate power levels (often below 10A), making them a perfect fit for this application. Their design simplicity also aids in field repairs, as troubleshooting is easier compared to multi-layer boards.

Single-Sided PCB Applications in Automotive

The automotive industry, while increasingly reliant on complex electronics, still finds value in single-sided PCB applications for specific components. These boards are often used in non-critical systems or where cost and simplicity outweigh the need for high-density designs. They are particularly useful in environments where durability and ease of maintenance are priorities.

One common application is in interior lighting systems, such as dashboard lights or dome lights. Single-sided PCBs, often with aluminum substrates for heat management, support low-power LEDs used in these systems. For instance, a dashboard light circuit might operate at 12V with a current draw of less than 500mA, well within the capabilities of a single-sided design. This approach keeps costs down while ensuring reliable illumination over the vehicle’s lifespan.

Another example is in basic sensor modules, such as those used for door or seatbelt alerts. These modules rely on simple circuits to detect open/closed states and trigger warnings. A single-sided PCB can easily accommodate the necessary components, like switches and resistors, without the complexity of additional layers. This simplicity also enhances durability in the harsh automotive environment, where vibrations and temperature fluctuations (ranging from -40°C to 85°C) are common.

Single-Sided PCB Applications Examples: Real-World Use Cases

To tie these applications together, let’s look at a few more detailed single-sided PCB applications examples across industries. These cases highlight how versatile and practical these boards remain in modern designs.

- Electronic Timers: Used in kitchen appliances like microwaves, electronic timers often feature single-sided PCBs. These boards manage basic countdown functions and relay control with minimal components, operating at low frequencies (typically under 1kHz). This keeps costs low while ensuring reliable operation.

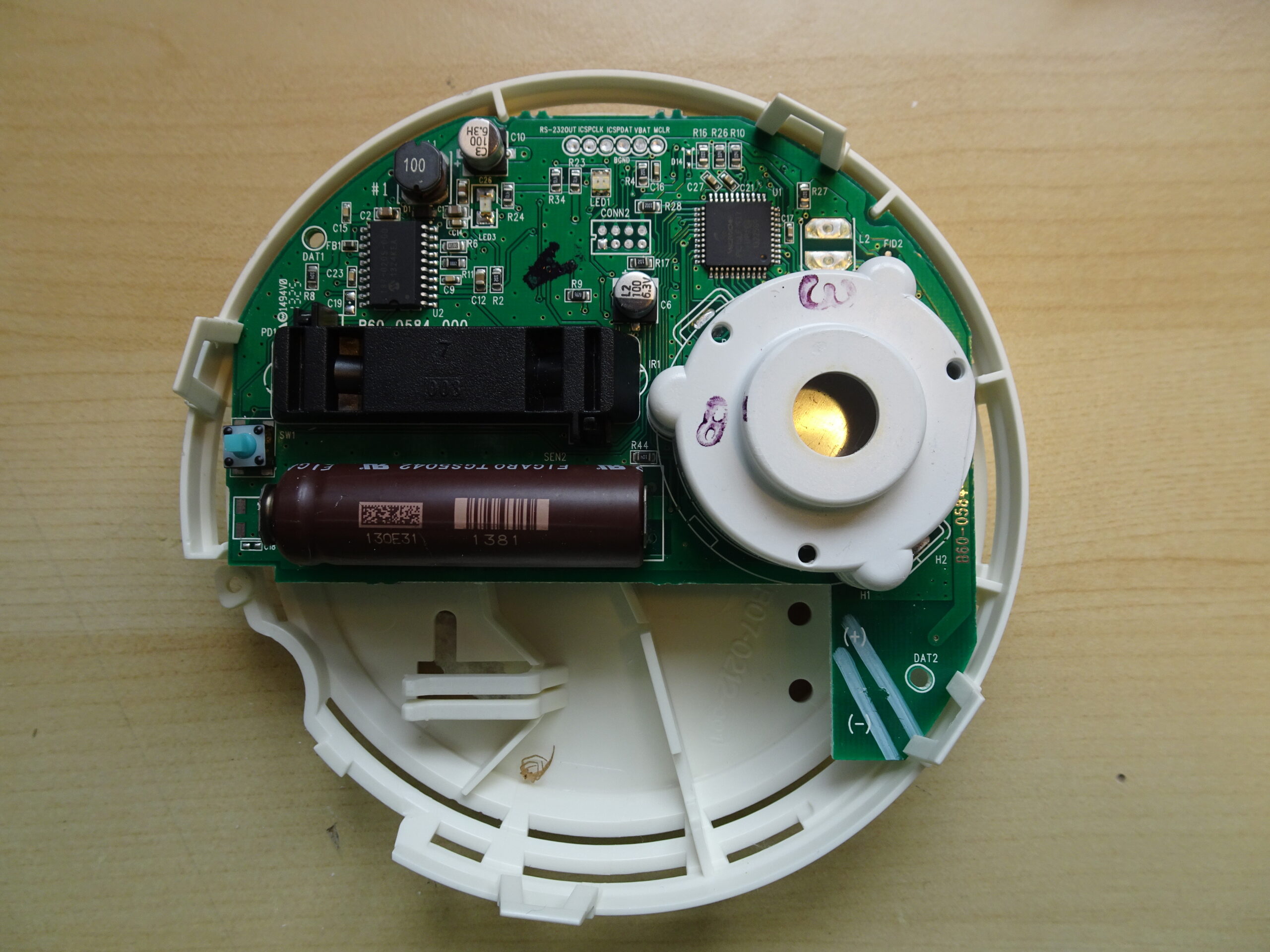

- Smoke Detectors: Many residential smoke detectors use single-sided PCBs to connect sensors, alarms, and power circuits. The design handles low-power signals and doesn’t require complex routing, making it an economical choice for mass-produced safety devices.

- Basic Motor Controllers: In small appliances like fans or toy cars, single-sided PCBs control motor speed and direction. These circuits often operate at voltages below 24V and currents under 1A, fitting well within the capabilities of a single-sided layout.

These examples demonstrate that single-sided PCBs are not obsolete but instead fill a critical niche in applications where cost, simplicity, and reliability are paramount.

Advantages and Limitations of Single-Sided PCBs

Understanding the strengths and weaknesses of single-sided PCBs helps engineers decide when to use them. On the plus side, they offer low production costs, quick turnaround times, and ease of troubleshooting. They’re also less prone to manufacturing defects due to their simplicity. However, they have limitations, such as restricted space for components and inability to handle high-speed or high-frequency signals (typically above 100MHz). For complex designs with dense circuitry, double-sided or multi-layer boards are more suitable.

How to Design Effective Single-Sided PCBs for Your Applications

For engineers looking to leverage single-sided PCBs, a few design tips can maximize their effectiveness. First, prioritize component placement to minimize trace lengths, reducing potential signal interference. Keep power and ground traces wider (often 0.5mm or more) to handle current loads safely. Use thermal vias or aluminum substrates if heat dissipation is a concern, especially in LED or power supply applications. Finally, simulate the circuit design to ensure it meets performance needs before manufacturing, as revisions can be costly even for simple boards.

Conclusion: The Enduring Value of Single-Sided PCBs

Single-sided PCBs continue to play a crucial role in modern electronics, proving that simplicity can still be powerful. From single-sided PCB applications in consumer electronics like remote controls to their use in LED lighting, power supplies, and automotive systems, these boards offer a cost-effective and reliable solution for low-density designs. By understanding their strengths and ideal use cases, engineers can make informed decisions to optimize performance and budget in their projects. As technology advances, single-sided PCBs remind us that not every solution needs to be complex to be effective.

Whether you’re designing a basic charger or an automotive lighting module, consider the potential of single-sided PCBs. Their relevance endures in applications where cost and simplicity are key, ensuring they remain a staple in the electronics industry for years to come.

ALLPCB

ALLPCB