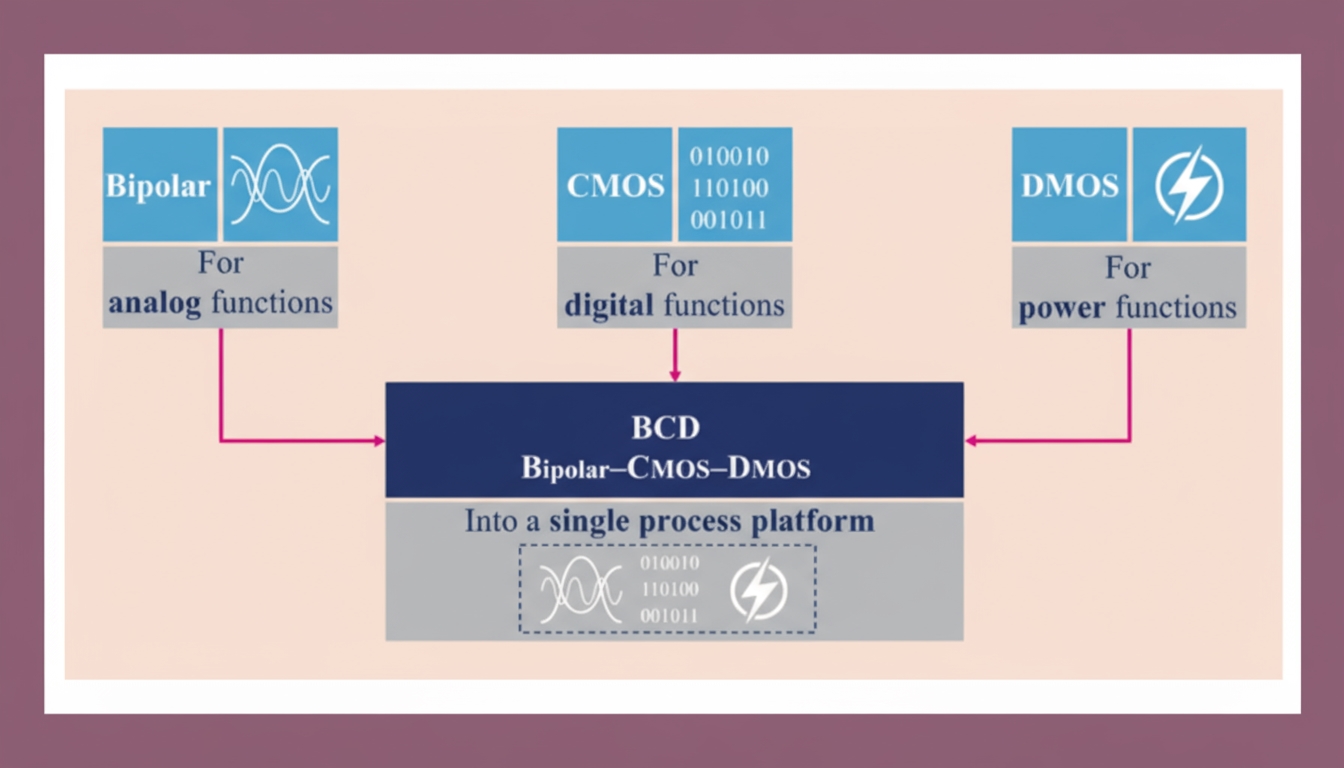

In the semiconductor sector, Weebit Nano and DB HiTek announced a strategic collaboration to integrate Weebit's resistive random-access memory (ReRAM) into DB HiTek's 130 nm bipolar-CMOS-DMOS (BCD) process for power management semiconductor designs. This integration represents an important step for analog, mixed-signal, and power-design semiconductors.

1) Monolithic integration and design simplification

One key objective of combining ReRAM and BCD technologies is to achieve monolithic integration that allows analog, digital, and power components to coexist on the same chip. This approach simplifies the design flow and can improve overall system performance by reducing the complexity associated with external components and multiple chips.

DB HiTek's adoption of Weebit's ReRAM sets a precedent for other foundries and semiconductor manufacturers to evaluate integrating ReRAM into their processes. ReRAM's versatility makes it applicable across many markets, from consumer electronics to industrial systems and IoT devices, enabling new options for system-level innovation and customization.

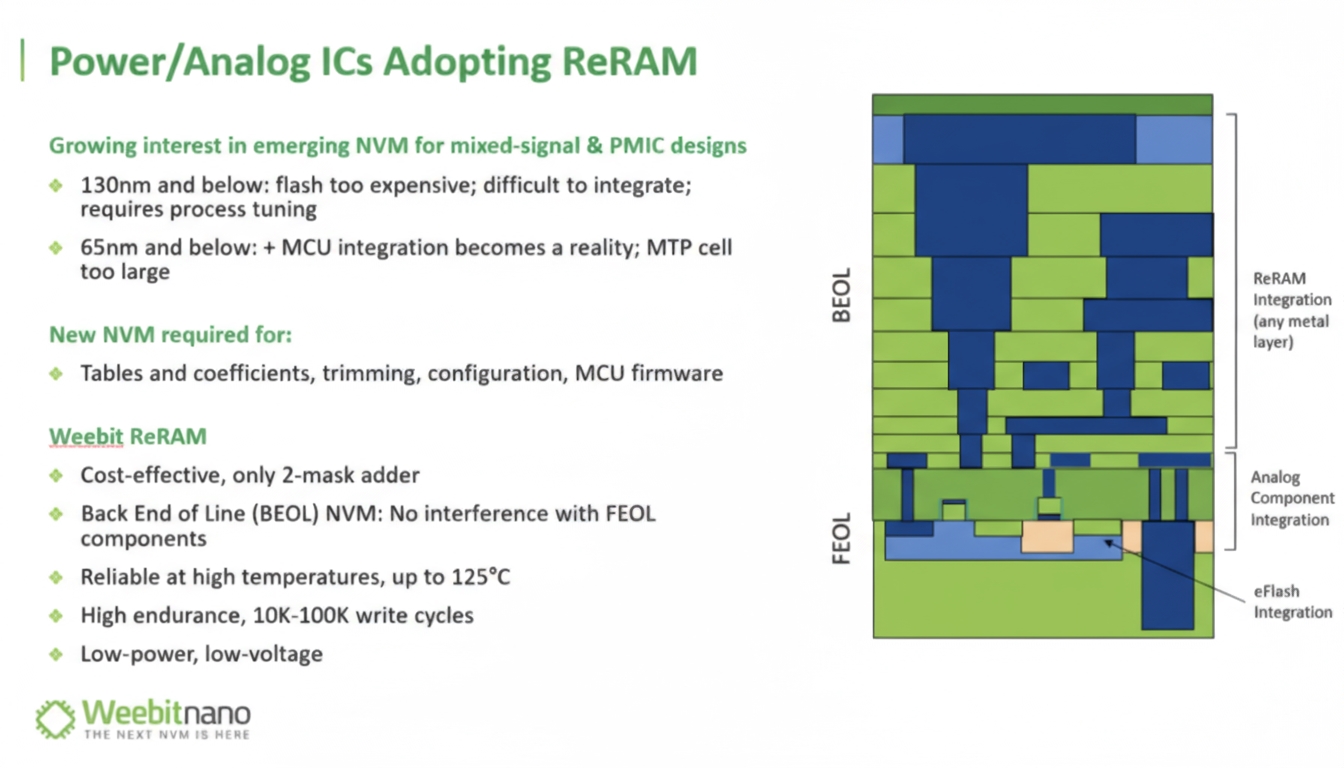

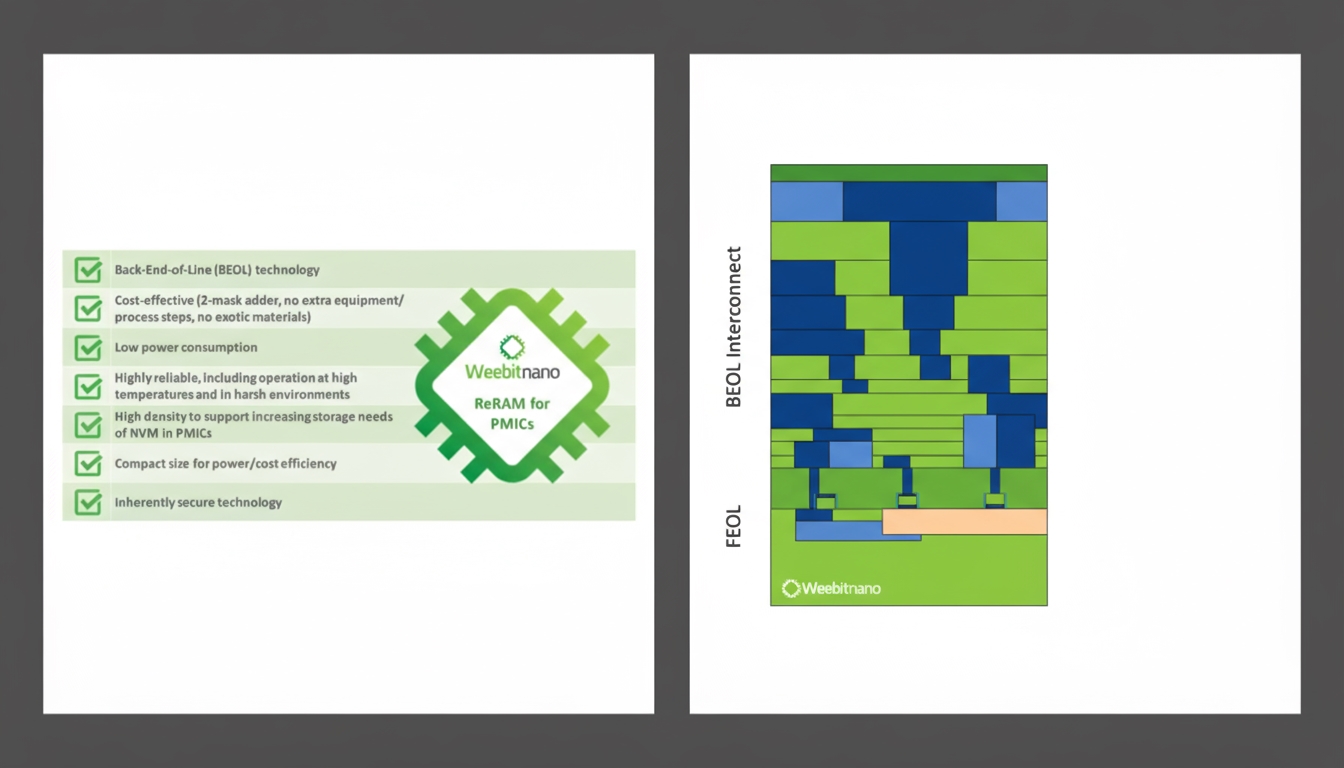

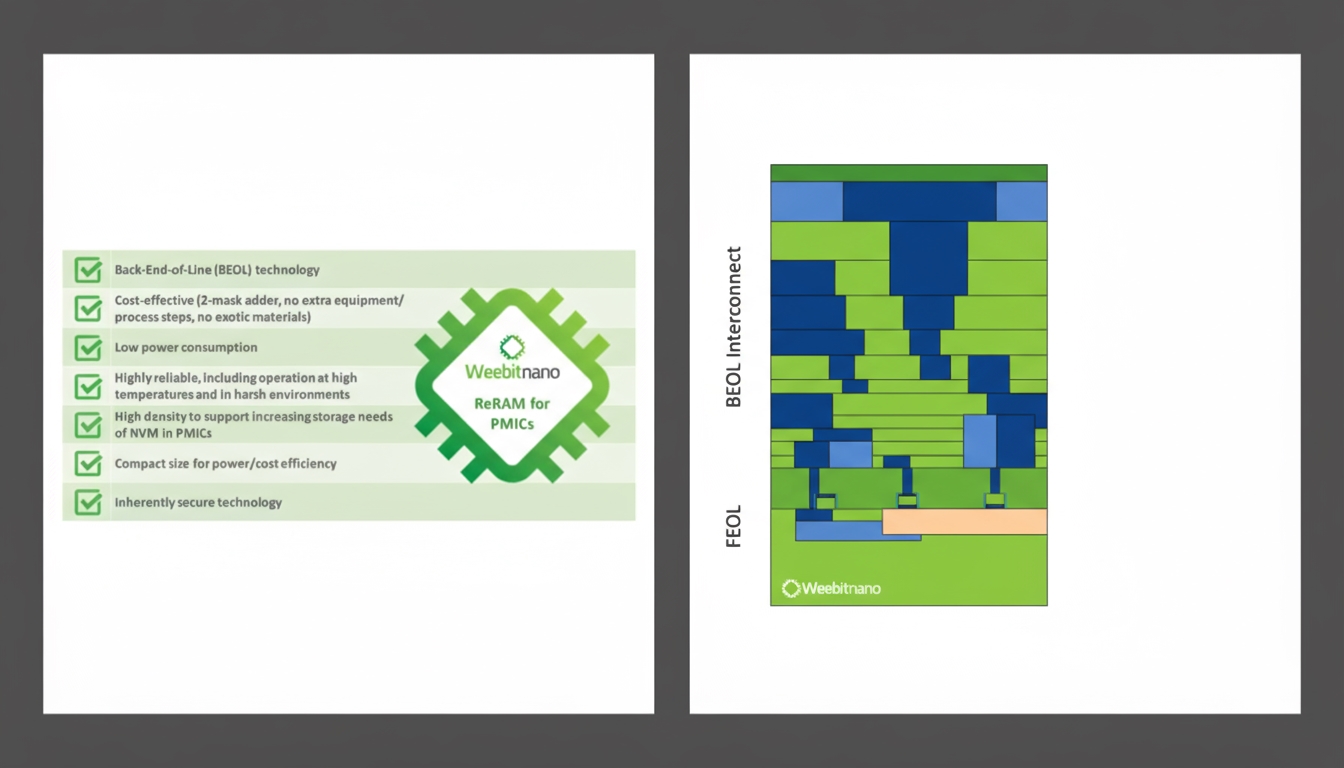

As a back-end-of-line (BEOL) technology, ReRAM is integrated in later stages of semiconductor manufacturing. This integration method minimizes interference with front-end components and allows direct incorporation into existing BCD flows. ReRAM's simple stack structure facilitates BEOL integration with minimal process changes. Combined with high endurance, good high-temperature reliability, and low power use, ReRAM can be a favorable choice compared with embedded flash in BCD processes. The simplified integration and reduced process adjustments can improve overall design efficiency and performance.

Key advantages of integrating ReRAM into DB HiTek's BCD process include:

- Cost-effective manufacturing: Weebit's ReRAM requires only two additional masks during fabrication, whereas flash typically needs more than ten, directly affecting manufacturing cost and cycle time.

- Improved system integration: ReRAM in BCD enables analog, digital, and power components to coexist on a single chip, streamlining the design process.

- Energy efficiency: ReRAM's low-power characteristics combined with BCD power-management functions can improve overall energy efficiency, which is important for mobile and battery-powered applications.

- Versatility and customization: The collaboration enables semiconductor designers to tailor integrated circuits to specific application requirements.

From consumer devices to industrial control systems and IoT equipment, ReRAM in BCD processes can influence future semiconductor design choices across multiple application domains.

2) Implications for PMICs

PMICs, or power management integrated circuits, are central to modern electronic systems. PMICs control power distribution and set voltage levels for various components, such as CPUs, DACs, ADCs, and I/O devices. Because different components often require different voltages, many products use multiple voltage rails, and PMICs ensure correct voltages for each component. PMICs also act as conduits from external power sources, like batteries or wall adapters, to system components.

BCD technology enables integration of bipolar analog elements, CMOS digital logic, and high-voltage DMOS transistors on the same chip, which simplifies PMIC design and supports integration of PMIC, analog, and power components into a single device.

As products become more complex, PMIC design faces greater challenges. Modern PMICs often include preprogrammed and adjustable functions and support field upgrades, allowing them to adapt to changing system requirements. The PMIC market is expected to grow to over $25.6 billion by 2026, with mobile and consumer markets representing the largest share. Multi-channel PMICs, which provide different voltages to various loads, account for much of this growth. Automotive and industrial applications are expected to grow fastest, driven by advanced driver-assistance systems (ADAS) and electric vehicles that increasingly rely on PMICs.

Historically, power management focused on adjusting voltages to meet product requirements. As electronic systems grew more complex, PMICs incorporated non-volatile memory (NVM) to manage voltage settings. Initially, simple EEPROM was used, but NVM functionality within PMICs has become more important over time. The industry is seeking alternatives to embedded flash memory, and BEOL NVM technologies have gained attention because they can be integrated on the back end without compromising analog components.

Among BEOL NVM options, ferroelectric RAM (FRAM) is limited by high-temperature requirements, while magnetoresistive RAM (MRAM) can typically withstand high temperatures but often involves greater complexity and higher manufacturing cost, making it less suitable for analog markets. ReRAM, with simplified integration and cost-effective manufacturability, offers a promising alternative for PMICs and analog power-management components.

ALLPCB

ALLPCB