In recent years, the demand for motion control systems has increased due to rapid industrial development. Traditional PC-based and low-end microcontroller-based systems are often insufficient for modern manufacturing process requirements. As embedded technology matures, embedded motion controllers are becoming dominant in the industrial automation market. ARM-based microprocessors, known for their small size, low cost, and low power consumption, show significant potential in the industrial automation motion control sector.

System Introduction

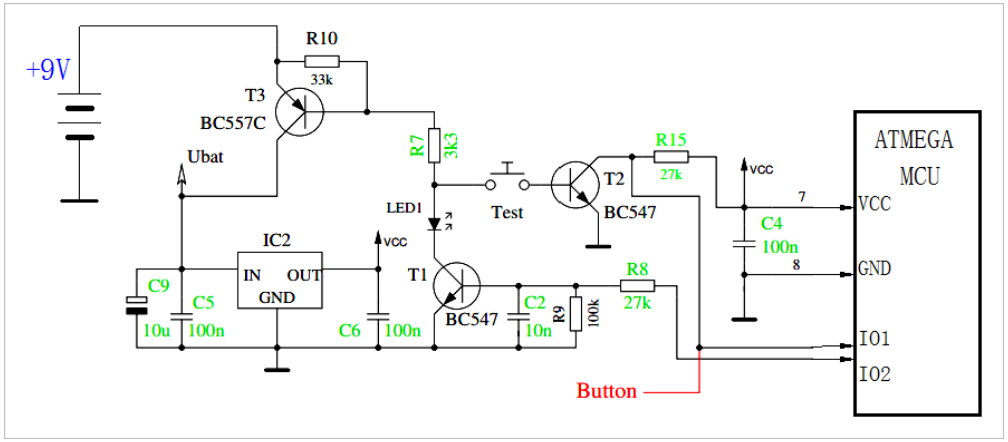

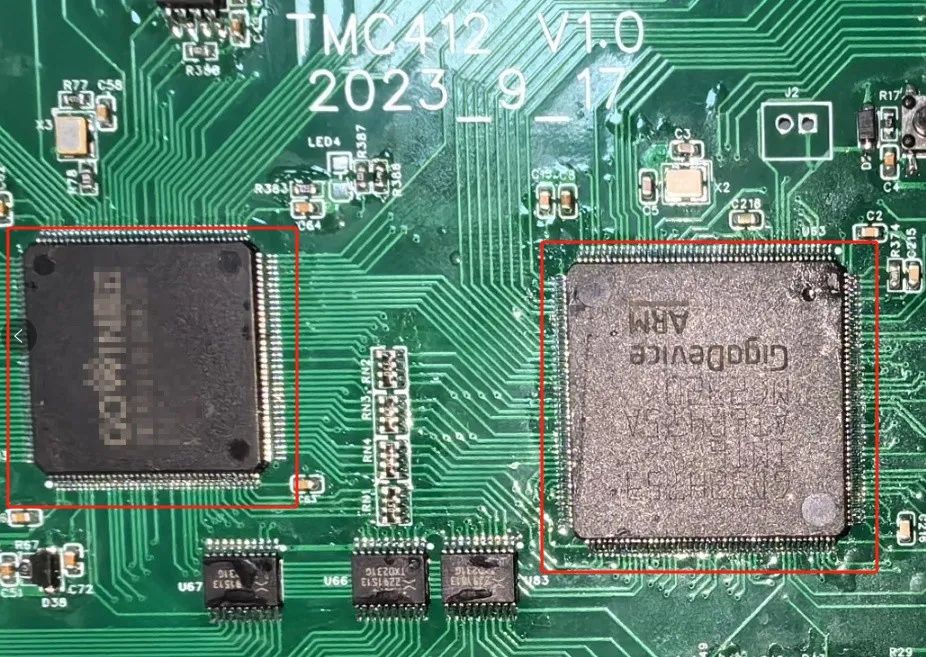

Leveraging the data processing capabilities of the GD32H759 series high-performance MCU, this hardware design uses an ARM + FPGA architecture. The motion control system's overall design includes a serial communication program using MODBUS-RTU/TCP and a custom protocol. It uses a dynamic table to store motion control information from the HMI, enabling human-machine interaction through the HMI screen. The hardware platform is illustrated below.

System Framework

In this system, the ARM processor acts as the main controller, handling system triggers, command dispatch, task scheduling, and context switching. The FPGA serves as a peripheral to the ARM, receiving and parsing processed data to execute commands for pulse generation, pulse counting, and motion task management.

Most industrial automation motion control applications require real-time performance, efficient data processing, and practical applicability. The ARM + FPGA hardware design uses the ARM (GD32H759) as the main control chip, responsible for motor parameter settings, interpolation calculations, human-machine interaction, and processing file management. The auxiliary FPGA chip handles pulse output for each axis, origin detection, and input signal processing.

Key specifications for the controller are listed in the table below:

| Parameter | Specification |

|---|---|

| Power Consumption | < 5W |

| Voltage | 24 VDC |

| Number of Axes | 12 |

| Max Pulse Frequency | 4 MHz (single axis) |

| Serial Ports | 2x RS-232, 1x RS-485, 1x RJ45 |

| I/O Points | 24 inputs, 24 outputs |

| I/O Expansion | Supported |

Comparing ARM + FPGA and ARM + DSP architectures reveals distinct advantages. The FPGA architecture excels at generating multiple pulse drive waves, making it well-suited for multi-axis coordination, motion control, and I/O expansion. The DSP architecture's strength lies in its ability to perform complex data calculations.

In the overall design, the FPGA is mapped to the ARM's address space and functions as a peripheral. To execute a task, the ARM first runs an instruction containing the FPGA's address to select the device. Once selected, the FPGA detects the address data sent by the ARM on the address bus, parses the data transmitted on the bus, and then begins its operation. Registers are a critical part of motion control. The ARM achieves control over the FPGA by pre-configuring its internal registers.

Advantages of the Solution

The GD32H759 provides significant computational performance. The ARM + FPGA architecture enables simultaneous motion control for a larger number of axes. Compared to an ARM + DSP architecture for similar requirements, this approach can offer a lower hardware cost.

The GD32H759 has demonstrated high stability and scalability in practical applications.

In industrial automation, customer requirements are shifting from single-purpose machines to multi-purpose systems. This evolution demands robust motion controllers with strong capabilities in data processing, data storage, I/O configuration, and multi-axis linkage. The ARM + FPGA architecture featuring the GD32H759 provides a flexible platform to meet these market needs.

The controller platform based on the GD32H759 and FPGA architecture supports higher pulse frequencies than some previous platforms. It offers greater configurability, wider applicability in specialized environments, and faster control processing, which can significantly reduce machining time.

ALLPCB

ALLPCB