In the fast-evolving world of electronics, managing heat in high-power applications is a critical challenge. If you're searching for a reliable solution to keep your devices cool and efficient, Metal Core PCBs (MCPCBs) might just be your answer. These specialized circuit boards are designed to handle intense heat, making them a game-changer for industries like LED lighting, automotive, and power electronics. In this comprehensive guide, we'll dive deep into the world of metal core PCB thermal conductivity, MCPCB design, and their various applications, helping you understand why they are the go-to choice for thermal management.

What Are Metal Core PCBs and Why Do They Matter?

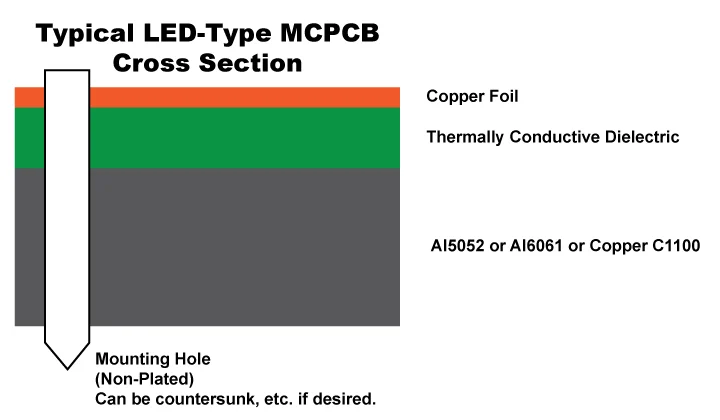

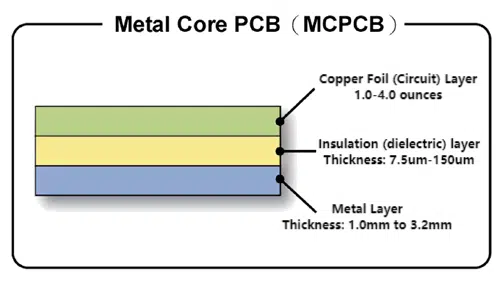

Metal Core PCBs, often referred to as MCPCBs or IMS (Insulated Metal Substrate) PCBs, are a type of printed circuit board that uses a metal base layer instead of the traditional FR4 material. This metal layer—usually aluminum or copper—acts as a heat sink, efficiently dissipating heat away from critical components. Unlike standard PCBs, which struggle with thermal conductivity, MCPCBs excel in high-power environments where heat buildup can damage components or reduce performance.

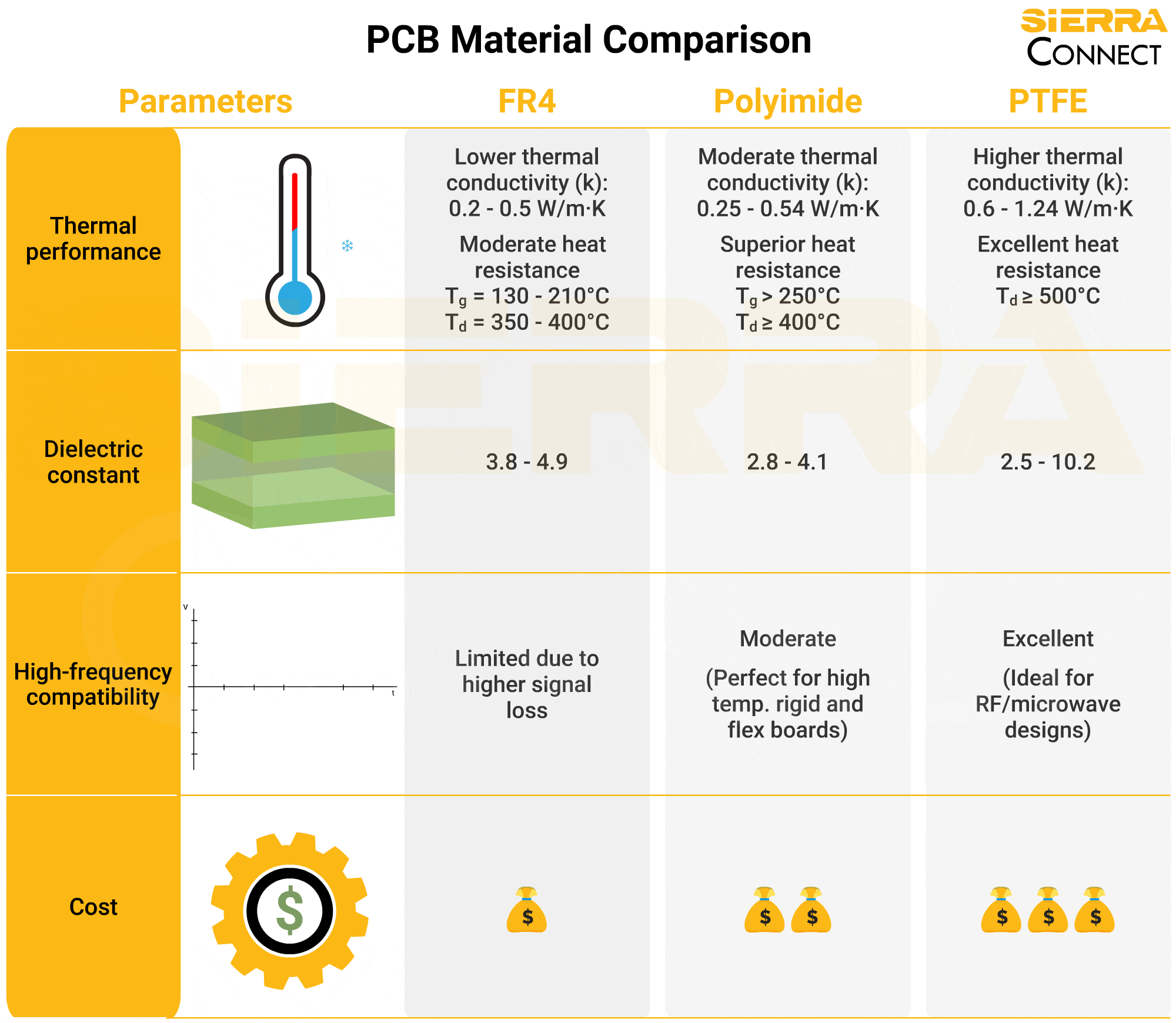

Why does this matter? As electronic devices become smaller and more powerful, heat dissipation becomes a bigger problem. Overheating can lead to reduced lifespan, system failures, or even safety hazards. With a thermal conductivity range of 1 to 8 W/mK for aluminum PCBs and up to 400 W/mK for copper core PCBs, MCPCBs offer a superior solution compared to FR4 boards, which typically hover around 0.3 W/mK. This makes them indispensable for modern electronics.

The Science Behind Metal Core PCB Thermal Conductivity

At the heart of MCPCB performance is its thermal conductivity—the ability to transfer heat away from heat-generating components. Traditional FR4 boards rely on thin copper traces and insulating materials that trap heat, leading to hotspots. In contrast, metal core PCBs use a thick metal base that spreads heat evenly across the board and into the surrounding environment or attached heat sinks.

Aluminum PCBs, one of the most common types of MCPCBs, typically offer thermal conductivity between 1 and 8 W/mK, depending on the alloy and thickness. Copper core PCBs, while more expensive, can achieve conductivity values as high as 400 W/mK, making them ideal for extreme high-power applications. The dielectric layer, which insulates the metal base from the copper circuitry, also plays a role. Advanced dielectric materials can maintain electrical insulation while allowing heat to pass through, often with conductivity values of 1.5 to 3 W/mK.

This superior heat dissipation ensures that components like power transistors, LEDs, and microprocessors operate within safe temperature ranges, extending their lifespan and reliability. For instance, in LED lighting, where heat can degrade brightness and color over time, an aluminum PCB can reduce operating temperatures by 20-30°C compared to a standard board.

Key Materials in MCPCB Design: Aluminum PCB vs. Copper Core PCB

When it comes to MCPCB design, the choice of metal base material is critical. Let's break down the two most popular options: aluminum and copper.

Aluminum PCB: Lightweight and Cost-Effective

Aluminum PCBs are the most widely used type of metal core PCB due to their balance of performance and cost. With a thermal conductivity of 1-8 W/mK, aluminum efficiently dissipates heat for most high-power applications. It’s also lightweight, with a density of about 2.7 g/cm3, which is ideal for portable devices or automotive systems where weight is a concern. Additionally, aluminum is corrosion-resistant and recyclable, adding to its appeal for sustainable designs.

Copper Core PCB: Ultimate Thermal Performance

For applications requiring maximum heat dissipation, copper core PCBs are the top choice. Copper boasts an impressive thermal conductivity of around 400 W/mK, far surpassing aluminum. This makes it perfect for extreme environments, such as high-current power supplies or industrial equipment. However, copper is heavier (density of 8.96 g/cm3) and more expensive, so it’s often reserved for specialized uses where cost is less of a factor than performance.

Both materials can be paired with high-quality dielectric layers to ensure electrical insulation while maintaining thermal efficiency. The choice between aluminum and copper often comes down to the specific thermal and budgetary needs of the project.

Understanding IMS PCB: A Closer Look at Insulated Metal Substrate

IMS PCB, or Insulated Metal Substrate PCB, is another term often used interchangeably with MCPCB. The “insulated” part refers to the dielectric layer that separates the metal base from the copper circuitry. This layer is crucial because it prevents electrical shorts while allowing heat to transfer from the components to the metal core.

In IMS PCB design, the dielectric material is typically a thin polymer or ceramic layer with high thermal conductivity (1.5-3 W/mK) and excellent electrical insulation properties (dielectric strength of 20-30 kV/mm). This ensures that even in high-voltage applications, the board remains safe and efficient. IMS PCBs are particularly popular in LED lighting and power electronics, where both thermal management and electrical safety are paramount.

Metal Core PCB Applications: Where They Shine

The unique properties of metal core PCBs make them indispensable across a wide range of industries. Here are some key metal core PCB applications where their thermal management capabilities truly shine:

- LED Lighting: High-power LEDs generate significant heat, which can affect performance and lifespan. Aluminum PCBs are commonly used in LED streetlights, automotive headlights, and indoor lighting to keep temperatures under control, often reducing operating heat by 20-30°C.

- Automotive Electronics: From engine control units to electric vehicle battery management systems, MCPCBs handle the heat and vibration challenges of automotive environments. Their lightweight design (especially with aluminum) also helps improve fuel efficiency.

- Power Electronics: Devices like power supplies, inverters, and motor controllers rely on copper core PCBs to manage high current and heat loads, ensuring stable operation under demanding conditions.

- Industrial Equipment: In heavy machinery and industrial automation, MCPCBs provide reliable thermal management for control systems and power modules, reducing downtime caused by overheating.

- Consumer Electronics: High-performance devices like gaming consoles and laptops use MCPCBs to manage heat in compact spaces, improving user safety and device longevity.

MCPCB Design Tips for Optimal Thermal Management

Designing an effective metal core PCB requires careful consideration of several factors to maximize thermal performance. Here are some practical tips for MCPCB design:

- Choose the Right Metal Base: Select aluminum for cost-effective, lightweight designs or copper for high-end, high-power applications. Consider the thermal conductivity needs based on your components’ heat output.

- Optimize Dielectric Layer: Use a dielectric material with high thermal conductivity (at least 1.5 W/mK) and sufficient dielectric strength to handle your voltage requirements.

- Component Placement: Place heat-generating components close to the metal core or heat sink areas to maximize heat transfer. Avoid clustering high-power components in one spot to prevent localized hotspots.

- Thermal Vias: Incorporate thermal vias to enhance heat flow from the top layer to the metal base. A via density of 10-15 per square inch near high-heat components can improve dissipation by up to 15%.

- Heat Sink Integration: Attach external heat sinks or cooling systems directly to the metal core for additional cooling. Ensure a tight thermal interface with thermal paste or pads to minimize resistance.

By following these design principles, you can create an MCPCB that not only manages heat effectively but also enhances the overall reliability of your electronic system.

Advantages of Metal Core PCBs Over Traditional Boards

Metal core PCBs offer several advantages over standard FR4 boards, especially in high-power scenarios. Here’s why they’re often the preferred choice:

- Superior Thermal Conductivity: With values ranging from 1 to 400 W/mK depending on the material, MCPCBs far outperform FR4 boards (0.3 W/mK), reducing component temperatures significantly.

- Improved Durability: The metal base provides mechanical strength, making MCPCBs more resistant to vibration and physical stress, ideal for harsh environments.

- Compact Designs: Better heat dissipation allows for smaller, more densely packed designs without risking overheating, saving space in modern electronics.

- Longer Component Lifespan: Lower operating temperatures reduce thermal stress on components, extending their operational life by 20-30% in some cases.

- Lightweight Options: Aluminum PCBs offer a lightweight alternative to traditional boards, beneficial for portable and automotive applications.

Challenges and Limitations of Metal Core PCBs

While MCPCBs are a powerful solution for thermal management, they do come with some challenges:

- Higher Cost: Compared to FR4 boards, MCPCBs are more expensive due to the metal base and specialized manufacturing processes. Copper core PCBs, in particular, can be cost-prohibitive for budget-sensitive projects.

- Design Complexity: The integration of a metal core and dielectric layer requires precise engineering to balance thermal and electrical performance, which can complicate the design process.

- Weight Considerations: While aluminum is lightweight, copper core PCBs are heavier, which may not be suitable for applications where weight is a critical factor.

Despite these challenges, the benefits of MCPCBs often outweigh the drawbacks, especially in applications where thermal management is non-negotiable.

Conclusion: Why Metal Core PCBs Are the Future of Thermal Management

As electronics continue to push the boundaries of power and performance, effective thermal management is more important than ever. Metal Core PCBs, with their exceptional thermal conductivity and robust design, stand out as a secret weapon for tackling heat in high-power applications. Whether you’re working on LED lighting, automotive systems, or industrial equipment, understanding metal core PCB thermal conductivity, MCPCB design principles, and the differences between aluminum PCB and copper core PCB options can help you make informed decisions for your projects.

By leveraging the strengths of IMS PCBs and tailoring their applications to your specific needs, you can ensure your devices operate efficiently, safely, and reliably. Ready to take your thermal management to the next level? Metal Core PCBs are the key to unlocking superior performance in even the most demanding environments.

ALLPCB

ALLPCB