Although many consider PID (proportional-integral-derivative) controllers simple or "low-end", their dominance in industrial control remains hard to displace.

01 Simple and Practical

PID controllers are practical and effective. They are based on simple mathematical principles and control the system error by adjusting three parameters: the proportional gain P, the integral gain I, and the derivative gain D. This simplicity makes PID controllers easy to understand and implement while providing stable and reliable control.

02 Wide Applicability

PID controllers apply to a variety of industrial processes, including temperature, pressure, flow, and level control. This versatility allows engineers to use the same control approach across different control systems without designing complex custom solutions for each case.

03 Robustness

PID controllers have strong robustness, meaning they can adapt to model uncertainties and external disturbances. Even when the system model is not perfectly accurate or the system experiences external interference, a PID controller can maintain stable operation.

04 Easy to Tune

PID parameters are relatively straightforward to tune and can be optimized through experiments or simulation. This allows engineers to quickly find settings that meet control requirements, improving process efficiency and product quality.

The main advantage of PID is that we often know the output variable is a function of the input variable, but deriving that function can be difficult or the relationship can be complex. In such cases, PID provides a relatively simple way to achieve control. For example, in pipeline gas pressure control, we measure the output pressure and feed it to a PID controller, which can then adjust a diaphragm valve to control pressure. Another example is furnace temperature control: a thermocouple is connected to a temperature controller, which uses PID and outputs a 4-20 mA signal to a thyristor power regulator to control the heating element and thus the temperature. These are single-variable systems and relatively simple, so PID is widely used in industrial control.

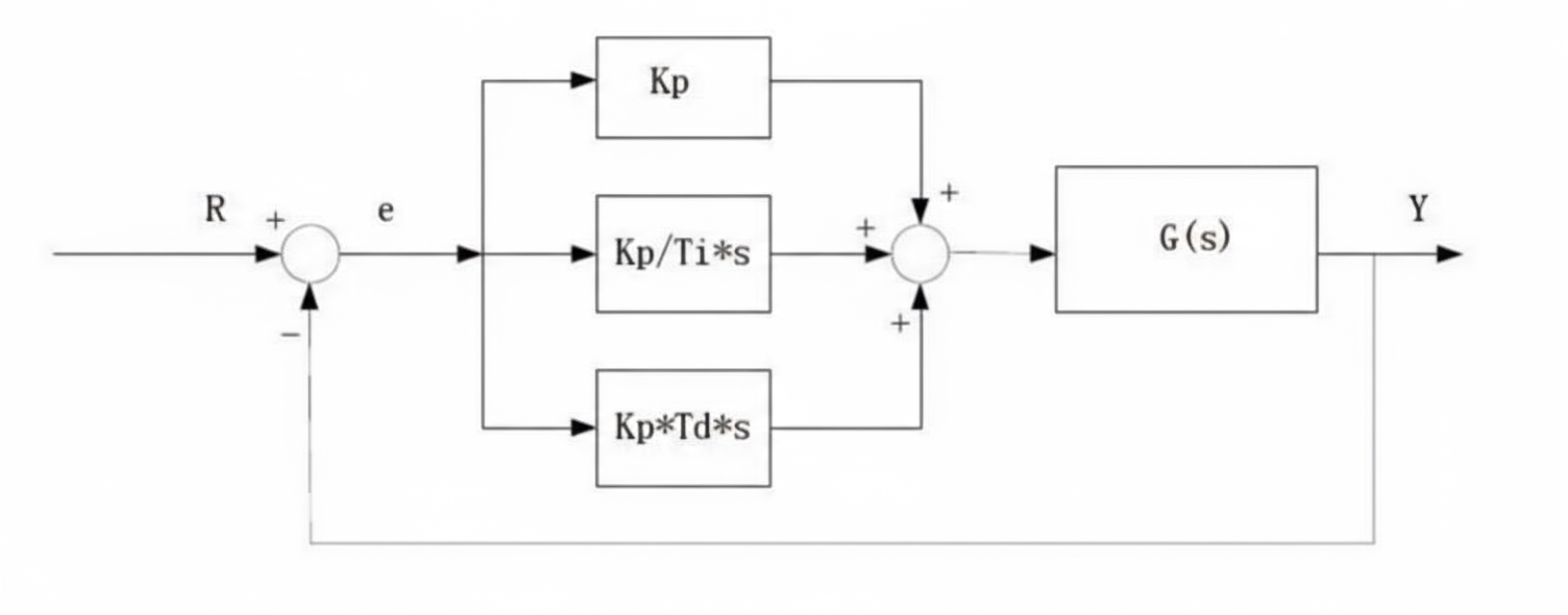

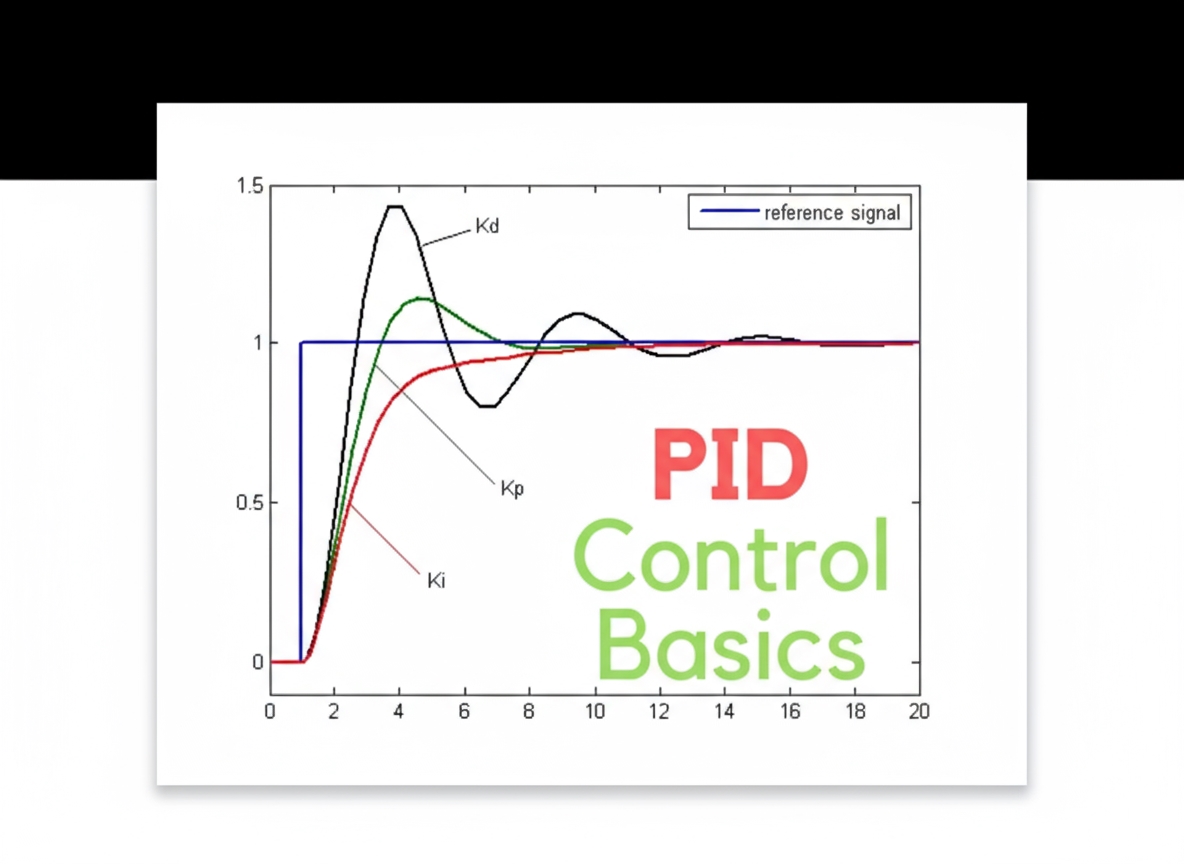

Figure 1: Simple PID control

Figure 2: Simple PID control

From Figures 1 and 2, it is clear that a functional relationship exists between the output and the input, but deriving it can be cumbersome. Using a PID controller avoids handling the explicit function and makes measurement and control straightforward.

Although advanced control algorithms such as fuzzy control and neural network control have emerged in recent years and can outperform PID in specific scenarios, PID remains the dominant choice in industrial control. Its simplicity, practicality, and robustness make it a reliable and cost-effective solution for most industrial processes. Most importantly, PID is widely understood by practitioners in the field.

ALLPCB

ALLPCB