As automotive technology advances and vehicle intelligence increases, electronic fuses (e-Fuse) are progressively replacing traditional fuses as key components in vehicle electrical systems.

Compared with conventional fuses, e-Fuse offers longer life, faster response, self-recovery, smaller size, richer functionality, and lower maintenance costs. These characteristics lead to broad application in autonomous driving developments, low-voltage system upgrades, and E/E architecture improvements.

Part 1 — Advantages: e-Fuse vs traditional fuses

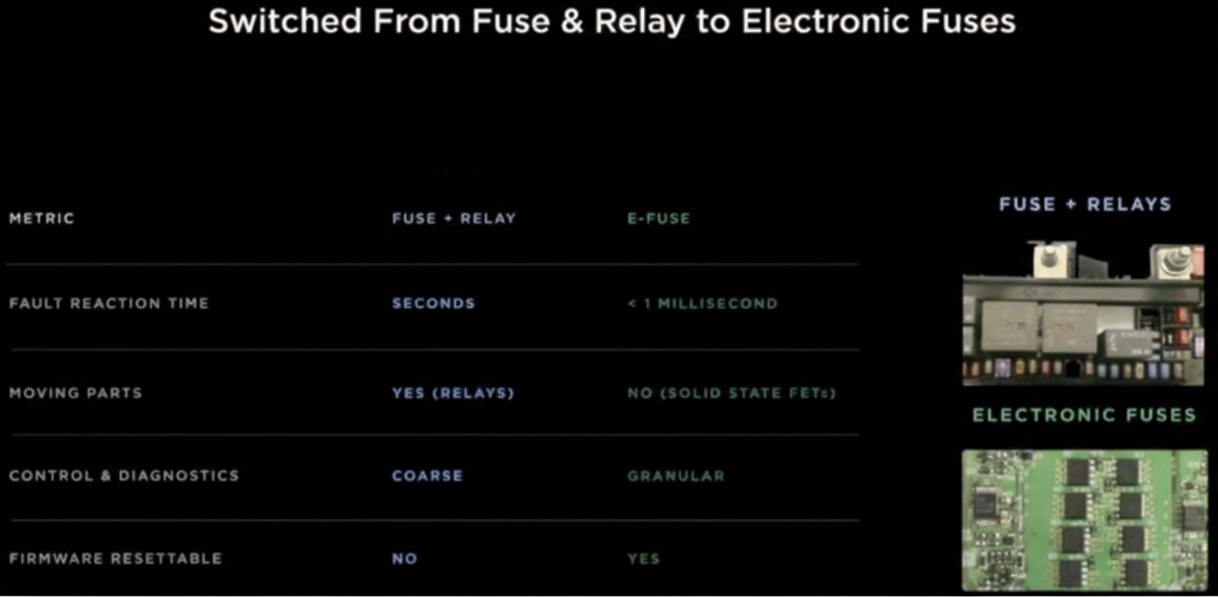

e-Fuse is a programmable, upgradeable, and diagnosable electronic fuse that replaces traditional relays and fuses with a combination of a control chip and power semiconductor switches. Compared with traditional solutions, it offers the following advantages:

- Longer life: With no mechanical contacts, e-Fuse typically has a longer service life than conventional relays.

- Faster response: e-Fuse can provide rapid short-circuit protection, cutting off current far faster than traditional fuses and effectively limiting transient voltage drop and large current events.

- Self-recovery: After a transient fault clears, e-Fuse can automatically recover, whereas traditional fuses must be replaced.

- Smaller size: The compact form factor of e-Fuse facilitates optimized vehicle layout.

- Richer functionality: e-Fuse supports programmability and diagnostics, enabling compatibility with vehicle intelligent systems and varied application requirements.

- Lower maintenance cost: The self-recovery capability of e-Fuse can reduce maintenance and replacement needs.

Part 2 — Technical principles and application scenarios

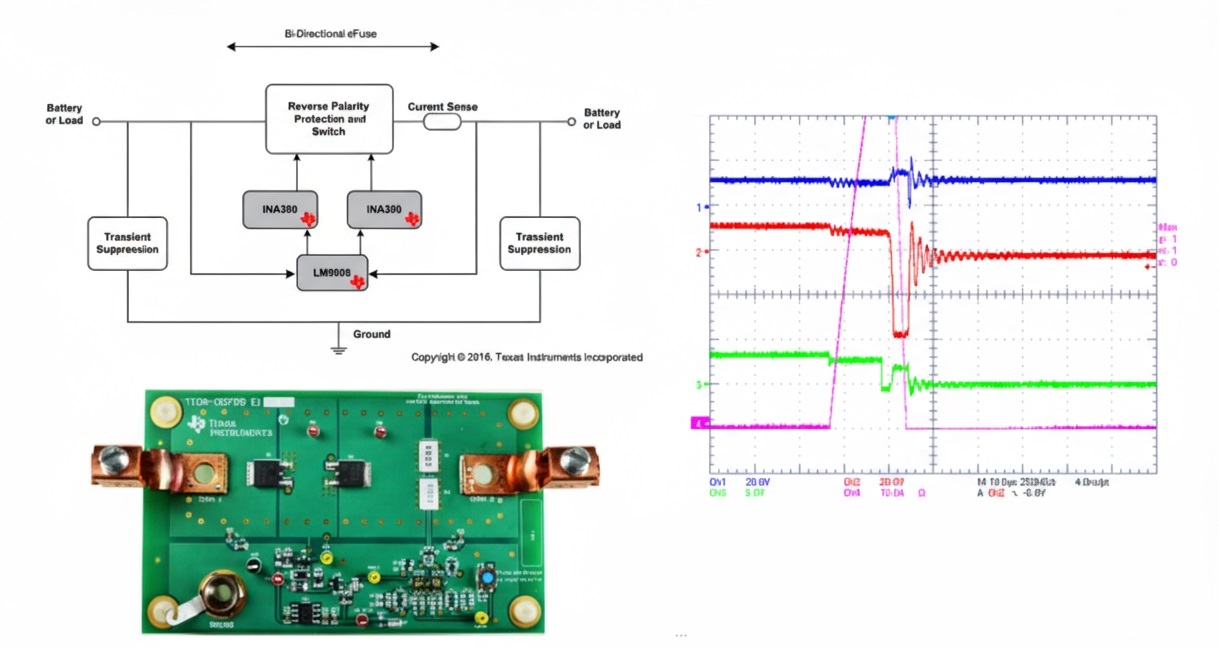

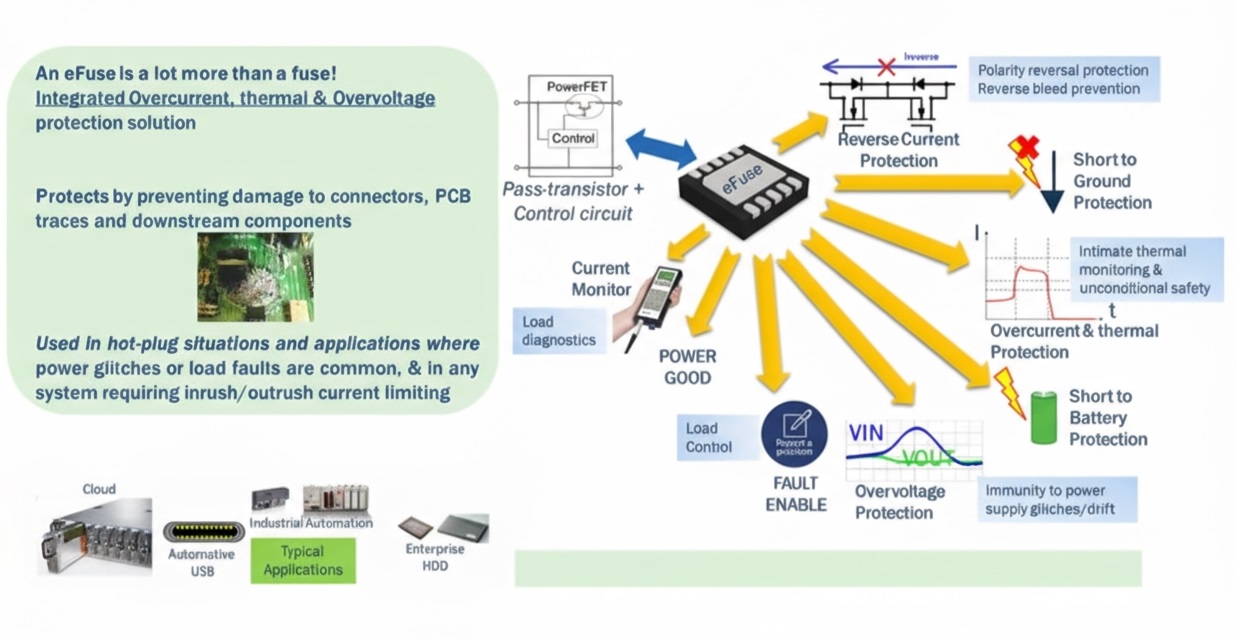

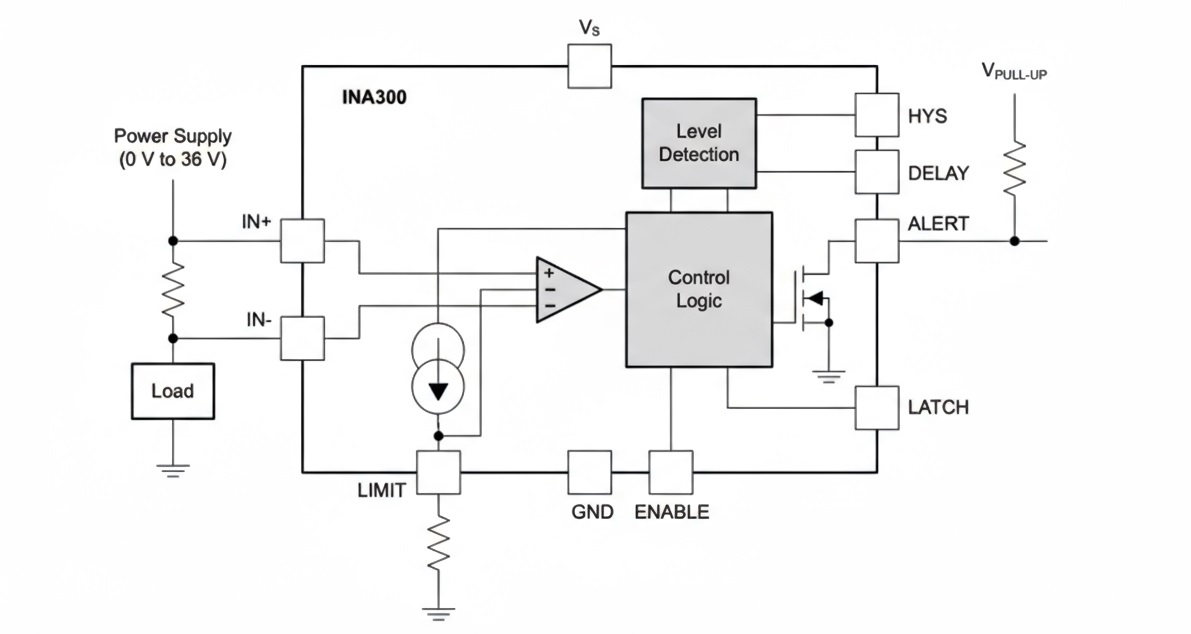

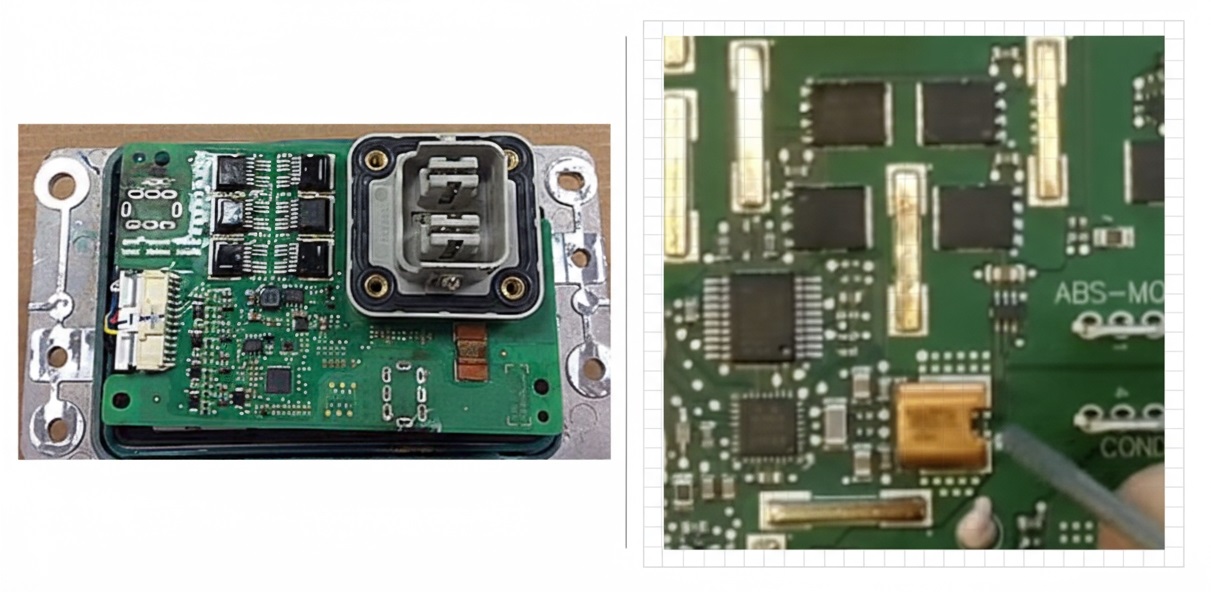

The operating principle of e-Fuse uses power semiconductors such as MOSFETs (or IGBTs) and a sensing resistor to monitor voltage and protect the circuit. It can be paired with a 16-bit MCU or similar controller to implement programmable control, monitoring, and diagnostic functions. When an overload or short circuit occurs, the e-Fuse quickly opens the current path to protect downstream circuits from damage.

Applications for e-Fuse span vehicle electrical systems, with particular relevance to autonomous driving, low-voltage system upgrades, and E/E architecture enhancements. e-Fuse performance meets increasingly stringent electrical safety requirements. e-Fuse can operate at very low single-digit voltages and low currents, while traditional thermal fuses often cannot function under such conditions because they rely on self-heating current to blow.

Traditional centralized power distribution delivers energy from the battery to multiple load systems, whereas intelligent distribution uses a distributed architecture that shortens harness loop lengths. The current-monitoring and turn-off characteristics of e-Fuse can reduce required wire gauge margins and help lower harness cost.

There are two main manufacturing approaches for e-Fuse: discrete and integrated solutions. Discrete implementations use multiple field-effect transistors, a resistor, and an inductor, while integrated circuit solutions consolidate some or all functions into a single chip. As connected and intelligent vehicles become more prevalent, performance and reliability requirements rise; integrated IC solutions are better positioned to meet these requirements and are expected to gain prominence in vehicle electrical systems.

Tesla and other manufacturers have begun adopting e-Fuse technology, and Chinese automakers are also following. Market forecasts indicate that the Chinese e-Fuse market will expand to the tens of billions of yuan range in the coming years, with continued long-term growth. Automotive electronics integrators are likely to become a principal force in this field, given their capability to co-develop vehicle architectures with OEMs.

Summary

e-Fuse is a key component for next-generation vehicle architecture circuit protection. Its faster protection, programmability, diagnostics, and adaptability to low-voltage and low-current scenarios position it to play an increasing role in future vehicle electrical systems.

ALLPCB

ALLPCB