Wearable temperature patches are an emerging trend for patient temperature monitoring. One major challenge in designing these patches for clinical use is meeting strict accuracy requirements.

The American Society for Testing and Materials (ASTM) specifies accuracy requirements for electronic patient thermometers, as shown in Table 1. In the strictest range, these standards allow up to ±0.1°C error to ensure accurate measurement of patient body temperature.

Beyond selecting an accurate temperature sensor, achieving a true ±0.1°C accuracy in clinical probes or wearable temperature patches can be challenging for the following reasons:

- Low power: At this accuracy level, even transient power dissipation in the microwatt range can heat the sensor element and push measurements outside the ASTM E1112 limits.

- Thermal design: Even if the overall system has been calibrated and validated, external factors such as mechanical impact or changes in pressure can affect the sensor or measurement. Loss of contact with the skin alters the thermal path and reduces conductive coupling, degrading accuracy.

This article discusses basic design considerations when selecting sensing elements for wearable temperature monitoring systems to achieve accurate patient temperature measurements.

Choosing the Sensing Element

Before taking any measurement, select the right sensing element for the probe or patch. Common temperature monitoring sensor types include thermistors or integrated circuit (IC) temperature sensors. The chosen sensor must be reliable within the system and support consistent ±0.1°C accuracy across the device.

Thermistors offer a controllable balance between cost and power consumption but typically require calibration to reach medical-grade accuracy and can be susceptible to failure from impact or humidity changes. IC temperature sensors have recently become capable of ±0.1°C accuracy and offer additional advantages such as factory calibration, lower power consumption, and digital interfaces, which simplify system integration.

Designing for Minimal Temperature Error

Regardless of the sensing element selected, keep two key factors in mind when designing a patch with this level of precision:

- The sensor must be in thermal contact with the patient to ensure effective heat transfer.

- The sensor must be thermally isolated from all other heat sources.

1. Maintain Good Thermal Contact

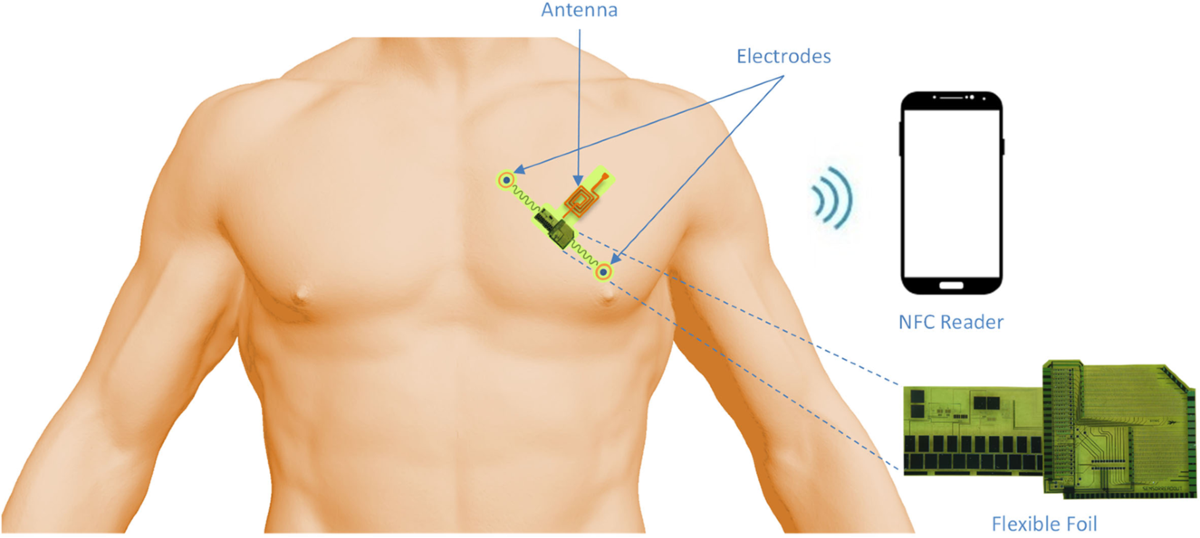

For external measurements with a temperature patch or skin probe, consider the actual thermal path between the sensing element and the user's skin. This IC temperature sensor measures the temperature of the silicon die. For such packages, it is best to place copper pours under the device thermal pads on both sides of the board. Connecting these pads with vias provides a conductive path between the die and the skin. Do not use exposed copper in direct contact with skin because of potential corrosion. Instead, use a biocompatible coating (for example, gold) or a coating at the contact points that interfaces with a thermally conductive polymer to provide reliable thermal conduction.

Wearable temperature sensing patches should use flexible or semi-rigid printed circuit board designs. In semi-rigid designs, place the sensing element on the bend side of the PCB and minimize the flex board thickness as much as possible. This reduces thermal resistance between the skin surface and the sensor; thinner boards bend more easily and make better contact.

The patch is designed to be worn with transparent adhesive tape to prevent the sensor and contact pad from lifting off the skin and degrading measurement accuracy. Some newer patch designs print the circuitry directly onto adhesive tape, producing an extremely thin profile that conforms well to the patient's body.

2. Thermally Isolate from Other Heat Sources

If the skin is intended to be the true thermal source for the sensing element, other heat sources must be removed. All electronic components dissipate some heat - generally, more electrical power corresponds to more heat - so place higher-power components as far from the sensing element as possible.

For body-temperature monitoring systems, this type of heating is difficult to compensate and can be hazardous to the patient. When designing temperature monitoring solutions, consider power-hungry components and place them away from the sensing unit to minimize their impact on sensor data.

Conclusion

Achieving medical-grade accuracy in patient temperature monitoring presents thermal challenges. Using the right sensor and applying careful layout and mechanical design practices can overcome these challenges and deliver accurate temperature measurements.

ALLPCB

ALLPCB