In the fast-paced world of electronics manufacturing, ensuring the quality and reliability of printed circuit boards (PCBs) is crucial. One of the most effective methods for achieving this is Flying Probe Testing (FPT). But what exactly is the flying probe testing process, and how can it benefit manufacturers? In this comprehensive guide, we’ll break down flying probe testing explained in simple terms, explore its applications, and provide a detailed FPT guide to help you understand its role in modern PCB production. Whether you’re new to the concept or seeking to optimize your testing process, this article will provide actionable insights tailored for electronics manufacturers.

What Is Flying Probe Testing? A Quick Overview

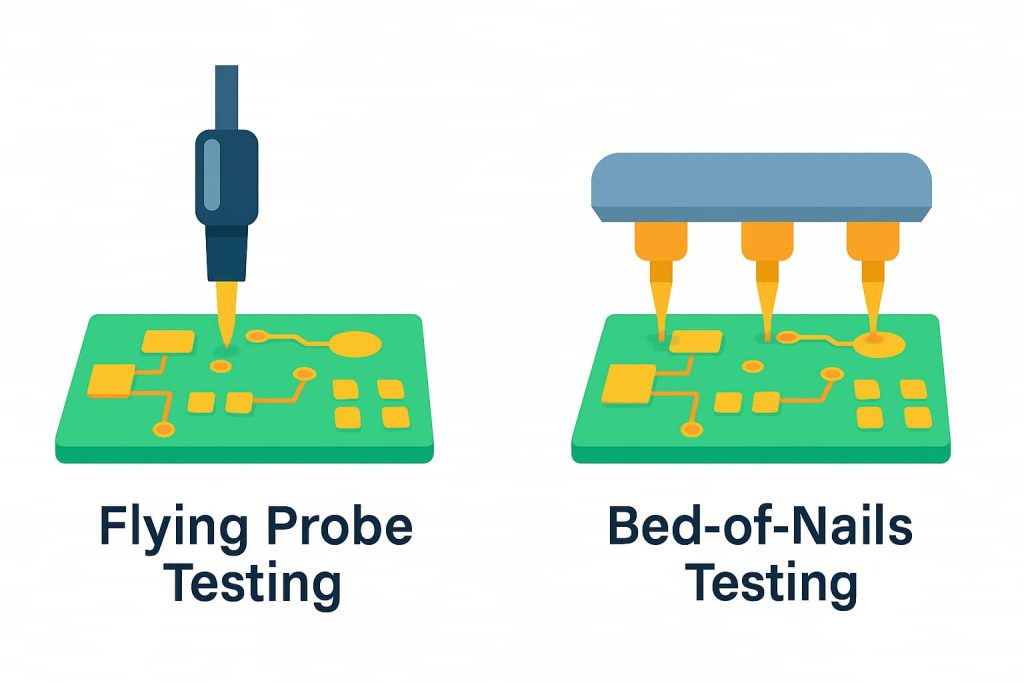

Flying Probe Testing, often abbreviated as FPT, is a fixtureless in-circuit testing method used to evaluate the electrical functionality of PCBs. Unlike traditional testing methods that require custom fixtures like a bed of nails, FPT uses movable test probes that “fly” across the board to make contact with specific test points. This flexibility makes it an ideal choice for prototype development, low-volume production, and complex board designs where creating a dedicated test fixture would be costly or impractical.

In the sections below, we’ll dive deeper into the flying probe testing process, its advantages, limitations, and real-world applications to give you a complete understanding of this innovative technology.

Understanding the Flying Probe Testing Process

The flying probe testing process is a systematic approach to verifying the integrity of a PCB without the need for physical test fixtures. Here’s how it works, step by step:

- Programming the Test System: The process begins with programming the flying probe tester using the PCB’s design data, such as Gerber files or netlists. This data tells the machine where to position the probes and what electrical characteristics to measure (e.g., continuity, resistance, or capacitance).

- Positioning the PCB: The PCB is securely placed on the testing platform. Since no fixture is required, setup time is minimal compared to traditional methods.

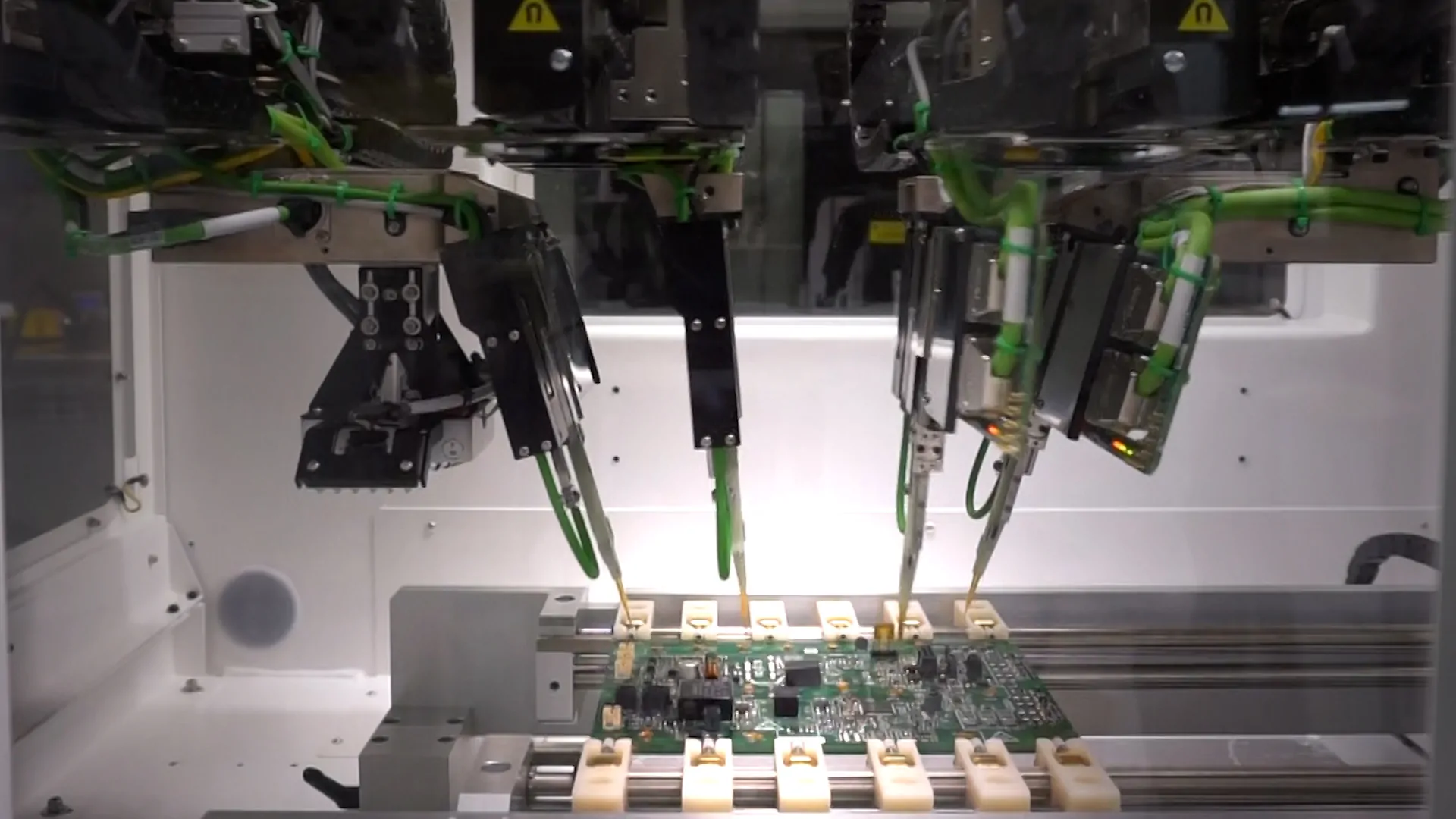

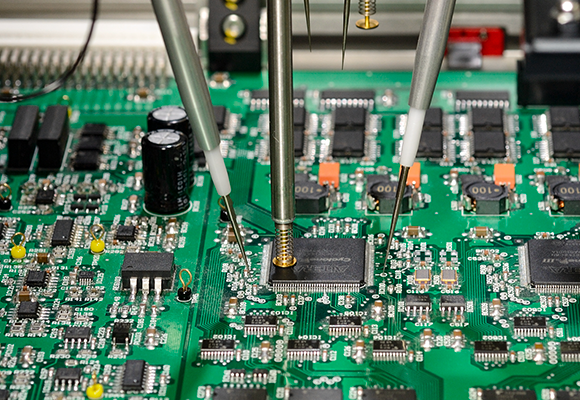

- Probe Movement and Testing: Multiple test probes, typically ranging from 2 to 8 depending on the machine, move precisely to designated test points on the PCB. These probes check for open circuits, short circuits, and component values like resistance or capacitance. For instance, a typical test might measure resistance values between 1 ohm and 10 megaohms to ensure connections are within spec.

- Data Collection and Analysis: As the probes make contact, the system collects data and compares it against expected values. Any deviations, such as a short circuit or an incorrect impedance value (e.g., measuring 75 ohms when 50 ohms is expected), are flagged as defects.

- Reporting Results: Once testing is complete, a detailed report is generated, highlighting any issues found. This allows manufacturers to address problems before moving to the next production stage.

The precision of modern flying probe systems is remarkable. Many machines can achieve positioning accuracy within 5 micrometers, ensuring even the smallest test points on densely populated boards are accessible. This level of detail is critical for high-density interconnect (HDI) boards, where test points may be as close as 0.2 mm apart.

Advantages of Flying Probe Testing Explained

Flying probe testing offers several benefits that make it a popular choice among electronics manufacturers. Let’s explore why this method stands out:

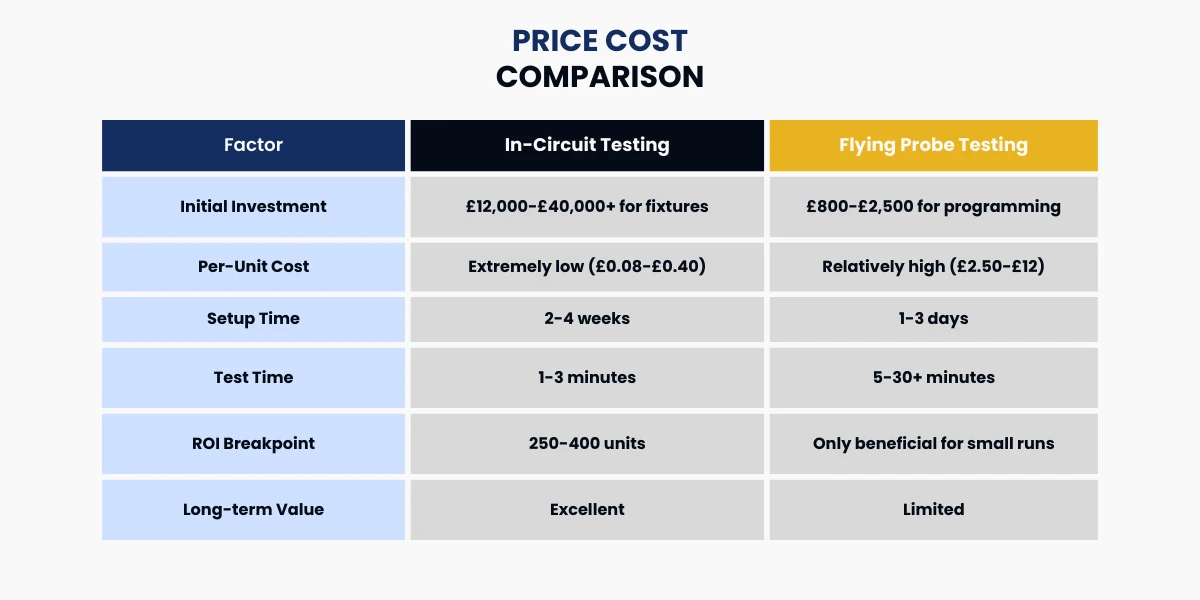

- Fixtureless Design: Since FPT doesn’t require custom test fixtures, it eliminates the upfront cost and lead time associated with designing and building a bed of nails setup. This can save thousands of dollars, especially for small runs or prototypes.

- Flexibility: The ability to reprogram the tester for different PCB designs makes FPT highly adaptable. Whether you’re testing a simple single-layer board or a complex multi-layer design, the system can handle it with minimal setup changes.

- High Accuracy: Flying probe testers can detect minute defects, such as a 1-megaohm leakage path that might go unnoticed in less precise methods. This ensures high reliability in the final product.

- Ideal for Prototypes and Low-Volume Production: For batches of fewer than 100 units, FPT is often more cost-effective than traditional testing, as there’s no need to invest in expensive fixtures.

- Access to Dense Boards: With probes capable of reaching test points as small as 0.1 mm, FPT excels in testing modern, high-density PCB designs where space is at a premium.

However, it’s worth noting that FPT may not be the fastest option for high-volume production. The sequential nature of probe movement means testing a single board can take longer—sometimes up to 10 minutes for a complex design—compared to a bed of nails tester that contacts multiple points simultaneously.

Limitations of Flying Probe Testing

While flying probe testing has many strengths, it’s not without its challenges. Understanding these limitations can help manufacturers decide when FPT is the right choice:

- Slower Test Speeds: As mentioned earlier, the time it takes for probes to move between test points can slow down the process. For high-volume runs of identical boards, a bed of nails tester might complete testing in under 30 seconds per board, while FPT could take several minutes.

- Limited Component Testing: While FPT excels at checking for shorts and opens, it may struggle with functional testing of complex components like microcontrollers or high-speed digital circuits operating at signal speeds above 1 GHz.

- Initial Setup Complexity: Programming the tester requires detailed design data and expertise. Errors in the netlist or Gerber files can lead to inaccurate testing, necessitating careful validation upfront.

Flying Probe Testing Applications in Electronics Manufacturing

The versatility of flying probe testing makes it suitable for a wide range of applications in the electronics industry. Below are some key areas where FPT shines:

1. Prototype Development

During the early stages of product design, manufacturers often produce small batches of PCBs to validate functionality. Flying probe testing is perfect here because it eliminates the need for costly fixtures while providing detailed feedback on potential design flaws. For example, if a prototype board shows an unexpected impedance of 100 ohms on a critical signal line instead of the designed 50 ohms, FPT can pinpoint the issue for correction.

2. Low-Volume Production

For small production runs, such as custom industrial control boards or specialized medical devices, FPT offers a cost-effective testing solution. It allows manufacturers to ensure quality without the overhead of fixture development, which might cost upwards of $5,000 for a single design.

3. High-Density and Complex Boards

Modern electronics often feature densely packed components with fine-pitch test points. Flying probe testers, with their precision movement and small probe tips (down to 0.1 mm), can access these points to verify connections and component values, making them indispensable for HDI and multi-layer PCBs.

4. Repair and Debugging

Beyond initial testing, FPT is also used in repair scenarios. If a board fails in the field, a flying probe tester can be programmed to isolate faults, such as a broken trace or a failed capacitor with a measured value of 0.5 microfarads instead of the expected 1 microfarad, helping technicians address issues quickly.

5. Niche and Specialty Products

For industries like aerospace or automotive, where safety and reliability are paramount, FPT provides the detailed testing needed for small batches of highly specialized boards. These sectors often require testing for specific electrical characteristics, such as insulation resistance above 10 megaohms, which FPT can measure with precision.

An FPT Guide: Best Practices for Electronics Manufacturers

To get the most out of flying probe testing, manufacturers should follow these best practices as part of their FPT guide:

- Optimize Design Data: Ensure that your Gerber files and netlists are accurate and up-to-date before programming the tester. Errors in this data can lead to false positives or missed defects. Double-check test point coordinates to avoid probe misalignment.

- Define Clear Test Parameters: Specify the electrical characteristics to be tested, such as resistance ranges (e.g., 1 ohm to 1 megaohm) or capacitance thresholds (e.g., 1 pF to 100 nF). This ensures the system focuses on critical areas of the board.

- Prioritize Test Point Accessibility: During PCB design, place test points in locations that probes can easily reach. Avoid placing them under large components or in areas with limited clearance, as this can slow down testing or reduce accuracy.

- Combine with Other Testing Methods: For high-volume production, consider using FPT for initial validation and then switching to a faster method like bed of nails for mass testing. Alternatively, use FPT alongside functional testing to cover both electrical and operational checks.

- Regularly Calibrate Equipment: Flying probe testers rely on precision movement. Regular calibration ensures probes maintain accuracy within 5 micrometers, preventing errors during testing.

Comparing Flying Probe Testing to Other Methods

To fully appreciate the value of FPT, it’s helpful to compare it to other common PCB testing methods:

- FPT vs. Bed of Nails Testing: While bed of nails is faster for high-volume runs (testing up to 100 points simultaneously), it requires custom fixtures costing $2,000 to $10,000 per design. FPT, on the other hand, is fixtureless and better suited for low-volume or prototype testing.

- FPT vs. Automated Optical Inspection (AOI): AOI focuses on visual defects like misaligned components or solder issues but can’t test electrical functionality. FPT complements AOI by verifying electrical integrity, such as detecting an open circuit with infinite resistance.

- FPT vs. Functional Testing: Functional testing evaluates a board’s performance under real-world conditions but often requires complex setups. FPT is simpler and focuses on basic electrical checks, making it a cost-effective first step before functional testing.

Future Trends in Flying Probe Testing

As electronics manufacturing continues to evolve, so does flying probe testing technology. Here are some trends to watch:

- Increased Speed: Manufacturers are developing faster probe movement systems to reduce test times, making FPT more viable for medium-volume production. Some newer systems can test a board in under 2 minutes, compared to 5-10 minutes for older models.

- Enhanced Component Testing: Advances in probe technology are enabling FPT to test more complex components, such as high-speed digital signals up to 2 GHz, expanding its scope beyond basic electrical checks.

- Integration with AI: Artificial intelligence is being integrated into FPT systems to predict potential failure points based on historical data, improving defect detection rates by up to 20% in some cases.

Conclusion: Why Flying Probe Testing Matters for Your Business

Flying probe testing is a game-changer for electronics manufacturers, offering a flexible, accurate, and cost-effective way to ensure PCB quality. From the detailed flying probe testing process to its wide-ranging applications in prototype and low-volume production, FPT provides a practical solution for modern manufacturing challenges. By following this FPT guide, you can optimize your testing workflow, reduce costs, and deliver reliable products to your customers.

Whether you’re dealing with high-density boards, specialty designs, or early-stage prototypes, understanding flying probe testing explained in this comprehensive guide equips you with the knowledge to make informed decisions. As technology advances, staying ahead of the curve with methods like FPT will keep your manufacturing process competitive and efficient.

ALLPCB

ALLPCB