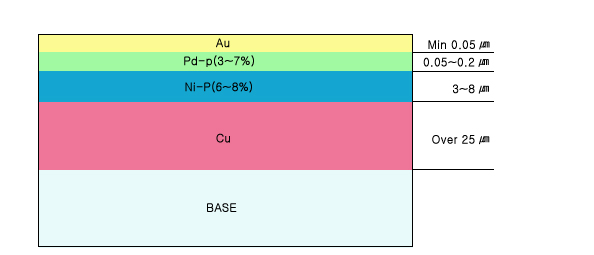

ENEPIG is suitable for soldering, gold wire bonding, aluminum wire bonding and contact resistance. It is formed by the sequential deposition of electroless Ni (120 to 240 micro inches) followed by 2 to 10 micro inches of electroless Palladium with an immersion gold flash of 2 to 6 micro inches on the top.

What is ENEPIG?

ENEPIG or Electroless Nickel - Electroless Palladium - Immersion Gold is a surface finish for Printed Circuit Boards that has been around for a decade but is only recently coming back into vogue. The high price of palladium had kept it out of reach for most businesses. With the price of palladium now less than the price of gold, this surface finish becomes the best choice for wire bonding, ROHS assembly and just all boards overall. ENEPIG works well with lead free and conventional eutectic solder alloys (Eutectic means its 63% tin and 37% lead.) ENEPIG is called the "Universal" surface finish as it can be used for all assembly processes.

What are the advantages of ENEPIG finish?

1. Excellent ROHS lead free and leaded solderability

Because palladium completely dissolves into the solder leaving an oxide free nickel surface which allows a reliable tin nickel inter metallic.

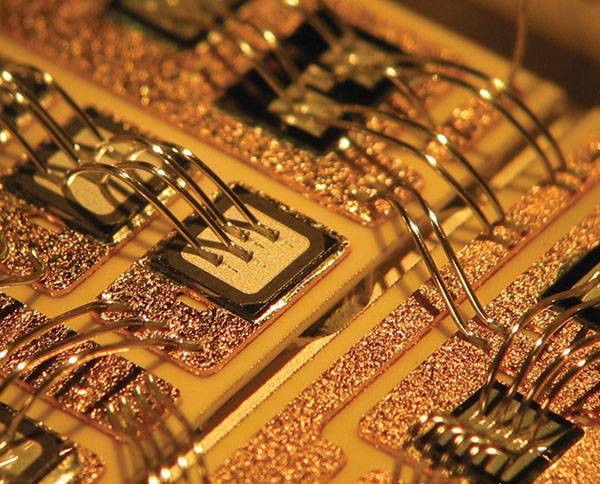

2. High wire bond pull strengths (aluminum wire: up to 10g; gold wire: up to 8g).

After numerous tests, it holds high pull weights.

Good for aluminum wedge and gold ball bonding

3. Low contact resistance

Due to the controlled deposition of precious metals the electrical resistance is more uniform so it's easier to predict amperage.

4. Suitable for conductive adhesives

You can connect components without the use of solder.

5. Finish is corrosion resistant and pore-free

Multiple layers of metal provide a higher corrosion resistant coating.

6. Unlimited shelf life

Doesn't tarnish

7. Nickel acts a barrier layer to further reduce copper dissolution during wave solder, thus ensuring good solderability.

Nickel prevents the mixing of copper and solder.

ENEPIG delivers great solder joint strength with various alloys during multiple reflow soldering, especially SAC305. The middle palladium layer helps to stabilize and control the inner metallic layer. Because of the mixture, ENEPIG after testing showed amazing wire bonding, both with aluminum and gold.

My Message

My Message

Suggestions

Suggestions

Brook

2/2/2017 7:56:56 PM

I am a new beginner and looking for good info for study. The posted info is pretty good. I will share it with my friends.