In the world of electronics manufacturing, sustainability is no longer just a trend—it's a necessity. If you're searching for eco-friendly solutions like lead-free solder PCB options, recyclable solder, or green soldering materials, you're in the right place. This blog dives deep into the shift toward RoHS compliant solder and sustainable soldering practices, offering practical insights for engineers and manufacturers looking to build greener printed circuit boards (PCBs).

Whether you're aiming to meet environmental regulations or reduce your carbon footprint, we'll cover everything from the benefits of lead-free alternatives to the latest advancements in recyclable materials. Let's explore how you can make a positive impact with your soldering choices.

Why Green Soldering Matters in PCB Manufacturing

The electronics industry has a significant environmental impact, from resource extraction to waste generation. Traditional soldering methods often rely on lead-based materials, which pose health risks and environmental hazards. Lead can contaminate soil and water, affecting ecosystems and human health over time. This is why regulations like the Restriction of Hazardous Substances (RoHS) directive have pushed for safer, more sustainable practices.

Green soldering focuses on using materials and processes that minimize harm. By adopting lead-free solder PCB solutions and exploring recyclable solder options, manufacturers can comply with global standards while contributing to a cleaner planet. Beyond compliance, sustainable soldering also appeals to environmentally conscious consumers and businesses, giving companies a competitive edge.

Understanding Lead-Free Solder for PCBs

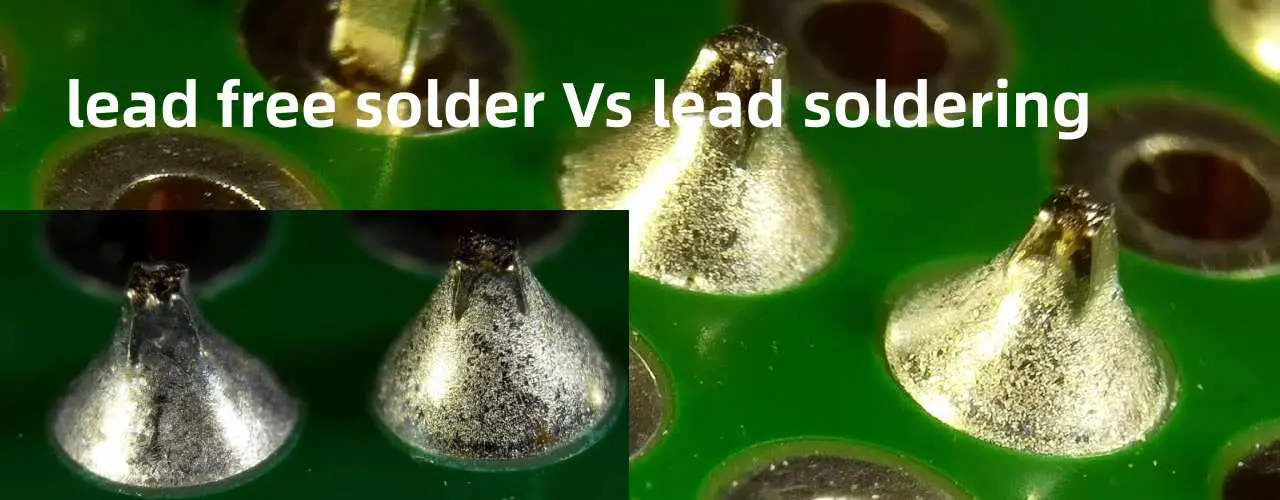

Lead-free solder PCB solutions have become the standard in electronics manufacturing since the RoHS directive came into effect in 2006. Unlike traditional tin-lead solder, which typically contains 60-63% tin and 37-40% lead, lead-free alternatives use combinations of tin, silver, copper, and other metals. These materials aim to replicate the performance of lead-based solder while eliminating toxic risks.

Common lead-free solder alloys include:

- SAC (Tin-Silver-Copper): Often SAC305 (96.5% tin, 3% silver, 0.5% copper), this alloy is widely used due to its good mechanical strength and thermal reliability. It has a melting point of around 217-220°C, slightly higher than traditional tin-lead solder (183°C).

- Sn-Cu (Tin-Copper): A cost-effective option with a higher melting point of about 227°C, often used in wave soldering processes.

- Sn-Bi (Tin-Bismuth): With a lower melting point of around 138°C, this alloy is suitable for temperature-sensitive components but less common due to brittleness concerns.

The transition to lead-free solder hasn't been without challenges. Higher melting points require adjustments in soldering equipment and processes to avoid damaging components. However, advancements in technology have made lead-free soldering more accessible and reliable for modern PCB assembly.

The Benefits of Lead-Free Solder in Sustainable Soldering

Switching to lead-free solder PCB options offers several advantages for both manufacturers and the environment. Here are some key benefits:

- Environmental Safety: Lead-free solder reduces the risk of toxic contamination during manufacturing, use, and disposal of electronic devices.

- Regulatory Compliance: Using RoHS compliant solder ensures that products meet strict environmental standards in regions like the European Union, avoiding potential fines or market restrictions.

- Improved Public Image: Companies that prioritize sustainable soldering practices can build trust with eco-conscious customers and partners.

- Worker Safety: Eliminating lead exposure during soldering protects workers from health risks like neurological damage or respiratory issues.

While the initial cost of transitioning to lead-free materials may be higher due to equipment upgrades or material expenses, the long-term benefits in terms of compliance and sustainability far outweigh these challenges.

Exploring Recyclable Solder Materials for PCBs

Beyond lead-free options, the industry is also focusing on recyclable solder to further enhance sustainability. Traditional solder materials are often difficult to recover and reuse due to contamination or degradation during the soldering process. However, innovations in green soldering materials are changing the game.

Recyclable solder aims to create a closed-loop system where materials can be reclaimed and reused without significant loss of quality. For instance, some manufacturers are developing solder alloys with improved separability, allowing them to be extracted from PCBs during recycling processes. Research is also underway to create solders that can be broken down and reformed with minimal energy input.

One promising area is the use of biodegradable or low-impact additives in solder formulations. These materials reduce the environmental footprint of solder waste and make it easier to process discarded electronics. While fully recyclable solder is still in the early stages of adoption, it represents a critical step toward a circular economy in electronics manufacturing.

RoHS Compliant Solder: Meeting Global Standards

The push for RoHS compliant solder stems from the need to restrict hazardous substances in electronics. The RoHS directive, first implemented in the EU, limits the use of six harmful materials, including lead, mercury, and cadmium, in electrical and electronic equipment. For PCB manufacturers, this means adopting lead-free solder and ensuring that all components meet these standards.

Compliance with RoHS isn't just about avoiding penalties—it's also about accessing global markets. Many countries outside the EU have adopted similar regulations, and non-compliant products can be barred from entry. By using RoHS compliant solder, manufacturers can ensure their products are marketable worldwide.

To achieve compliance, it's essential to work with suppliers who provide certified lead-free materials and to implement strict quality control measures during assembly. Regular testing for restricted substances can also prevent accidental non-compliance due to contaminated materials.

Challenges in Adopting Green Soldering Materials

While the benefits of green soldering materials are clear, there are hurdles to overcome. Let's look at some common challenges and how to address them:

- Higher Costs: Lead-free and recyclable solders often come with a higher price tag due to raw material costs and the need for specialized equipment. However, bulk purchasing and long-term partnerships with suppliers can help manage expenses.

- Performance Differences: Lead-free solders may have different wetting properties or mechanical strength compared to traditional solders. Adjusting soldering profiles and using compatible fluxes can mitigate these issues.

- Process Adaptation: Higher melting points of lead-free alloys require recalibration of reflow ovens and soldering irons. Investing in training for technicians ensures a smooth transition.

- Limited Availability of Recyclable Options: Fully recyclable solder is not yet widely available, but staying updated on industry innovations can help manufacturers adopt these solutions as they emerge.

Despite these challenges, the industry is moving steadily toward greener practices, with continuous improvements in materials and technologies.

Practical Tips for Implementing Sustainable Soldering

For engineers and manufacturers looking to adopt sustainable soldering practices, here are some actionable steps to get started:

- Choose the Right Alloy: Select a lead-free solder alloy that matches your application needs. For high-reliability products, SAC305 is often a safe choice due to its proven performance.

- Optimize Soldering Profiles: Adjust temperature and time settings in your reflow or wave soldering process to accommodate the higher melting points of lead-free solders, typically between 217-227°C.

- Partner with Certified Suppliers: Source materials from suppliers who provide documentation for RoHS compliant solder to ensure regulatory adherence.

- Invest in Training: Equip your team with the knowledge to handle lead-free and green materials effectively, minimizing defects like poor wetting or thermal damage.

- Monitor Industry Trends: Keep an eye on advancements in recyclable solder and other green soldering materials to stay ahead of the curve.

Future of Green Soldering in Electronics Manufacturing

The future of sustainable soldering looks promising as technology and environmental awareness continue to evolve. Researchers are exploring innovative alloys that not only eliminate hazardous substances but also improve performance metrics like thermal conductivity and durability. Additionally, the development of fully recyclable solder systems could revolutionize how we handle electronic waste, reducing landfill contributions significantly.

Automation and AI are also playing a role in optimizing soldering processes for sustainability. Smart soldering equipment can adjust parameters in real-time to minimize energy use and material waste, further supporting green initiatives.

As regulations become stricter and consumer demand for eco-friendly products grows, adopting lead-free solder PCB solutions and other sustainable practices will be essential for staying competitive. Manufacturers who invest in green soldering today are positioning themselves as leaders in tomorrow's electronics industry.

Conclusion: Building a Greener Future with Sustainable Soldering

Green soldering is more than just a regulatory requirement—it's a commitment to a healthier planet and safer working conditions. By embracing lead-free solder PCB options, exploring recyclable solder innovations, and using RoHS compliant solder, manufacturers can reduce their environmental impact while meeting global standards. The journey toward sustainable soldering may come with challenges, but the rewards in terms of compliance, safety, and marketability make it a worthwhile investment.

At every stage of PCB manufacturing, from design to assembly, choosing green soldering materials can make a difference. Start small by testing lead-free alloys in your next project, and stay informed about emerging technologies that support sustainability. Together, we can build an electronics industry that prioritizes both performance and the planet.

ALLPCB

ALLPCB