In the fast-paced world of logistics, warehouse automation is transforming how goods are stored, moved, and delivered. At the heart of this revolution are Printed Circuit Boards (PCBs) designed specifically for automation systems. These tiny yet powerful components power everything from automated storage and retrieval systems to robotics and automated guided vehicles (AGVs). In this blog, we’ll explore how PCBs are redefining logistics, diving into key areas like automated storage and retrieval system PCB design, warehouse robotics PCB manufacturing, PCB for AGV power management, PCB design considerations for warehouse environmental conditions, and PCB testing standards for warehouse equipment.

What Are Warehouse Automation PCBs and Why Do They Matter?

Warehouse automation PCBs are specialized circuit boards that control and manage the electronic functions of automated systems in logistics environments. These boards are the brains behind robots, conveyor systems, AGVs, and storage units, ensuring seamless operation, precision, and efficiency. With the global e-commerce market booming and the demand for faster delivery growing, businesses rely on automation to keep up. PCBs enable this by providing reliable, high-performance control for complex machinery, cutting down on human error and operational costs.

In the sections below, we’ll break down the critical role of PCBs in various automation technologies and offer insights into their design, manufacturing, and testing processes. Whether you’re an engineer, logistics manager, or tech enthusiast, this guide will help you understand how these components are shaping the future of warehousing.

Automated Storage and Retrieval System PCB Design: Precision at Scale

Automated Storage and Retrieval Systems (AS/RS) are a cornerstone of modern warehouses, enabling high-density storage and rapid retrieval of goods. These systems rely heavily on PCBs to control mechanical arms, conveyor belts, and sensors that locate and move inventory. Designing PCBs for AS/RS requires a focus on precision and reliability since even a small error can lead to costly downtime or inventory mismanagement.

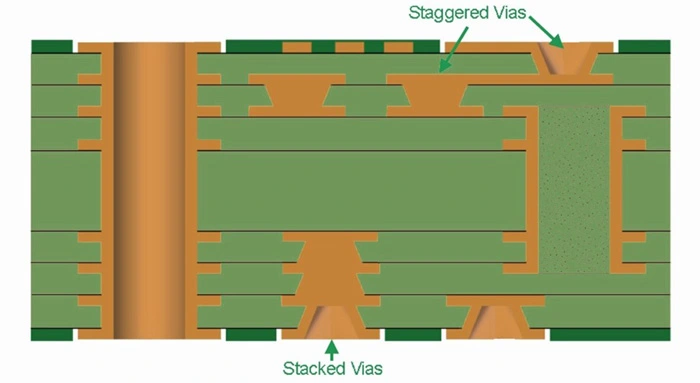

Key considerations in AS/RS PCB design include high-speed signal integrity to ensure fast communication between components. For instance, signal speeds often need to exceed 1 GHz to handle real-time data from sensors and actuators. Additionally, impedance control is critical, with typical values ranging from 50 to 100 ohms to prevent signal loss or interference. Designers also prioritize compact layouts to fit within the limited space of robotic units, often using multi-layer boards to accommodate complex circuits.

Thermal management is another crucial factor. AS/RS systems often operate continuously, generating heat that can degrade PCB performance. Using materials with high thermal conductivity and incorporating heat sinks or vias can help dissipate heat effectively. By addressing these challenges, PCBs ensure that AS/RS systems run smoothly, boosting warehouse throughput by up to 30% in some cases.

Warehouse Robotics PCB Manufacturing: Building the Future of Automation

Warehouse robotics, such as picking robots and sorting machines, are transforming manual tasks into automated processes. The PCBs that power these robots must be manufactured with exceptional durability and precision to withstand constant movement and heavy workloads. Warehouse robotics PCB manufacturing involves several key steps to meet these demands.

First, material selection is critical. High-quality FR-4 or advanced laminates are often used for their strength and resistance to vibration, which is common in robotic applications. The manufacturing process also emphasizes tight tolerances, with trace widths and spacing as small as 0.1 mm to support high-density designs. Surface finishes like ENIG (Electroless Nickel Immersion Gold) are applied to protect against corrosion and ensure reliable soldering of components.

Another focus is on scalability. As warehouses expand automation, manufacturers must produce PCBs in large volumes without compromising quality. Advanced fabrication techniques, such as automated optical inspection (AOI), help detect defects early, ensuring each board meets stringent performance standards. These manufacturing practices result in PCBs that enable robots to operate with 99.9% uptime, a critical factor in meeting tight delivery schedules.

PCB for AGV Power Management: Driving Efficiency on the Move

Automated Guided Vehicles (AGVs) are mobile robots that transport goods within warehouses, and their performance depends heavily on efficient power management. PCBs designed for AGV power management play a vital role in regulating voltage, managing battery life, and ensuring uninterrupted operation. Without well-designed power circuits, AGVs can suffer from frequent downtime or reduced efficiency.

AGV power management PCBs often incorporate DC-DC converters to step down or step up voltage levels, typically ranging from 12V to 48V, depending on the vehicle’s requirements. These boards also include overcurrent and overvoltage protection circuits to safeguard against power surges, which could otherwise damage sensitive components. For instance, a typical current limit might be set at 10A to prevent overheating during peak loads.

Battery monitoring is another critical function. PCBs integrate circuits to track battery health and optimize charging cycles, extending operational time by up to 20%. Designers must also account for electromagnetic interference (EMI), using shielding and proper grounding to minimize noise that could disrupt navigation systems. With robust power management PCBs, AGVs can navigate complex warehouse layouts with precision, reducing transport times significantly.

PCB Design Considerations for Warehouse Environmental Conditions: Built to Last

Warehouses are challenging environments for electronic components. Temperature fluctuations, humidity, dust, and vibrations can all impact PCB performance if not addressed during the design phase. PCB design considerations for warehouse environmental conditions are essential to ensure long-term reliability and prevent costly failures.

Temperature is a primary concern, as warehouses may range from freezing cold in refrigerated areas (as low as -20°C) to hot conditions near machinery (up to 50°C). PCBs must use materials with wide thermal tolerance and incorporate thermal vias to manage heat dissipation. Humidity, often reaching 80% in some facilities, can cause corrosion or short circuits. Designers combat this by applying conformal coatings to protect against moisture and using sealed connectors.

Dust and debris are also common in warehouses, potentially clogging components or causing electrical faults. Enclosures or protective layers on PCBs help mitigate these risks. Finally, vibrations from machinery or AGV movement require robust mounting and flexible materials to prevent cracking. By addressing these environmental factors, PCBs can achieve lifespans of 5-10 years even in harsh conditions, minimizing maintenance costs for logistics companies.

PCB Testing Standards for Warehouse Equipment: Ensuring Reliability

Reliability is non-negotiable for warehouse automation equipment, where downtime can cost thousands of dollars per hour. PCB testing standards for warehouse equipment are rigorous to ensure that every board performs flawlessly under real-world conditions. These standards cover electrical performance, environmental resilience, and mechanical durability.

Electrical testing often includes in-circuit testing (ICT) to verify component functionality and signal integrity. For example, boards are tested for continuity and resistance, ensuring values stay within specified ranges like 1-10 milliohms for critical connections. Functional testing simulates real-world operations, such as running an AGV control PCB through a full duty cycle to check for errors.

Environmental testing mimics warehouse conditions, exposing PCBs to temperature cycles between -40°C and 85°C, humidity levels up to 95%, and vibration frequencies of 10-500 Hz. Standards like IPC-6012 (for rigid PCBs) and MIL-STD-810 (for environmental testing) provide guidelines to ensure consistency. Mechanical stress tests assess durability against shocks and drops, critical for boards in mobile equipment like AGVs. Adhering to these testing standards ensures that PCBs maintain 99.99% reliability, keeping warehouse operations running smoothly.

The Bigger Picture: How PCBs Drive Logistics Efficiency

The integration of advanced PCBs into warehouse automation systems is more than just a technical upgrade; it’s a game-changer for logistics efficiency. With AS/RS systems powered by precise PCBs, warehouses can store up to 40% more inventory in the same space. Robotics equipped with durable boards handle repetitive tasks, reducing labor costs by as much as 25%. AGVs with optimized power management PCBs cut transport times, while designs tailored for harsh environments ensure minimal downtime.

Moreover, the data-driven nature of modern logistics relies on PCBs to enable real-time monitoring and decision-making. Sensors and communication modules on these boards collect data on inventory levels, equipment health, and operational efficiency, feeding into warehouse management systems for smarter planning. This connectivity is paving the way for fully autonomous “dark warehouses” that operate without human intervention, a trend gaining traction in the industry.

Why Partner with Experts for Warehouse Automation PCBs?

Designing and manufacturing PCBs for warehouse automation is a complex task that demands expertise in electronics, environmental engineering, and logistics workflows. Partnering with a trusted provider ensures that your PCBs meet the specific needs of your automation systems, from high-speed AS/RS units to rugged AGVs. A reliable partner offers end-to-end services, including custom design, high-quality manufacturing, and thorough testing to guarantee performance.

By leveraging advanced tools and industry knowledge, expert providers can help you navigate challenges like thermal management, EMI reduction, and environmental resilience. This collaboration results in PCBs that not only meet current demands but also scale with future innovations in warehouse automation, keeping your logistics operations ahead of the curve.

Conclusion: The Future of Logistics Lies in PCB Innovation

Warehouse automation PCBs are the silent heroes of the logistics revolution, powering the systems that keep goods moving efficiently across the globe. From automated storage and retrieval system PCB design to warehouse robotics PCB manufacturing, these components are critical to achieving speed, accuracy, and cost savings. By focusing on areas like PCB for AGV power management, design considerations for warehouse environmental conditions, and strict PCB testing standards for warehouse equipment, businesses can unlock the full potential of automation.

As the logistics industry continues to evolve, staying at the forefront of PCB technology will be key to maintaining a competitive edge. Whether you’re optimizing an existing warehouse or building a fully automated facility, the right PCBs can make all the difference in redefining how you manage and deliver goods.

ALLPCB

ALLPCB