In the fast-evolving world of PCB design, buried resistors have emerged as a solution for creating compact, high-performance circuit boards. But what are the hidden costs and challenges of using buried resistors in PCB implementation? While they save space and improve signal integrity, buried resistors come with significant disadvantages, including design complexities, repair issues, testing difficulties, and higher costs. In this detailed guide, we’ll uncover the pitfalls of buried resistors and provide practical insights to help engineers navigate these challenges effectively.

What Are Buried Resistors and Why Use Them?

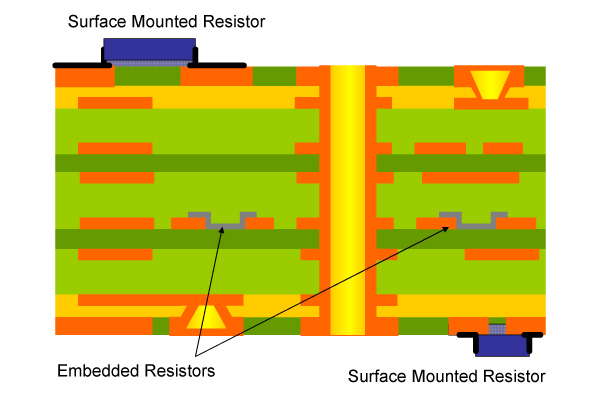

Buried resistors, also known as embedded resistors, are resistive elements integrated directly into the internal layers of a printed circuit board (PCB) during the manufacturing process. Unlike traditional surface-mounted resistors, they are not visible on the board’s exterior, which helps save valuable surface space for other components. This technology is often used in high-speed, high-density designs where minimizing signal interference and maximizing space are critical.

The primary benefits of buried resistors include reduced parasitic inductance (often below 1 nH compared to 2-3 nH in surface-mounted resistors), improved signal integrity at frequencies above 1 GHz, and a cleaner board layout. However, these advantages come at a price. Let’s dive into the hidden costs and challenges associated with buried resistors to help you make informed decisions for your next project.

Disadvantages of Buried Resistors: Why They’re Not Always the Best Choice

While buried resistors offer space-saving benefits, they introduce several disadvantages that can impact the overall success of a PCB project. Understanding these drawbacks is crucial for engineers looking to balance performance with practicality.

- Limited Flexibility: Once buried resistors are integrated into the PCB layers, their values cannot be changed without redesigning and remanufacturing the entire board. This lack of flexibility can be a major issue during prototyping or when design tweaks are needed.

- Higher Failure Risk: If a buried resistor fails, it’s nearly impossible to replace or repair without destroying the board. This contrasts with surface-mounted resistors, which can be desoldered and swapped out with ease.

- Thermal Management Issues: Buried resistors are enclosed within the PCB, making heat dissipation more challenging. Excessive heat buildup (sometimes reaching temperatures above 100°C in high-power applications) can degrade performance or damage surrounding layers.

These disadvantages highlight the importance of thorough planning before committing to buried resistors in your design. They may save space, but the trade-offs can be significant if not managed properly.

Buried Resistor Design Challenges: Navigating Complexities Early On

Designing a PCB with buried resistors requires precision and foresight. The process is far more complex than working with surface-mounted components, and several challenges can arise during the design phase.

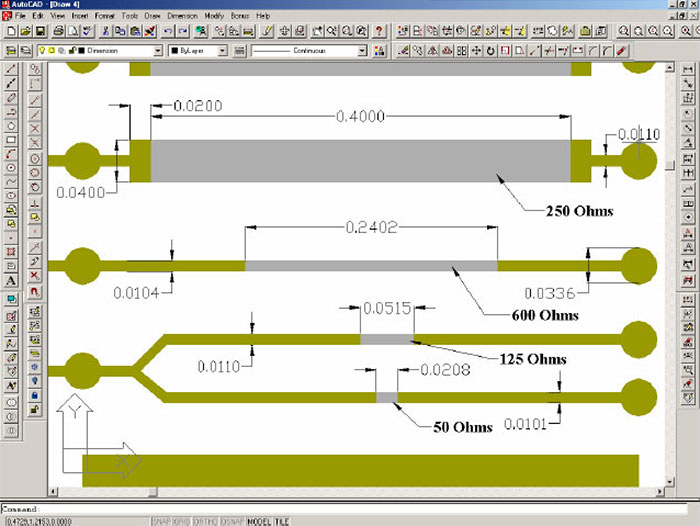

- Material Selection: Buried resistors are typically formed using specialized resistive materials, such as thin-film or thick-film pastes, with resistance values ranging from 10 ohms to 100 kOhms. Choosing the right material to achieve the desired resistance and tolerance (often ±10% or tighter) is critical and can limit design options.

- Layer Stack-Up Complexity: Embedding resistors within internal layers adds complexity to the PCB stack-up. Designers must ensure proper alignment and spacing to avoid interference with vias or other embedded components, which can increase design time by 20-30% compared to standard layouts.

- Signal Integrity Concerns: While buried resistors reduce parasitic effects, improper placement or sizing can still introduce noise or crosstalk, especially in high-frequency designs operating above 2 GHz. Extensive simulation and testing are often required to mitigate these risks.

To overcome these design challenges, engineers must invest in advanced design tools and collaborate closely with manufacturing teams to ensure compatibility between the design and fabrication processes.

Buried Resistor Repair Issues: The Cost of Inaccessibility

One of the most significant drawbacks of buried resistors is the difficulty of repairing or replacing them. Since they are embedded within the PCB, accessing a faulty resistor is a daunting task that often leads to costly consequences.

- No Direct Access: Unlike surface-mounted components, buried resistors cannot be accessed with standard soldering tools. Attempting to repair them may involve delaminating the PCB, which risks damaging other layers or components.

- High Replacement Costs: If a buried resistor fails, the only practical solution is often to scrap the entire board and manufacture a new one. For complex, multilayer boards costing upwards of $500 per unit in small batches, this can be a significant financial burden.

- Time Delays: Redesigning and remanufacturing a PCB can delay projects by weeks or even months, especially if the failure is discovered late in the testing or production phase.

For projects where reliability and ease of maintenance are priorities, engineers might consider alternative solutions, such as surface-mounted resistors or hybrid designs, to avoid the repair challenges associated with buried resistors.

Buried Resistor Testing Difficulties: Ensuring Reliability Without Direct Access

Testing buried resistors poses unique challenges due to their hidden nature. Ensuring their performance and reliability requires specialized techniques and equipment, adding to the overall project timeline and cost.

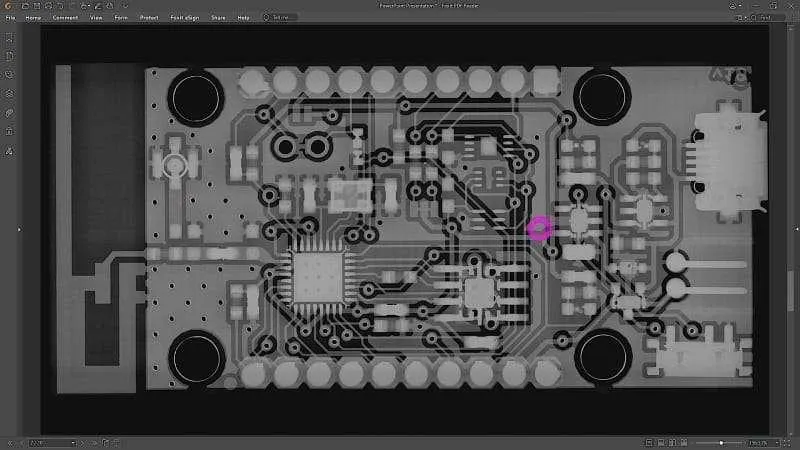

- Limited Testing Points: Since buried resistors are not exposed, direct probing with standard test equipment is impossible. Engineers must rely on indirect methods, such as measuring circuit behavior or using X-ray inspection, to assess resistor performance.

- Complex Fault Diagnosis: Identifying a faulty buried resistor often requires advanced diagnostic tools like thermal imaging or high-resolution X-rays, which can cost thousands of dollars in equipment and labor. Even then, pinpointing the exact issue can be time-consuming.

- Tolerance Verification: Buried resistors can have manufacturing variances in resistance values (sometimes deviating by ±5-10%). Verifying these tolerances without direct access adds another layer of complexity to quality control processes.

To mitigate testing difficulties, it’s essential to incorporate test structures or access points during the design phase. Working with experienced manufacturing partners who offer advanced testing capabilities can also help ensure the reliability of buried resistors.

Buried Resistor Cost Analysis: Weighing the Financial Impact

The financial implications of using buried resistors in PCB implementation are often underestimated. While they can reduce the need for surface components, the overall cost of design, manufacturing, and maintenance can outweigh the initial savings.

- Higher Manufacturing Costs: Embedding resistors requires specialized materials and processes, such as laser trimming for precise resistance values or additional lamination steps. These can increase manufacturing costs by 15-25% compared to standard PCB production.

- Design and Simulation Expenses: The complexity of buried resistor designs often necessitates advanced simulation software and extended design hours. For a mid-sized project, this can add $1,000-$5,000 in upfront costs.

- Yield and Scrap Losses: Manufacturing defects or resistor failures during production can lead to lower yields. With scrap rates sometimes reaching 10-15% for complex multilayer boards, the cost of wasted materials and rework can quickly add up.

- Long-Term Maintenance Costs: As discussed earlier, the inability to repair buried resistors means that failures often result in full board replacement, driving up long-term maintenance expenses.

For cost-sensitive projects, engineers should carefully evaluate whether the benefits of buried resistors justify the added expenses. In many cases, a hybrid approach—using a mix of buried and surface-mounted components—can strike a better balance between performance and cost.

Strategies to Mitigate the Pitfalls of Buried Resistors

While the challenges of buried resistors are significant, they can be managed with careful planning and strategic decision-making. Here are some practical tips to help engineers avoid common pitfalls:

- Thorough Prototyping: Invest in multiple prototype iterations to test the performance and reliability of buried resistors before moving to full-scale production. This can help identify issues early and reduce the risk of costly redesigns.

- Collaborate with Manufacturers: Work closely with your PCB fabrication team to ensure that the design aligns with their manufacturing capabilities. Early collaboration can prevent issues related to material compatibility or process limitations.

- Use Simulation Tools: Leverage advanced simulation software to model the behavior of buried resistors under various conditions. This can help optimize placement and minimize signal integrity issues before fabrication.

- Plan for Testing: Design the PCB with built-in test structures or access points to facilitate indirect testing of buried resistors. This can simplify quality control and fault diagnosis.

- Consider Alternatives: For applications where repairability or cost is a priority, evaluate whether surface-mounted resistors or other technologies can achieve similar results without the drawbacks of buried components.

By adopting these strategies, engineers can minimize the risks associated with buried resistors and ensure a smoother implementation process.

Conclusion: Making Informed Decisions About Buried Resistors

Buried resistors offer undeniable benefits for high-density, high-speed PCB designs, but their hidden costs and challenges cannot be ignored. From design complexities and repair issues to testing difficulties and increased expenses, the disadvantages of buried resistors can pose significant hurdles for engineers. By understanding these pitfalls—such as the buried resistor design challenges, repair issues, testing difficulties, and cost implications—you can make informed decisions that balance performance with practicality.

Whether you’re working on a cutting-edge electronics project or a cost-sensitive design, careful planning and collaboration are key to avoiding the traps of buried resistors. Evaluate your project’s specific needs, weigh the pros and cons, and consider hybrid solutions if the risks outweigh the rewards. With the right approach, you can harness the advantages of buried resistors while minimizing their downsides, ensuring a successful PCB implementation every time.

ALLPCB

ALLPCB