If you're looking for dependable ways to assemble printed circuit boards (PCBs) for water treatment control systems, you've come to the right place. At ALLPCB, we understand the unique challenges of designing and assembling PCBs for environments that demand precision, durability, and resistance to harsh conditions. In this blog, we'll dive into the most reliable PCB assembly methods tailored for water treatment applications, focusing on techniques like SMT assembly, wave soldering, through-hole assembly, mixed technology, and automated optical inspection. Whether you're working on control systems for filtration, purification, or chemical dosing, these methods ensure your PCBs perform flawlessly.

Why Water Treatment PCBs Require Specialized Assembly

Water treatment control systems operate in environments with high humidity, temperature fluctuations, and potential exposure to corrosive substances. The PCBs used in these systems must withstand these conditions while maintaining reliable performance. From controlling pumps and valves to monitoring water quality sensors, the electronics need to be robust and error-free. This is why choosing the right assembly method is critical. A poorly assembled PCB can lead to failures, downtime, and costly repairs in water treatment facilities.

Surface Mount Technology (SMT) for Water Treatment PCB Assembly

Surface Mount Technology, or SMT, is a popular method for assembling PCBs used in water treatment control systems. This technique involves placing components directly onto the surface of the PCB, allowing for a high density of components in a compact space. For water treatment applications, SMT offers several advantages, especially when space is limited in control units.

With SMT, components like microcontrollers, resistors, and capacitors can be mounted on both sides of the board, maximizing functionality. Modern SMT machines can place over 100,000 components per hour, ensuring fast and efficient production. Additionally, SMT reduces the risk of mechanical stress on components, which is vital for systems exposed to vibrations in industrial water treatment setups.

However, SMT-assembled PCBs for water treatment must be designed with protective coatings to shield against moisture and corrosion. Conformal coatings, often applied after assembly, add an extra layer of defense. For example, a typical coating might withstand humidity levels of up to 95% without compromising the board's performance.

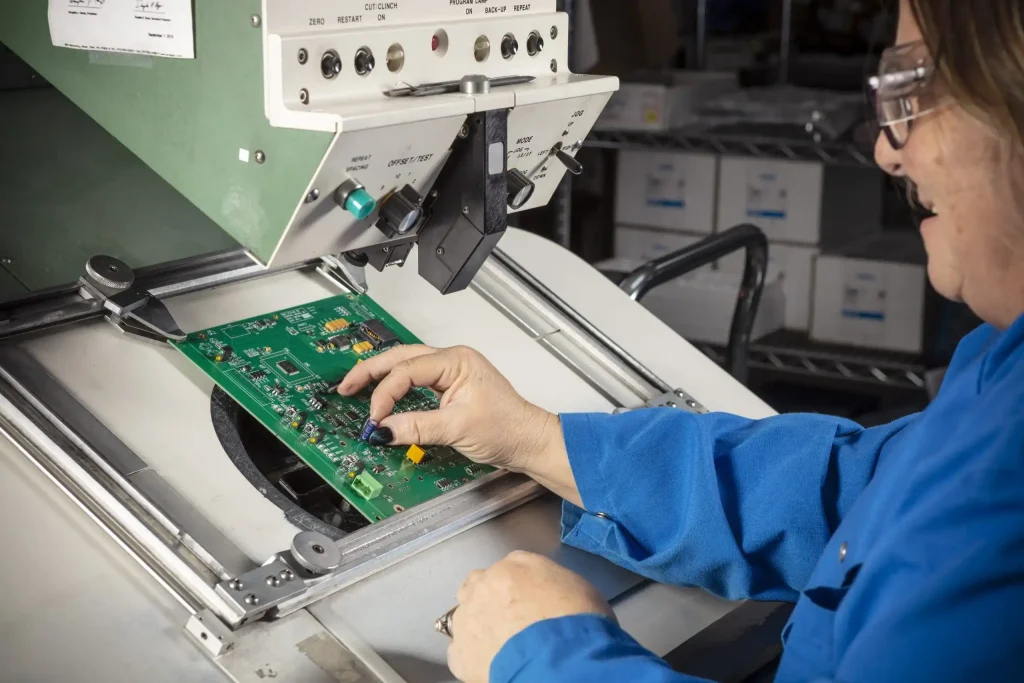

Image Suggestion: Include an image of an SMT assembly line with robotic arms placing components on a PCB. ALT Text: "SMT assembly line for water treatment PCB production"

Wave Soldering for Durable Water Treatment PCB Connections

Wave soldering is a bulk soldering process ideal for assembling PCBs with through-hole components, though it can also be used for some surface mount parts. In water treatment control systems, wave soldering is often used for larger components like connectors and power devices that require strong mechanical bonds to handle high currents or physical stress.

During wave soldering, the PCB passes over a pan of molten solder, creating a "wave" that solders components to the board. This method ensures robust connections that can endure the harsh conditions of water treatment environments. For instance, power components soldered via this method can handle currents up to 10 amps or more, depending on the design, making them suitable for driving pumps or motors in treatment plants.

While wave soldering is highly efficient for high-volume production, it requires careful design to prevent issues like solder bridging, especially in densely populated boards. Protective measures, such as proper spacing and thermal management, are essential to avoid overheating sensitive components during the process.

Through-Hole Assembly for Robust Water Treatment PCB Designs

Through-hole assembly remains a reliable choice for water treatment PCBs, particularly for components that need extra mechanical strength. In this method, component leads are inserted into drilled holes on the PCB and soldered on the opposite side. This creates a strong physical connection, ideal for parts like relays or heavy-duty connectors used in water treatment control systems.

Through-hole technology excels in applications where components are subjected to frequent vibrations or mechanical stress. For example, a through-hole soldered relay can withstand forces of up to 10G, ensuring it stays secure even in rugged industrial settings. Additionally, through-hole components are easier to replace or repair, which is a significant advantage in water treatment facilities where downtime must be minimized.

While through-hole assembly is less compact than SMT, it remains essential for specific high-power or high-reliability components in water treatment systems. Often, it is combined with other methods to achieve the best results.

Mixed Technology Assembly for Versatile Water Treatment PCBs

In many water treatment control systems, a combination of SMT and through-hole components is necessary to balance compactness with durability. This is where mixed technology assembly comes into play. By integrating both methods, mixed technology allows for the use of tiny, high-density components alongside larger, mechanically robust parts on the same PCB.

For instance, a water treatment PCB might use SMT for microprocessors and sensors to save space, while employing through-hole assembly for power transistors or terminal blocks that connect to external equipment. This hybrid approach optimizes the board for both performance and reliability. Mixed technology assembly often involves multiple soldering processes, such as reflow soldering for SMT components followed by wave soldering for through-hole parts.

The challenge with mixed technology lies in managing thermal profiles during soldering to prevent damage to sensitive components. Advanced assembly lines use precise temperature controls to ensure each part is soldered at the optimal heat level, often within a range of 220°C to 260°C for reflow soldering.

Automated Optical Inspection (AOI) for Flawless Water Treatment PCB Assembly

Quality control is non-negotiable in water treatment applications, where a single PCB failure can disrupt an entire system. Automated Optical Inspection (AOI) is a critical step in ensuring the reliability of assembled PCBs. AOI systems use high-resolution cameras and advanced algorithms to inspect boards for defects such as misaligned components, solder bridges, or missing parts.

In water treatment PCB assembly, AOI can detect issues with precision down to 0.01mm, ensuring that even the smallest errors are caught before the board is deployed. This technology is especially useful for high-density SMT boards, where manual inspection is impractical. By identifying defects early, AOI reduces the risk of costly rework and guarantees that the PCB meets the stringent standards required for water treatment control.

At ALLPCB, we integrate AOI into our assembly process to provide customers with the highest quality boards. This step is often followed by functional testing to verify that the PCB operates correctly under simulated conditions, such as high humidity or temperature swings.

Key Considerations for Water Treatment PCB Assembly

Beyond choosing the right assembly method, several factors must be considered to ensure the reliability of PCBs in water treatment applications. These include:

- Material Selection: Use FR-4 or other moisture-resistant PCB materials with high thermal stability. Look for materials with a glass transition temperature (Tg) of at least 150°C to handle industrial conditions.

- Protective Coatings: Apply conformal coatings or potting compounds to protect against moisture, dust, and chemicals. Silicone-based coatings, for example, can resist water ingress at depths up to 1 meter.

- Design for Environment: Incorporate wider trace spacing and robust grounding to prevent short circuits in humid environments. A typical trace width of 0.2mm or more can reduce the risk of corrosion-related failures.

- Thermal Management: Ensure adequate heat dissipation for power components, as overheating can accelerate wear in humid conditions. Heat sinks or thermal vias can keep temperatures below 85°C for critical parts.

By addressing these factors during the design and assembly phases, you can significantly extend the lifespan of your water treatment control PCBs.

Benefits of Partnering with ALLPCB for Water Treatment PCB Assembly

At ALLPCB, we specialize in delivering high-quality PCB assembly services tailored to the unique needs of water treatment applications. Our state-of-the-art facilities support SMT, through-hole, and mixed technology assembly, ensuring that your boards are built to last. We also employ rigorous quality control measures, including AOI and functional testing, to guarantee defect-free products.

Our team understands the importance of durability and precision in water treatment control systems. We work closely with clients to select the best materials, coatings, and assembly methods for their specific needs. Whether you require a compact SMT design or a robust through-hole board, we have the expertise to deliver on time and within budget.

Conclusion: Building Reliable Water Treatment Control Systems with the Right PCB Assembly

Assembling PCBs for water treatment control systems demands careful attention to detail and the use of reliable methods like SMT, wave soldering, through-hole, and mixed technology assembly. Each technique offers unique benefits, from compact designs to strong mechanical connections, ensuring that your PCBs can withstand the challenging conditions of water treatment environments. Automated optical inspection further enhances quality by catching defects early, providing peace of mind that your boards will perform as expected.

By understanding these assembly methods and incorporating protective measures like conformal coatings and robust designs, you can create water treatment control systems that are both efficient and long-lasting. At ALLPCB, we're committed to supporting your projects with top-tier assembly services, helping you achieve success in every application.

ALLPCB

ALLPCB