In the fast-paced world of retail and hospitality, Point-of-Sale (POS) systems are the backbone of smooth transactions and efficient operations. At the heart of these systems lies a critical component: the printed circuit board (PCB). If you're searching for insights into the POS PCB manufacturing process, PCB assembly for POS, or ways to achieve cost-effective POS PCB manufacturing, you've come to the right place. This guide will walk you through every step—from design to deployment—while focusing on component sourcing for POS PCBs and high-reliability PCB manufacturing to ensure your systems perform flawlessly.

Whether you're an engineer, a product manager, or a business owner, understanding how to create durable and efficient POS PCBs can save time, reduce costs, and improve customer experiences. Let’s dive into the detailed process of bringing a POS PCB from concept to reality with actionable insights and practical tips.

Why POS PCBs Are Critical for Modern Business Systems

POS systems handle everything from payment processing to inventory tracking, often in high-traffic, demanding environments. The PCB inside these systems must withstand constant use, resist environmental stressors like heat and humidity, and ensure secure data transmission. A poorly designed or manufactured PCB can lead to system failures, costly downtime, and frustrated customers.

High-reliability PCB manufacturing is not just a luxury—it’s a necessity for POS systems. With the right approach to design, sourcing, and assembly, you can build PCBs that meet the rigorous demands of modern retail while keeping costs under control. Let’s explore how to achieve this through a structured manufacturing process.

Step 1: Designing a POS PCB for Optimal Performance

The journey of POS PCB manufacturing begins with design. A well-thought-out design lays the foundation for functionality, reliability, and cost-efficiency. Here are the key considerations during this phase:

- Defining Requirements: Start by identifying the specific needs of your POS system. Will it support multiple payment methods like contactless cards or mobile wallets? Does it need to integrate biometric authentication for security? These requirements will dictate the complexity of your PCB layout and the components you’ll need.

- Signal Integrity: POS systems often process high-speed transactions, requiring PCBs with excellent signal integrity. Aim for controlled impedance values, typically around 50 ohms for high-speed signals, to prevent data loss or interference.

- Thermal Management: Continuous operation generates heat. Incorporate thermal vias and heat sinks in your design to dissipate heat effectively, ensuring components operate within safe temperature ranges (often below 85°C for most ICs).

- Compact Layout: Space is limited in POS devices. Use multilayer PCBs (4-8 layers are common for POS systems) to fit complex circuitry into a small footprint while maintaining clear separation between power and signal layers to reduce noise.

A robust design phase minimizes costly revisions later. Use simulation tools to test for signal delays, power distribution, and thermal performance before moving to prototyping.

Step 2: Component Sourcing for POS PCBs

Effective component sourcing for POS PCBs is crucial for balancing quality, reliability, and cost. The components you choose directly impact the performance and longevity of your POS system. Here’s how to approach sourcing:

- Quality Over Cost: Opt for components from trusted suppliers with proven reliability. For example, microcontrollers and payment processing chips must meet industry standards for security and speed, such as PCI compliance for handling card data.

- Availability and Lead Times: Supply chain disruptions can delay production. Source components with consistent availability and reasonable lead times (aim for suppliers with stock levels updated in real-time).

- Power Efficiency: POS systems often run on limited power, especially portable units. Choose low-power components, such as processors with operating voltages around 1.8V to 3.3V, to extend battery life and reduce heat output.

- Environmental Durability: Select components rated for wide temperature ranges (e.g., -20°C to 70°C) and high humidity to ensure reliability in diverse retail environments like outdoor kiosks or busy kitchens.

Building strong relationships with component distributors can also help secure better pricing and priority during shortages, a key factor in cost-effective POS PCB manufacturing.

Step 3: The POS PCB Manufacturing Process

The POS PCB manufacturing process transforms your design into a physical board ready for assembly. This multi-stage process requires precision to ensure the final product meets quality standards. Here’s a breakdown of the key steps:

- File Preparation: Convert your design files into manufacturing formats like Gerber files. Include detailed specifications for layer stack-up, material type (often FR-4 for cost and durability), and board thickness (typically 1.6mm for standard POS PCBs).

- Material Selection: Choose materials that balance cost and performance. FR-4 is widely used for its mechanical strength and thermal resistance, with a dielectric constant of around 4.5, suitable for most POS applications.

- Fabrication: This includes etching copper layers to form traces, drilling vias for interlayer connections, and applying a solder mask for protection. Precision in trace width (often 6-8 mils for signal lines) and spacing is critical to avoid short circuits.

- Surface Finish: Apply a surface finish like HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold) to protect copper traces and ensure good solderability. ENIG is preferred for POS PCBs due to its durability and flat surface for fine-pitch components.

- Testing: Perform electrical tests like flying probe or in-circuit testing to detect open circuits or shorts before assembly. Aim for a defect rate below 1% to ensure reliability.

Partnering with a manufacturer that prioritizes quality control at every stage is essential for high-reliability PCB manufacturing. This minimizes the risk of failures in the field, where repairs can be costly and disruptive.

Step 4: PCB Assembly for POS Systems

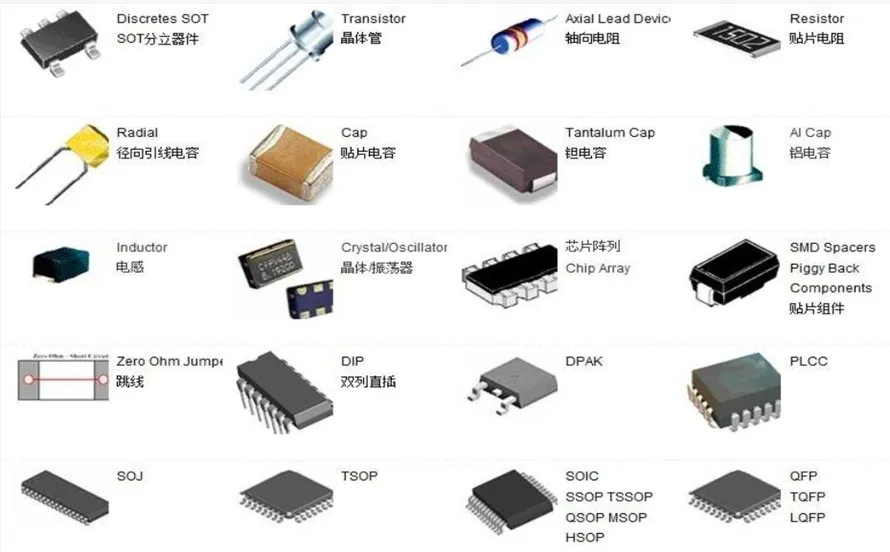

Once the bare PCB is ready, the next step is PCB assembly for POS. This process involves placing and soldering components onto the board to create a functional unit. Here’s what you need to know:

- Surface Mount Technology (SMT): Most POS PCBs use SMT for assembly due to its precision and ability to handle small components. Automated pick-and-place machines can position components with accuracies of ±0.01mm, ensuring consistent results.

- Reflow Soldering: After component placement, boards pass through a reflow oven to melt solder paste and form secure connections. Maintain peak temperatures around 245°C for lead-free solder to avoid damaging sensitive components.

- Through-Hole Assembly: For larger connectors or components requiring extra strength, through-hole technology may be used. This often involves manual or wave soldering for robust joints.

- Inspection: Use Automated Optical Inspection (AOI) to check for misaligned components or poor solder joints. X-ray inspection can also detect hidden defects in ball grid array (BGA) packages, common in POS processors.

A well-executed assembly process ensures that your POS PCB can handle the demands of real-world use without frequent failures. Focus on manufacturers with strict quality assurance protocols for the best results.

Step 5: Testing and Quality Assurance for High-Reliability

High-reliability PCB manufacturing hinges on rigorous testing and quality assurance. POS systems operate in environments where downtime isn’t an option, so thorough validation is non-negotiable. Key testing methods include:

- Functional Testing: Simulate real-world transactions to ensure the PCB processes payments, communicates with peripherals, and handles data securely. Test for transaction speeds—aim for under 2 seconds per transaction for optimal user experience.

- Environmental Testing: Expose the PCB to temperature cycles (e.g., -10°C to 60°C) and humidity levels (up to 85% RH) to verify performance under harsh conditions.

- Stress Testing: Run the system at maximum load for extended periods to identify weak points. For example, test continuous operation for 48 hours to simulate peak retail days.

- Compliance Testing: Ensure the PCB meets industry standards like EMI (electromagnetic interference) limits and safety regulations to avoid legal or operational issues.

Investing in comprehensive testing upfront reduces the likelihood of field failures, protecting your reputation and minimizing repair costs.

Step 6: Deployment and Integration into POS Systems

After manufacturing and testing, the final step is deploying the PCB into the POS system. Proper integration ensures seamless operation in the field. Consider these factors:

- Enclosure Design: The PCB must fit securely within the POS hardware enclosure, with proper alignment for ports, buttons, and displays. Allow for adequate airflow to prevent overheating.

- Firmware Integration: Load and test the firmware to ensure it communicates effectively with the PCB hardware. Optimize for low latency—response times under 100ms are ideal for user interactions.

- Field Testing: Deploy a small batch of units in real-world settings to identify any unforeseen issues before full-scale rollout. Monitor for errors or performance bottlenecks over a 30-day period.

Successful deployment marks the end of the manufacturing journey, but ongoing support and updates are vital to maintain performance as technology and user needs evolve.

Achieving Cost-Effective POS PCB Manufacturing

Balancing quality with affordability is a priority for many businesses. Here are proven strategies for cost-effective POS PCB manufacturing without compromising reliability:

- Design for Manufacturability (DFM): Simplify your PCB layout to reduce manufacturing complexity. For instance, minimize the number of layers (stick to 4-6 if possible) and avoid tight tolerances unless necessary.

- Bulk Ordering: Order components and PCBs in larger quantities to benefit from volume discounts. This can reduce per-unit costs by 10-20% depending on the supplier.

- Local Sourcing: Source components and manufacturing services closer to your location to cut shipping costs and lead times, especially for small to medium runs.

- Prototype Iterations: Invest in thorough prototyping to catch design flaws early. Fixing issues during production can cost 10 times more than addressing them in the design phase.

By focusing on efficiency at every stage, you can achieve significant savings while still delivering a high-quality product.

Conclusion: Building the Future of POS Systems with Reliable PCBs

From design to deployment, the journey of POS PCB manufacturing is a complex but rewarding process. By focusing on detailed design, strategic component sourcing for POS PCBs, precise POS PCB manufacturing processes, and thorough testing, you can create systems that power seamless transactions and enhance customer satisfaction. Emphasizing high-reliability PCB manufacturing ensures your POS devices stand up to the demands of modern business, while smart planning leads to cost-effective POS PCB manufacturing.

At ALLPCB, we’re committed to supporting you at every step, offering expertise and solutions tailored to your unique needs. Whether you’re building a single prototype or scaling up for mass production, a well-executed PCB assembly for POS can make all the difference. Let’s build the future of retail technology together with PCBs that deliver performance and reliability in every transaction.