Are you looking to elevate your PCB design with a unique and visually appealing touch? Using strategic silk screen color in PCB design can transform a standard board into a standout product, enhancing both visual appeal and branding. In this comprehensive guide, we'll explore how creative silkscreen color choices can make your PCBs distinctive, improve functionality, and reinforce your brand identity. From understanding the basics of PCB design silkscreen to implementing innovative color strategies, we've got you covered with actionable insights and tips.

What Is PCB Design Silkscreen and Why Does It Matter?

PCB design silkscreen refers to the layer of ink applied on a printed circuit board (PCB) to display text, symbols, and markings. This layer, often called the "legend," provides critical information like component labels, pin numbers, and assembly instructions. While its primary role is functional, the silkscreen also offers an opportunity to enhance the board's aesthetics and branding through color and design.

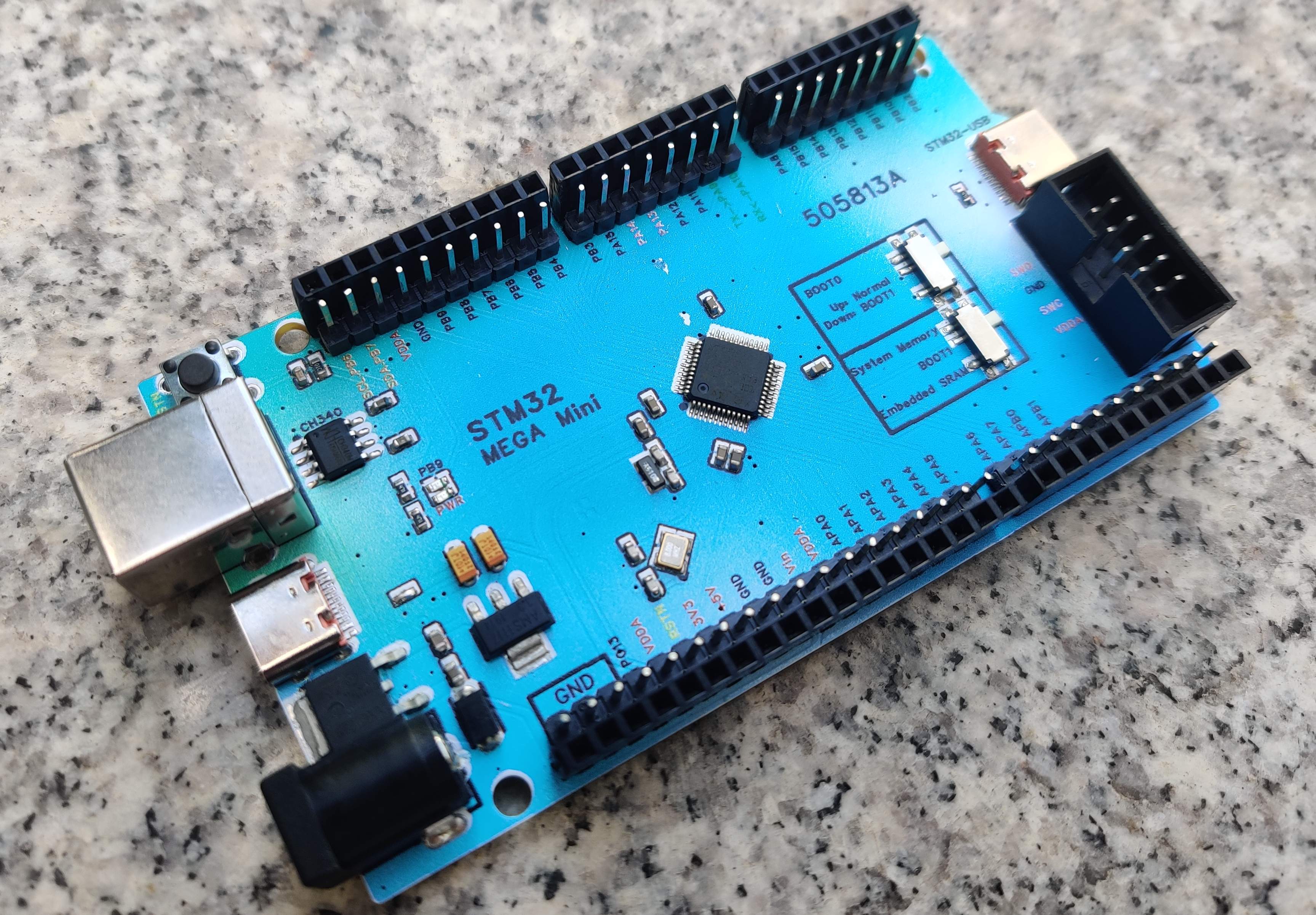

Traditionally, silkscreen is printed in white on green boards, but modern manufacturing allows for a variety of colors and creative approaches. Choosing the right silkscreen color for visual appeal can make your PCB easier to read, more professional-looking, and aligned with your brand's identity. For engineers and designers, leveraging unique silkscreen for PCBs can set your work apart in a competitive market.

The Functional Role of Silkscreen in PCB Design

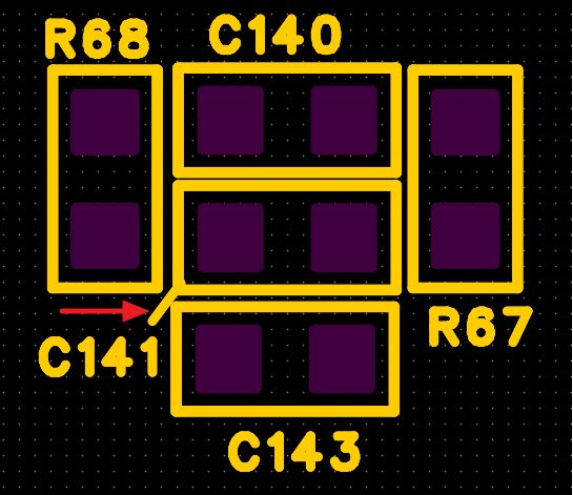

Before diving into creative silkscreen color strategies, it's important to understand the core purpose of silkscreen in PCB design. The silkscreen layer serves as a guide during assembly, testing, and troubleshooting. For instance, it helps technicians identify where to place components like resistors or capacitors, often labeled with values such as "R1" for a resistor or "C2" for a capacitor. Clear markings can reduce assembly errors by up to 30%, according to industry studies on manufacturing efficiency.

Moreover, silkscreen markings aid in debugging by indicating test points or polarity for diodes and capacitors. Without a well-designed silkscreen, even a small mistake in placement could lead to costly rework. Therefore, while aesthetics are important, functionality should always be the foundation of any PCB design silkscreen strategy.

Exploring Creative Silkscreen Color Options for PCBs

While functionality is key, the color of your silkscreen can significantly impact the overall look and feel of your PCB. Moving beyond the standard white-on-green, creative silkscreen color choices can make your board visually striking and memorable. Here are some ideas to consider when selecting silkscreen colors:

- Contrast for Readability: Choose colors that contrast well with the PCB substrate. For example, yellow or black silkscreen on a dark blue board ensures markings are easy to read under various lighting conditions.

- Multi-Color Silkscreen: Modern manufacturing techniques allow for multiple colors on a single board. Use different colors to categorize components—red for power lines, blue for signals, and green for ground connections—to improve clarity during assembly.

- Metallic Finishes: Some advanced processes offer metallic silkscreen inks, such as silver or gold, adding a premium look to your PCB while maintaining functionality.

By experimenting with these options, you can create unique silkscreen for PCBs that not only serves a practical purpose but also enhances the board's visual impact.

Silkscreen Color for Visual Appeal: Making Your PCB Stand Out

In a market flooded with standard-looking PCBs, using silkscreen color for visual appeal can give your product a competitive edge. A visually appealing PCB can leave a lasting impression on clients, hobbyists, or end-users, especially in consumer electronics where aesthetics matter. For instance, a bright orange silkscreen on a black board can evoke a sense of energy and innovation, while a sleek silver on white might convey sophistication and precision.

Consider the psychological impact of colors when designing your PCB. Studies in color theory suggest that blue inspires trust and reliability, making it a great choice for professional-grade electronics. On the other hand, vibrant colors like red or yellow can grab attention, ideal for hobbyist kits or educational tools. By aligning your silkscreen color with the intended perception of your product, you can create a cohesive and impactful design.

Silkscreen Color for Branding: Reinforcing Identity Through Design

One of the most powerful uses of silkscreen color is in branding. Silkscreen color for branding allows you to integrate your company's identity directly onto the PCB. Imagine a tech startup using its signature teal color in the silkscreen to match its logo and packaging. Every time a technician or customer sees the board, they’re reminded of the brand behind it.

To effectively use silkscreen for branding, follow these tips:

- Match Corporate Colors: Use your brand's primary or secondary colors for the silkscreen to create consistency across all products.

- Add Logos or Symbols: Incorporate a small logo or icon in the silkscreen layer to reinforce brand recognition. Ensure the design is simple to maintain clarity at small scales.

- Consistency Across Products: If you produce multiple PCB designs, maintain a uniform silkscreen color scheme to build a recognizable style.

Branding through silkscreen isn't just for large companies. Even small businesses or individual designers can use this technique to create a professional and memorable product identity.

Best Practices for Implementing Silkscreen Color in PCB Design

While creative silkscreen color choices can enhance your PCB, improper implementation can lead to issues like unreadable text or increased manufacturing costs. Here are some best practices to ensure your silkscreen design is both functional and visually appealing:

- Prioritize Legibility: Ensure text and symbols are large enough to read, typically at least 0.8mm in height for standard fonts. Avoid overly intricate designs that might blur during printing.

- Check Color Availability: Not all colors are available in every manufacturing process. Standard options like white, black, and yellow are widely supported, but custom colors may require additional setup costs or lead times.

- Consider Cost vs. Impact: Multi-color silkscreen or metallic finishes can increase production costs by 10-20% depending on the complexity. Weigh the benefits of visual appeal against your budget constraints.

- Test Under Different Lighting: Some colors may appear different under fluorescent or natural light. Test your design to ensure markings remain visible in typical working conditions.

Following these guidelines can help you achieve a balance between creativity and practicality in your PCB design silkscreen.

Technical Considerations for Silkscreen Color Application

From a technical standpoint, applying silkscreen color involves several considerations to ensure quality and durability. The silkscreen ink must withstand soldering temperatures, typically around 260°C for lead-free processes, without fading or peeling. Most manufacturers use epoxy-based inks for their heat resistance and adhesion properties, ensuring the markings last through the product's lifecycle.

Additionally, the thickness of the silkscreen layer, often between 0.1mm and 0.2mm, affects how well the color stands out. A thicker layer might improve visibility but could interfere with component placement if not carefully managed. Work closely with your manufacturing partner to select inks and processes that align with your design goals while maintaining reliability.

Case Studies: Successful Use of Silkscreen Color in PCB Design

To illustrate the impact of strategic silkscreen color, let's look at a few hypothetical examples of successful implementations:

- Consumer Electronics Startup: A small company designing wearable tech used a vibrant purple silkscreen on a black PCB to match its youthful, trendy branding. This choice not only made the product visually appealing but also helped it stand out at tech expos, attracting potential investors.

- Educational Tool Manufacturer: A company producing learning kits for students used multi-color silkscreen—red for power, blue for inputs, and green for outputs—to simplify assembly for beginners. Feedback showed a 25% reduction in assembly errors among users.

- Industrial Equipment Designer: For a rugged industrial controller, the designer opted for a high-contrast yellow silkscreen on a dark green board. This ensured markings were visible even in harsh, low-light environments, improving on-site maintenance efficiency.

These examples highlight how unique silkscreen for PCBs can address specific needs, from branding to usability, across different industries.

Future Trends in Silkscreen Color for PCB Design

As PCB manufacturing technology evolves, so do the possibilities for silkscreen design. One emerging trend is the use of UV-reactive or glow-in-the-dark inks, which can make markings visible in complete darkness—ideal for applications like emergency equipment. Another development is the integration of digital printing techniques, allowing for more intricate and detailed silkscreen designs without significant cost increases.

Additionally, sustainability is becoming a focus, with manufacturers exploring eco-friendly inks that reduce environmental impact without compromising durability. Staying ahead of these trends can position your PCB designs as cutting-edge and environmentally conscious, appealing to a broader audience.

Conclusion: Elevate Your PCB with Strategic Silkscreen Color

Enhancing your PCB design with strategic silkscreen color is more than just an aesthetic choice—it's a powerful tool for functionality, visual appeal, and branding. Whether you're aiming to improve readability with high-contrast colors, create a memorable look with creative silkscreen color, or reinforce your identity through silkscreen color for branding, the possibilities are endless. By following best practices and leveraging modern manufacturing capabilities, you can craft unique silkscreen for PCBs that stand out in any market.

Start experimenting with silkscreen colors in your next PCB design project. With thoughtful planning and execution, you can turn a simple circuit board into a work of art that communicates quality and innovation. Let your creativity shine through every layer of your design!

ALLPCB

ALLPCB