If you're an electrical engineer looking for ENIG alternatives for your PCB surface finishes, you're likely seeking options that balance cost, performance, and reliability. Electroless Nickel Immersion Gold (ENIG) is a popular choice due to its excellent solderability and corrosion resistance, but it can be expensive. So, what are the best alternatives? In this guide, we'll explore cost-effective and performance-driven options like HASL, OSP, Immersion Silver, and ENEPIG, comparing them directly to ENIG to help you make an informed decision. Whether you're prioritizing budget with HASL vs ENIG or performance with ENEPIG vs ENIG, we've got you covered with detailed insights and practical advice.

Why Look for ENIG Alternatives?

As an electrical engineer, you know that the surface finish of a printed circuit board (PCB) is critical. It protects the copper traces from oxidation, ensures good solderability, and impacts the overall reliability of the board. ENIG, with its nickel and gold layers, offers a flat surface, excellent corrosion resistance, and compatibility with fine-pitch components. However, its higher cost—often 20-30% more than other finishes—can be a dealbreaker for budget-conscious projects. Additionally, ENIG can suffer from issues like "black pad syndrome," a defect where nickel corrodes, leading to poor solder joints.

This is why exploring cost-effective PCB finishes is essential. Alternatives like HASL (Hot Air Solder Leveling), OSP (Organic Solderability Preservative), Immersion Silver, and ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) offer unique benefits and trade-offs. In the sections below, we'll dive deep into each option, comparing them to ENIG based on cost, performance, and application suitability.

Understanding ENIG: The Benchmark for PCB Finishes

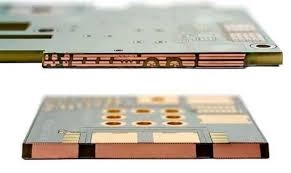

Before we explore alternatives, let's quickly recap what makes ENIG a go-to choice for many engineers. ENIG involves depositing a layer of nickel (typically 3-6 μm thick) over the copper, followed by a thin layer of gold (0.05-0.1 μm). This combination provides:

- Excellent corrosion resistance due to the gold layer.

- A flat surface ideal for fine-pitch components and surface-mount technology (SMT).

- Good shelf life, often exceeding 12 months without degradation.

However, ENIG's cost—driven by the gold layer and complex processing—can range from $0.10 to $0.20 per square inch, depending on the manufacturer and board complexity. Additionally, the risk of black pad syndrome can lead to reliability issues in high-stakes applications. These drawbacks push engineers to seek ENIG alternatives that deliver similar performance at a lower cost or with fewer risks.

HASL vs ENIG: The Cost-Effective Classic

Hot Air Solder Leveling (HASL) is one of the oldest and most widely used PCB finishes, often considered the default choice for cost-sensitive projects. In a direct HASL vs ENIG comparison, HASL stands out for its affordability, typically costing 30-50% less than ENIG (around $0.05 to $0.08 per square inch).

Key Features of HASL

- Process: Involves dipping the PCB in molten solder (tin-lead or lead-free) and using hot air to level the coating.

- Cost: Low, making it ideal for large-scale production.

- Solderability: Excellent, as the surface is already coated with solder.

- Durability: Decent resistance to handling and environmental stress.

Drawbacks of HASL Compared to ENIG

- Surface Flatness: Uneven coating (variations of 1-2 μm) makes it unsuitable for fine-pitch components (below 0.5 mm).

- Thermal Stress: The high-temperature process (around 260°C) can stress the board, risking warpage.

- Shelf Life: Shorter than ENIG, typically 6-12 months before oxidation affects solderability.

Best Use Cases

HASL is a great choice for through-hole components and prototypes where cost is a priority over precision. If your design doesn’t involve high-density SMT components, HASL can save you significant upfront costs compared to ENIG.

OSP vs ENIG: The Eco-Friendly Option

Organic Solderability Preservative (OSP) is another popular alternative, especially for engineers looking at OSP vs ENIG for environmentally friendly and low-cost options. OSP applies a thin organic coating (0.2-0.5 μm) over the copper to prevent oxidation.

Key Features of OSP

- Cost: Very low, often comparable to HASL at $0.05 to $0.07 per square inch.

- Flatness: Excellent, as there’s no added metal layer, making it suitable for fine-pitch components.

- Environmental Impact: Lead-free and free of heavy metals, aligning with RoHS standards.

Drawbacks of OSP Compared to ENIG

- Durability: Poor resistance to handling; the organic layer can degrade with repeated contact or exposure to humidity.

- Shelf Life: Short, typically 3-6 months, requiring quick assembly after application.

- Rework: Not ideal for multiple soldering cycles, as the coating breaks down under heat (above 200°C).

Best Use Cases

OSP is ideal for high-volume, quick-turnaround projects where boards will be assembled shortly after manufacturing. It’s a strong contender for consumer electronics with fine-pitch components, provided storage conditions are controlled.

Immersion Silver vs ENIG: The High-Performance Budget Option

For engineers comparing Immersion Silver vs ENIG, Immersion Silver offers a compelling mix of performance and cost. This finish deposits a thin layer of silver (0.1-0.3 μm) directly onto the copper through a chemical process.

Key Features of Immersion Silver

- Cost: Moderately priced, typically 10-20% cheaper than ENIG at $0.08 to $0.12 per square inch.

- Solderability: Excellent, with better wetting characteristics than ENIG, leading to stronger solder joints.

- Flatness: Very flat, suitable for fine-pitch and high-density designs.

- Signal Integrity: Low signal loss, making it ideal for high-frequency applications (e.g., RF circuits with impedance control around 50 ohms).

Drawbacks Compared to ENIG

- Tarnishing: Silver is prone to oxidation and tarnishing, especially in sulfur-rich environments, requiring anti-tarnish treatments or controlled storage.

- Shelf Life: Moderate, around 6-12 months, shorter than ENIG if not packaged properly.

Best Use Cases

Immersion Silver shines in high-frequency and high-speed digital applications where signal integrity is critical. It’s a solid choice for telecommunications and automotive electronics, provided tarnishing risks are mitigated.

ENEPIG vs ENIG: The Premium Alternative

When looking at ENEPIG vs ENIG, ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) emerges as a premium option for applications demanding the highest reliability. It adds a palladium layer (0.05-0.1 μm) between the nickel and gold, addressing some of ENIG’s weaknesses.

Key Features of ENEPIG

- Reliability: Eliminates black pad syndrome by preventing nickel corrosion with the palladium barrier.

- Versatility: Supports both soldering and wire bonding (e.g., gold or aluminum wire), unlike ENIG, which is primarily for soldering.

- Durability: Excellent corrosion resistance and shelf life (over 12 months).

Drawbacks Compared to ENIG

- Cost: Higher than ENIG, often 10-20% more expensive ($0.12 to $0.25 per square inch) due to the additional palladium layer.

- Complexity: More complex manufacturing process, potentially increasing lead times.

Best Use Cases

ENEPIG is the go-to finish for high-reliability applications like aerospace, medical devices, and advanced telecommunications where failure is not an option. It’s also ideal for mixed assembly processes requiring wire bonding.

Comparing Cost-Effective PCB Finishes: A Quick Reference Table

To help you choose the right finish, here’s a comparison table summarizing key metrics for ENIG and its alternatives:

| Finish | Cost ($/sq inch) | Shelf Life (Months) | Flatness | Solderability | Best For |

|---|---|---|---|---|---|

| ENIG | 0.10-0.20 | 12+ | Excellent | Good | Fine-pitch, SMT |

| HASL | 0.05-0.08 | 6-12 | Poor | Excellent | Through-hole, Prototypes |

| OSP | 0.05-0.07 | 3-6 | Excellent | Good | Quick assembly, Consumer |

| Immersion Silver | 0.08-0.12 | 6-12 | Excellent | Excellent | High-frequency, RF |

| ENEPIG | 0.12-0.25 | 12+ | Excellent | Excellent | Aerospace, Medical |

How to Choose the Right ENIG Alternative for Your Project

Selecting the best PCB finish depends on several factors specific to your project. Here’s a step-by-step guide to help you decide:

- Budget Constraints: If cost is your primary concern, start with HASL or OSP. They’re the most cost-effective PCB finishes and can save you up to 50% compared to ENIG.

- Component Density: For high-density or fine-pitch designs (below 0.5 mm pitch), prioritize flat finishes like OSP, Immersion Silver, or ENEPIG over HASL.

- Environmental Conditions: If your PCB will face harsh environments (high humidity, sulfur exposure), avoid Immersion Silver due to tarnishing risks and opt for ENIG or ENEPIG.

- Signal Requirements: For high-frequency applications where signal integrity is key (e.g., maintaining 50-ohm impedance), Immersion Silver often outperforms ENIG due to lower signal loss.

- Reliability Needs: For mission-critical applications, invest in ENEPIG to avoid risks like black pad syndrome and ensure long-term durability.

Real-World Insights: What Engineers Are Saying

In my conversations with fellow engineers, I’ve noticed a few trends. For instance, a colleague working on automotive radar systems swears by Immersion Silver for its signal performance at frequencies above 5 GHz. However, he emphasized the need for vacuum-sealed packaging to prevent tarnishing during storage. On the other hand, a friend in consumer electronics often sticks with OSP for quick-turn projects, as the short shelf life isn’t an issue with their fast assembly cycles. These real-world experiences highlight how application-specific needs drive the choice of finish.

Final Thoughts on ENIG Alternatives

Finding the right alternative to ENIG doesn’t have to be a daunting task. Whether you’re weighing HASL vs ENIG for a budget prototype, OSP vs ENIG for a quick consumer product, Immersion Silver vs ENIG for high-frequency designs, or ENEPIG vs ENIG for maximum reliability, each option has its place. By understanding your project’s specific requirements—cost, component type, environmental exposure, and performance needs—you can select a cost-effective PCB finish that doesn’t compromise on quality.

Remember, there’s no one-size-fits-all solution. Test different finishes in small runs if possible, and consult with your PCB manufacturer for insights on process compatibility.

ALLPCB

ALLPCB