If you're looking for ways to safeguard your surface mount technology (SMT) PCBs from environmental hazards, conformal coating is a proven solution. This protective layer shields your boards from moisture, dust, chemicals, and thermal stress, ensuring longevity and reliability. In this comprehensive guide, we'll dive deep into the world of conformal coating for SMT PCBs, exploring its importance, materials, application methods, and inspection techniques to help you protect your valuable investment.

Why Conformal Coating Matters for SMT PCB Protection

SMT PCBs are at the heart of modern electronics, packed with tiny, densely placed components that are highly sensitive to environmental factors. Without proper protection, these boards can fail due to corrosion, short circuits, or mechanical stress. Conformal coating acts as a barrier, preserving the performance of your electronics by preventing contaminants like salts or moisture from reaching critical circuit nodes.

Studies show that unprotected PCBs exposed to high humidity (above 85% relative humidity) can experience corrosion-related failures within months. In contrast, a well-applied conformal coating can extend a board's lifespan by years, even in harsh conditions like industrial or automotive environments. For anyone investing in SMT PCB design and manufacturing, this protection is non-negotiable.

What Is Conformal Coating and How Does It Work?

Conformal coating is a thin polymeric film applied to PCBs to protect them from adverse conditions such as moisture, thermal shock, vibration, and contamination. The term "conformal" refers to how the coating molds to the irregular surface of the board, ensuring complete coverage over components and solder joints.

The primary function of the coating is to increase dielectric resistance, which prevents electrical shorts, and to maintain operational integrity under stress. For SMT PCBs, where components are smaller and closer together (often with spacing as tight as 0.5 mm), this protection is critical to avoid issues like tin whisker growth or unintended conductive paths caused by contaminants.

Key Benefits of Conformal Coating for SMT PCBs

- Environmental Protection: Shields against humidity, salt spray, and corrosive chemicals.

- Thermal Stability: Protects against temperature extremes, often ranging from -40°C to 150°C, depending on the coating material.

- Vibration Resistance: Reduces mechanical stress on delicate SMT components during operation or transport.

- Enhanced Reliability: Minimizes the risk of failure in critical applications like medical devices or aerospace systems.

Types of Conformal Coating Materials for SMT PCBs

Choosing the right conformal coating materials is essential for effective SMT PCB protection. Each material has unique properties suited to specific environments and applications. Below are the most common types used in the industry:

1. Acrylic Resin (AR)

Acrylic coatings are popular due to their ease of application and removal for rework. They offer good moisture resistance and dielectric strength (typically around 80-100 kV/mm). However, they may not withstand extreme temperatures or harsh chemicals, making them ideal for consumer electronics in mild environments.

2. Silicone Resin (SR)

Silicone coatings excel in high-temperature environments, withstanding ranges from -55°C to 200°C. They are flexible, which helps with vibration resistance, but can be harder to remove for repairs. These are often used in automotive and industrial applications.

3. Polyurethane Resin (UR)

Polyurethane provides excellent chemical resistance and durability, protecting against solvents and abrasion. With a dielectric strength of about 50-80 kV/mm, it’s suitable for harsh industrial settings but can be challenging to rework due to its toughness.

4. Epoxy Resin (ER)

Epoxy coatings are extremely durable and offer superior mechanical strength. They are ideal for extreme conditions but are difficult to remove, often requiring specialized tools or chemicals. Their dielectric strength can reach up to 110 kV/mm, making them a top choice for military applications.

5. Parylene

Parylene is a unique vapor-deposited coating that provides uniform coverage, even in tight spaces on SMT PCBs. It offers excellent barrier properties against moisture and chemicals but requires specialized equipment for application and removal. It’s often used in medical and aerospace industries due to its reliability.

Conformal Coating Application Methods for SMT PCBs

The effectiveness of conformal coating application depends on the method used. Each technique has its advantages, depending on production volume, board complexity, and budget. Here are the primary methods for applying conformal coating to SMT PCBs:

1. Brush Coating

Brush coating involves manually applying the coating using a brush. It’s cost-effective for low-volume production or prototypes but lacks precision, often leading to uneven coverage. This method is best for quick repairs or small-scale projects.

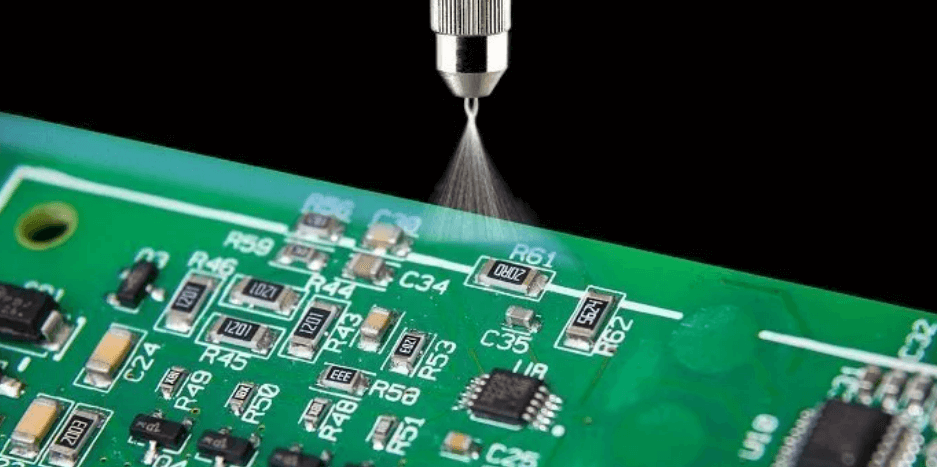

2. Spray Coating

Spray coating, whether manual or automated, uses an aerosol or spray gun to apply the coating. It offers better coverage than brushing and is suitable for medium-volume production. However, overspray can waste material, and masking is often required to protect specific areas.

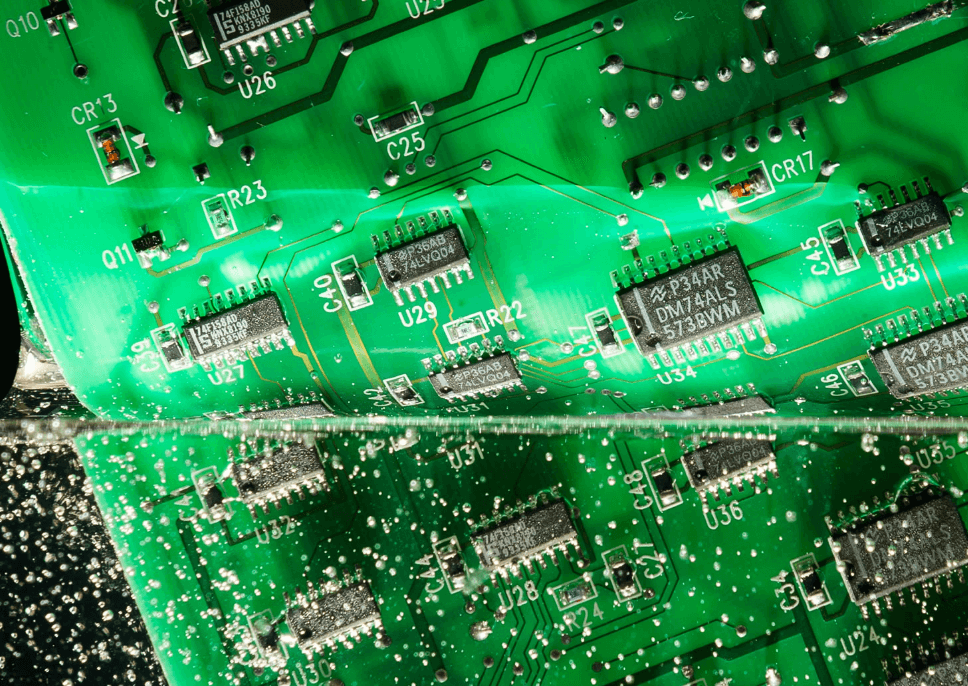

3. Dip Coating

Dip coating involves immersing the PCB into a liquid coating material. It ensures complete coverage, even in hard-to-reach areas, but requires careful control to avoid pooling or air bubbles. This method works well for high-volume production but may not be ideal for complex SMT designs with sensitive components.

4. Selective Coating

Selective coating uses robotic systems to apply coating only to designated areas of the PCB, avoiding connectors or other no-coat zones. This method is highly precise, reducing material waste, and is ideal for complex SMT PCBs in high-volume manufacturing. Automated systems can achieve coating thicknesses as precise as 25-100 microns.

5. Vapor Deposition (for Parylene)

Vapor deposition is a specialized process for Parylene coatings, where the material is applied as a gas and condenses into a uniform film. It provides unmatched coverage for intricate SMT designs but requires expensive equipment, making it suitable for high-end applications.

Before application, surface preparation is critical. Boards must be cleaned using processes like vapor degreasing to remove contaminants. Any residue can lead to pinholes or adhesion issues, compromising protection.

Conformal Coating Inspection: Ensuring Quality Protection

After applying the coating, conformal coating inspection is a crucial step to verify that the layer is uniform, free of defects, and fully protective. Poorly applied coatings can lead to failures, so thorough inspection ensures reliability. Here are the key inspection techniques:

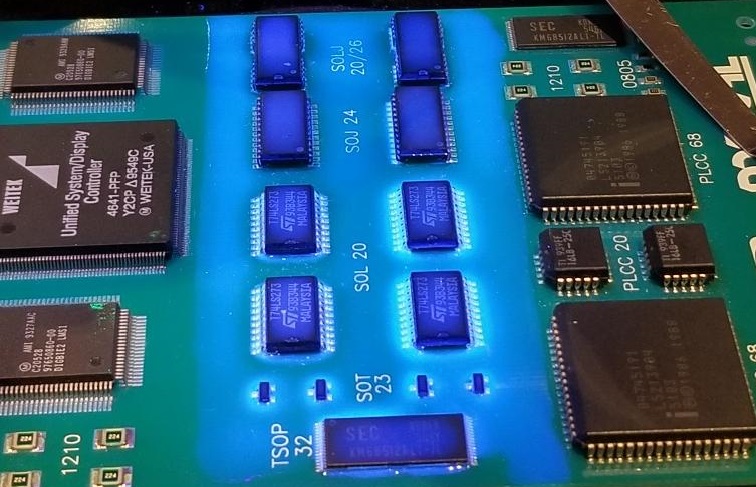

1. Visual Inspection Under UV Light

Most conformal coatings contain a fluorescent dye that glows under ultraviolet (UV) light. This makes it easy to spot areas with insufficient coverage or defects like bubbles or cracks. For SMT PCBs, where components are densely packed, UV inspection helps identify missed spots around small parts.

2. Thickness Measurement

Coating thickness is critical for performance. Too thin (below 25 microns), and it may not provide adequate protection; too thick (above 100 microns), and it can stress components or interfere with heat dissipation. Tools like micrometers or non-destructive eddy current testers are used to measure thickness accurately.

3. Adhesion Testing

Adhesion tests ensure the coating bonds well to the PCB surface. A common method is the cross-hatch test, where a grid is cut into the coating, and tape is applied to check if it peels off. Poor adhesion can lead to delamination under thermal or mechanical stress.

4. Environmental Stress Testing

To simulate real-world conditions, coated SMT PCBs are subjected to humidity, temperature cycling (e.g., -40°C to 85°C), and salt spray tests. These tests confirm that the coating can withstand the intended operating environment without cracking or degrading.

Challenges in Conformal Coating for SMT PCBs

While conformal coating offers immense benefits, there are challenges to consider:

- Component Density: SMT PCBs often have tightly spaced components, making uniform coating application difficult without masking or selective methods.

- Rework and Repair: Removing coating for repairs can be time-consuming, especially with tougher materials like epoxy or Parylene.

- Cost vs. Benefit: High-end coatings like Parylene or automated selective coating systems can be expensive, requiring a balance between cost and the level of protection needed.

- White Residue or Blooming: Some coatings, especially polyurethane, can develop a white residue over time due to moisture interaction, affecting aesthetics and potentially performance.

Addressing these challenges requires careful planning, from selecting the right material to choosing an application method that suits your production scale and board design.

Best Practices for Applying Conformal Coating to SMT PCBs

To maximize the effectiveness of SMT PCB protection, follow these best practices:

- Clean Thoroughly: Ensure the PCB is free of flux residues, oils, or dust before coating to prevent adhesion issues.

- Mask Sensitive Areas: Protect connectors, test points, or other no-coat zones using tapes or temporary masks during application.

- Control Thickness: Aim for a consistent thickness within the recommended range (typically 25-75 microns for most materials) to balance protection and functionality.

- Test After Coating: Conduct thorough inspections and environmental tests to validate the coating’s performance before deployment.

- Choose the Right Material: Match the coating material to your operating environment—silicone for high temperatures, polyurethane for chemical exposure, etc.

Conclusion: Safeguard Your SMT PCBs with Conformal Coating

Conformal coating is a vital step in protecting your SMT PCBs from the myriad of environmental threats they face. By understanding the types of conformal coating materials, mastering conformal coating application techniques, and ensuring rigorous conformal coating inspection, you can significantly enhance the durability and reliability of your electronics. Whether you're designing for consumer gadgets, industrial machinery, or critical systems, investing in proper SMT PCB protection ensures that your products perform flawlessly over time.

At ALLPCB, we’re committed to helping you achieve the highest quality in PCB manufacturing and protection. With the right conformal coating strategy, you can confidently protect your investment and deliver exceptional results to your customers.

ALLPCB

ALLPCB