Overview

Shelf stability is a core factor for safety and efficiency in automated warehousing. Long-term uneven loading, such as consistently placing heavy items on one side, can produce slow, hidden deformation that is difficult to detect by visual inspection. Over time this deformation may accumulate and lead to structural instability. A wireless tilt sensor using high-precision real-time monitoring and data analysis can quantify these subtle trends and support timely intervention.

Hidden Risk: Slow Deformation from Long-Term Uneven Loading

In high-density storage environments, uneven load distribution often occurs. For example, heavy goods continuously stored on one side create eccentric loads that induce slow plastic deformation at column and beam joints. This deformation typically progresses at a rate on the order of millimeters per year, making it invisible to the naked eye. Conventional manual inspections, such as monthly plumb-bob checks, are usually insufficient to capture the dynamic trend. Industry guidance indicates that for racks taller than 20 m, lateral displacement at the top should be controlled within one per mille (0.001), equivalent to no more than 2 cm. Long-term eccentric loading can quietly increase displacement until safety thresholds are exceeded.

Key characteristics of this problem:

- Cumulative: deformation results from sustained loading over time; single inspections do not reveal the trend.

- Concealed: very small tilt angles (for example 0.005°–0.01°) do not immediately trigger alarms but can gradually weaken structural capacity.

- Prediction difficulty: traditional methods monitor instantaneous deformation and lack the historical basis needed to predict fatigue life.

Technical Approach: High-Precision Monitoring and Trend Prediction

Wireless tilt sensors address these challenges through the following technical features.

Micrometer-level measurement accuracy

Sensors based on MEMS technology measure tilt changes on both X and Y axes with accuracy of ±0.005° (about 0.1 mm per meter of height). In a power utility deployment, continuous monitoring of 17,000 storage locations kept vertical deviation within one per mille, removing reliance on delayed manual inspections.

Long-term data accumulation and trend analysis

Sensors upload data at configurable intervals, for example from 60 seconds to 36 hours, creating a historical database. Using models such as grey prediction and other time-series algorithms, the system analyzes deformation sequences to provide early warnings of emerging risks. In a sanitary ware warehouse case, analysis of foundation settlement and uneven loading informed rack reinforcement decisions.

Adaptive alerting

Systems support multi-level thresholds, for example triggering an immediate alarm when tilt exceeds 0.5°. They also implement trend-based alerts for slow deformation: if the weekly growth rate of tilt at a point exceeds 15%, the system flags that location for inspection even if absolute thresholds have not been reached.

Field Validation: From Hidden Deformation to Proactive Intervention

Manufacturing warehouse: early identification of eccentric loads

In an automated manufacturing warehouse, sensors detected an increased tilt rate in an area where motor components were stored on one side. By comparing historical data with 5–10 minute resolution, the monitoring system identified a month-over-month tilt rate increase of 20%, prompting load redistribution to avoid structural fatigue.

Food and beverage logistics: long-term load management

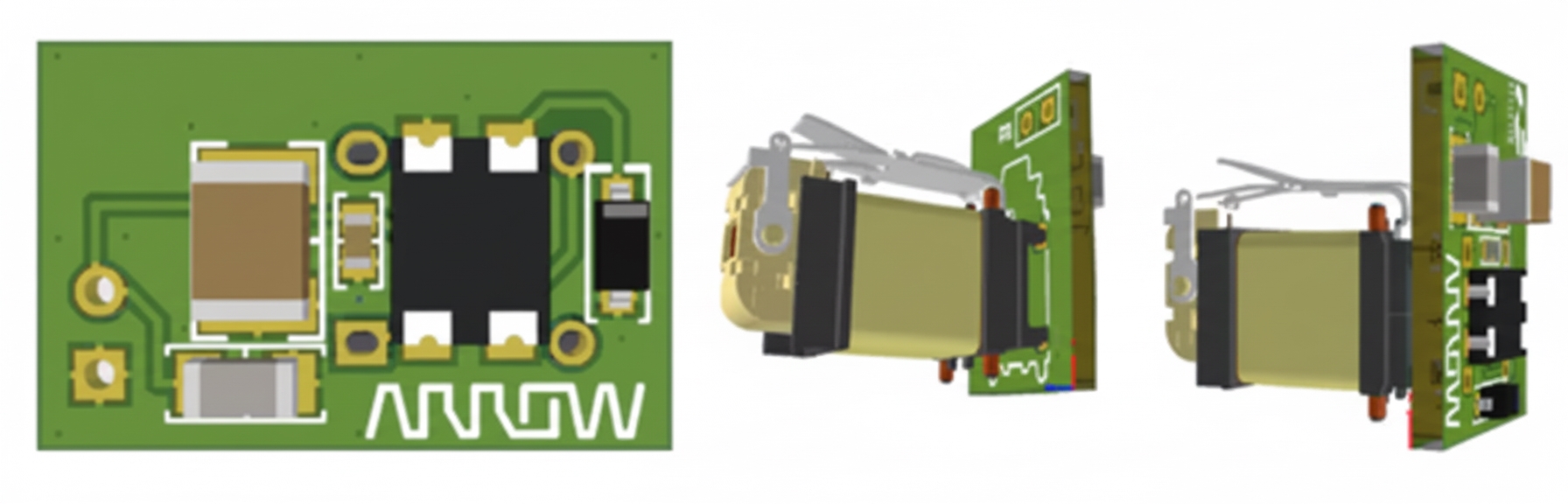

At a high-throughput beverage factory, racks see frequent load fluctuations. Deployment of ZCT330M series sensors provided real-time alarms and enabled analysis of deformation patterns under different loading regimes, supporting optimization of maintenance intervals.

Summary

High-precision wireless tilt sensors combined with long-term data tracking and adaptive alerting convert hidden deformation caused by uneven loading into quantifiable risk indicators. Continuous monitoring enables proactive interventions that reduce the likelihood of structural failure in warehouse shelving systems.

ALLPCB

ALLPCB