Overview of AI

Artificial intelligence (AI) is a branch of computer science focused on creating systems or machines that exhibit human-like intelligent behavior. Its goals include simulating a range of cognitive functions such as learning, reasoning, problem solving, perception, and language understanding. AI encompasses multiple technical areas, including machine learning, deep learning, natural language processing, computer vision, and robotics.

Core Concept: Latent Space

Machine learning and deep learning models often require significant hardware resources and perform complex neural network computations. A practical concept that helps explain how these computations relate to real-world applications is the latent space. In practice, latent space refers to a lower-dimensional representation that encodes key features of high-dimensional raw data. During the transformation into latent space, data dimensionality is reduced while preserving important characteristics of the original input. Each point in latent space corresponds to a particular feature or combination of features from the original data.

Latent space concepts apply across many domains, including numerical data, image data, and text, as well as combinations of these. Common uses include dimensionality reduction, data compression, representation learning, prediction, and data generation.

AI in Manufacturing and Semiconductor Production

AI applications have been increasingly adopted in manufacturing, and their use cases continue to expand. In semiconductor manufacturing, AI algorithms, machine learning/deep learning methods, and data analytics can be used to optimize and automate production-line processes. Typical practical applications include:

- Predictive maintenance: By analyzing sensor data from automated equipment and machinery, AI can predict when maintenance is needed. This enables scheduled interventions that reduce unexpected downtime and improve overall production uptime.

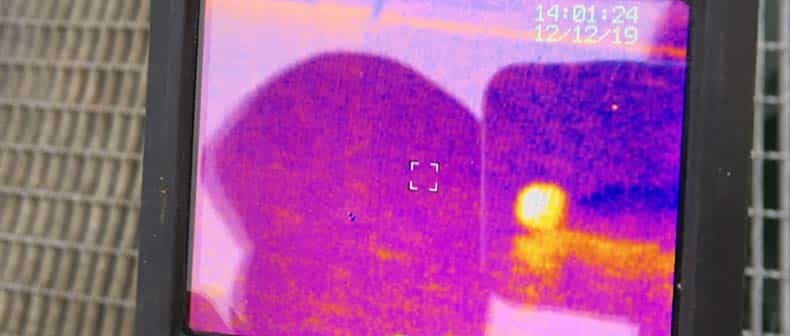

- Quality assurance (QA): AI can automatically analyze camera images and other sensor inputs for real-time quality control, detecting defects or anomalies in process outputs.

- Process parameter optimization: AI algorithms can analyze various data streams to optimize process settings and improve production efficiency.

- Robotic process automation (RPA): AI can be combined with RPA to automate repetitive, rule-based tasks.

- Supply chain optimization: AI can support procurement, demand forecasting, order tracking, logistics allocation, and financial management across the supply chain.

Benefits of Integrating AI and Automation

- Improved accuracy and precision: Data-driven methods allow AI systems to continuously learn and refine their outputs based on large datasets.

- Higher efficiency and productivity: AI-driven automation reduces manual operations and streamlines production workflows.

- Cost savings: Automating routine and repetitive tasks enables more efficient resource allocation.

The combination of AI and automation can create intelligent, efficient, and responsive manufacturing systems. AI's learning and predictive capabilities add value to automation by enabling better decision making and more optimized processes.

ALLPCB

ALLPCB