Overview

In industrial condition monitoring systems, fans are widely used rotating machines in power generation, metallurgy, chemical processing, and cement production. Their operational stability directly affects line efficiency and safety. Fans often run continuously under high load, so bearing wear, rotor imbalance, misalignment, and blade looseness can generate abnormal vibration. If these issues are not detected in time, they can cause unplanned shutdowns or severe equipment damage. Effective vibration monitoring has therefore become an essential part of predictive maintenance.

Sensors and Measurement Strategy

Vibration sensors act as a stethoscope for mechanical condition, collecting vibration signals from fans in real time to support fault diagnosis. In practical deployments, accelerometers are typically mounted on bearing housings or other key points on the casing. By monitoring vibration amplitude, spectral features, and trend changes, common fault patterns can be identified. For example, a pronounced 1×RPM peak often indicates rotor imbalance; dominant 2×RPM components may point to misalignment; and increased energy in high-frequency bands is commonly associated with early bearing damage.

Case Study: High-Temperature Fan in a Cement Plant

In one case, a large cement plant used a high-temperature fan rated at 2000 kW with operating temperatures above 200°C in a dusty and electromagnetically noisy environment. Traditional manual inspections could not provide the high-frequency, continuous coverage required. After introducing an online vibration monitoring system, industrial-grade vibration sensors were installed on both drive-end and non-drive-end bearings. Edge computing units performed local data processing, enabling continuous tracking of multiple metrics such as vibration velocity RMS, peak values, and kurtosis. Within six months of operation, the system issued an early warning for outer-race bearing spalling. At that time, vibration velocity RMS rose from a baseline of 2.1 mm/s to 3.8 mm/s, accompanied by enhanced energy around a 4.5 kHz high-frequency resonance band. Maintenance teams scheduled a planned shutdown and replaced the bearing, avoiding unplanned downtime that would have caused daily production losses on the order of one million yuan.

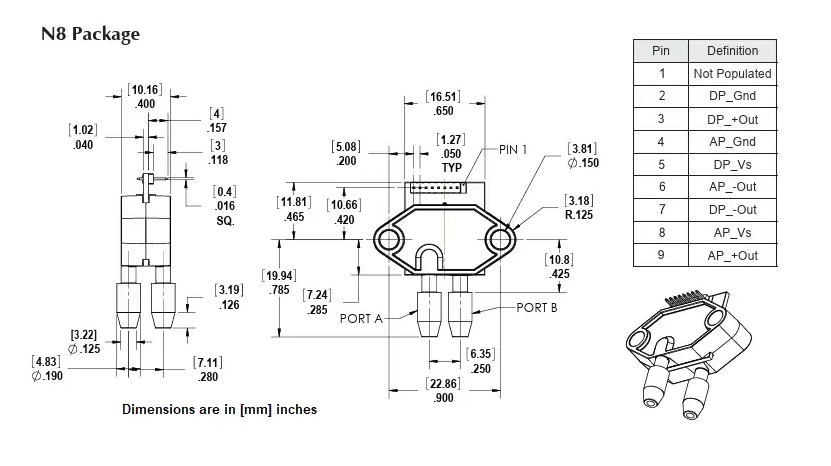

Sensor Requirements and Selection Considerations

Fan monitoring imposes strict requirements on vibration sensor performance. Key considerations include:

- Wide frequency response, typically covering 1 Hz–10 kHz, to capture both low-frequency structural vibration and high-frequency impact features.

- Good temperature stability and immunity to electromagnetic interference, especially in variable-frequency drive environments.

- Long-term reliability and appropriate ingress protection ratings, for example IP67.

Under harsh operating conditions, some sensors may suffer zero drift, signal distortion, or failure due to poor sealing or circuit design defects, potentially leading to incorrect diagnostics. Therefore, besides algorithms and platform capabilities, the hardware quality of the sensing layer determines the trustworthiness of the overall monitoring solution. Selecting vibration sensors with stable output characteristics validated in industrial environments is a prerequisite for reliable monitoring data.

Conclusion

Vibration monitoring remains a primary entry point for implementing fan health monitoring within industrial predictive maintenance frameworks. Reliable sensors, appropriate signal processing, and trend-based diagnostics together enable early fault detection and planned interventions, improving equipment availability and operational safety.

ALLPCB

ALLPCB