Choosing the right thermal pad thickness is crucial for effective heat management in electronic applications. Whether you're working on a high-performance computing device or an industrial system, the thickness of your thermal pad can make or break the thermal conductivity and overall performance of your setup. In this comprehensive guide, we'll walk you through how to determine the ideal thermal pad thickness for your specific needs, covering tools like a thermal pad thickness calculator, tips for optimal thermal pad compression, and methods for measuring thermal pad thickness. Let's dive into the details to ensure your components stay cool and efficient.

Why Thermal Pad Thickness Matters in Heat Management

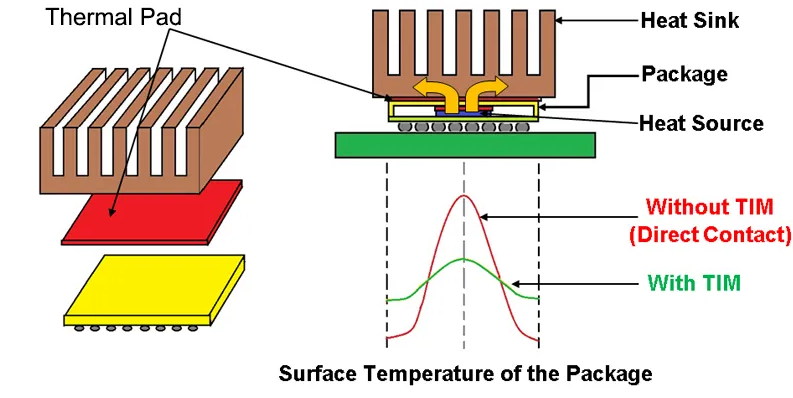

Thermal pads, also known as thermal gap fillers, are essential components in electronics that bridge the gap between heat-generating components (like CPUs, GPUs, or power transistors) and heat sinks or enclosures. Their primary role is to transfer heat efficiently while compensating for surface irregularities. However, if the thermal pad thickness isn't right, it can lead to poor heat transfer, increased thermal resistance, or even mechanical stress on components.

A pad that's too thick may not compress properly, leaving air gaps that hinder heat dissipation. On the other hand, a pad that's too thin might not fill the gap adequately or could over-compress, leading to stress on delicate parts. Striking the right balance is key to ensuring both thermal performance and component longevity.

Key Factors in Determining Thermal Pad Thickness

Before you can select the right thermal pad, you need to understand the factors that influence the ideal thickness for your application. Let's break down the main considerations.

1. Gap Distance Between Components

The first step in choosing a thermal pad is to measure the gap distance between the heat source and the heat sink or cooling solution. This distance represents the space that the thermal pad must fill to ensure proper contact and heat transfer. Typically, thermal pads are designed to be slightly thicker than the gap to allow for compression, which improves thermal conductivity by eliminating air pockets.

For example, if the measured gap is 1.5 mm, a thermal pad with a thickness of 2.0 mm might be recommended. When compressed by about 25%, the pad will conform to the surfaces, filling the gap perfectly without excessive stress.

2. Optimal Thermal Pad Compression

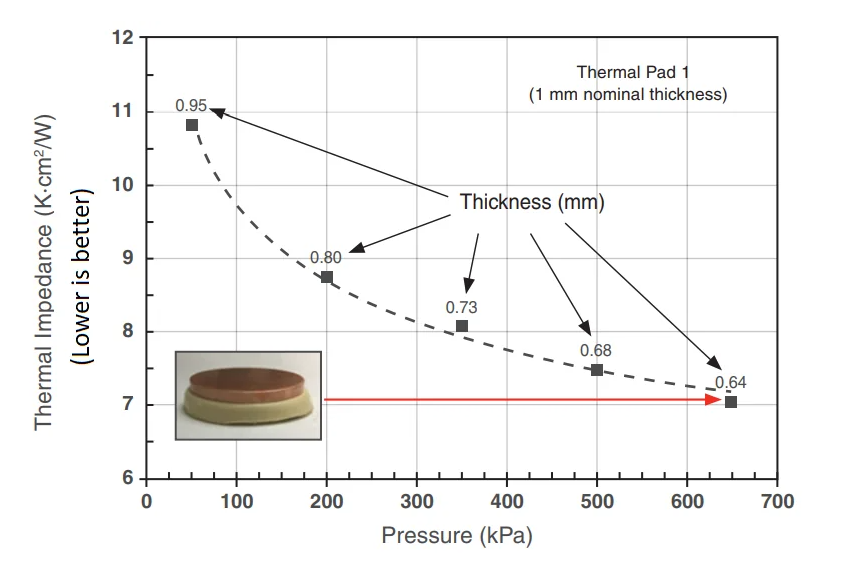

Compression is a critical aspect of thermal pad performance. Most thermal pads are designed to work best when compressed between 10% and 50% of their original thickness. This range ensures that the pad makes full contact with both surfaces, minimizing thermal resistance. According to industry insights, proper compression can reduce thermal resistance by up to 95%, making it a vital factor in heat management.

To achieve optimal thermal pad compression, select a pad that is thicker than the gap but within a range that allows for the recommended compression percentage. Over-compression can lead to mechanical stress, while under-compression can result in poor heat transfer. Balancing this is key to maximizing performance.

3. Material Properties of the Thermal Pad

Thermal pads come in various materials, such as silicone-based or non-silicone options, each with different compressibility and thermal conductivity ratings. Softer materials may require less compression to achieve good contact, while harder materials might need a more precise thickness match to avoid excessive stress. Always check the manufacturer's datasheet for specific recommendations on thickness and compression for the material you're using.

How to Measure Thermal Pad Thickness Accurately

Accurate measurement is the foundation of selecting the right thermal pad thickness. If you're replacing an existing pad or designing a new system, knowing how to measure thermal pad thickness is essential. Here's a step-by-step guide to get it right.

Tools You'll Need

- A clean, flat surface to place the components or pad.

- A digital or analog micrometer or caliper for precise measurements.

- The thermal pad or the components you'll be working with.

Steps for Measuring Thermal Pad Thickness

- Prepare the Surface: Ensure the surface is clean and free of debris to avoid measurement errors.

- Measure the Pad (if replacing): Place the thermal pad flat on the surface and use the caliper or micrometer to measure its thickness at multiple points. Thermal pads can vary slightly in thickness, so take an average for accuracy.

- Measure the Gap (if designing): If you're measuring the gap between components, assemble the heat source and heat sink without the pad. Use the caliper to measure the distance at several points to account for any unevenness.

- Record and Compare: Note down your measurements and use them to select a pad that is slightly thicker than the gap to allow for compression.

By taking precise measurements, you can avoid common pitfalls like choosing a pad that's too thick or too thin for the application.

Using a Thermal Pad Thickness Calculator for Precision

If manual measurements and calculations seem daunting, a thermal pad thickness calculator can simplify the process. These online tools or manufacturer-provided resources help you input key data like gap distance, desired compression percentage, and material type to recommend the ideal pad thickness.

For instance, some calculators allow you to enter a gap distance of 1.2 mm and a target compression of 20%. The tool might suggest a pad thickness of 1.5 mm to achieve the desired performance. While these calculators are helpful, always cross-check their recommendations with manufacturer guidelines to ensure compatibility with your specific setup.

Using a thermal pad thickness calculator saves time and reduces the risk of error, especially for complex assemblies with multiple components. Many industry resources offer free access to such tools, making them a valuable asset for engineers and hobbyists alike.

Understanding Thermal Pad Gap Filler Performance

Thermal pads are often referred to as thermal gap fillers because they are designed to fill uneven spaces between components. Their ability to conform to surface irregularities is what makes them so effective. However, the performance of a thermal gap filler depends heavily on choosing the right thickness.

A properly sized thermal gap filler ensures:

- Maximum Contact: The pad conforms to both surfaces, eliminating air gaps that increase thermal resistance.

- Even Pressure Distribution: The right thickness prevents uneven pressure that could damage components.

- Enhanced Heat Transfer: With optimal compression, the pad achieves its maximum thermal conductivity, often rated in W/m·K (watts per meter-kelvin). For example, high-performance pads can offer conductivity up to 8.0 W/m·K under ideal conditions.

When selecting a thermal gap filler, prioritize thickness alongside conductivity and softness to ensure it meets the demands of your application.

Thermal Pad Stress Analysis: Avoiding Mechanical Damage

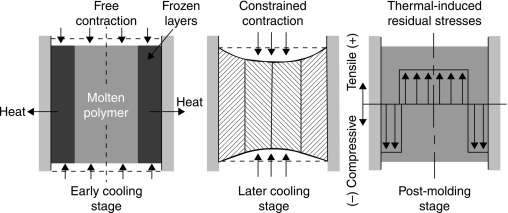

One often-overlooked aspect of thermal pad selection is the potential for mechanical stress on components. Thermal pad stress analysis involves evaluating how much force the pad exerts when compressed and whether that force could harm delicate parts like integrated circuits or connectors.

If a thermal pad is too thick for the gap, over-compression can lead to excessive stress, potentially cracking or deforming components. Conversely, a pad that's too thin might not provide enough cushioning, leading to uneven pressure distribution. To perform a basic stress analysis:

- Check Compression Force: Refer to the pad's datasheet for its compression force relaxation curve, which shows how much force it exerts at different compression levels.

- Assess Component Tolerance: Ensure the components in your assembly can withstand the expected force without damage.

- Test Under Load: If possible, assemble the setup and test for any signs of stress, such as warping or cracking, before finalizing the design.

By conducting a thermal pad stress analysis, you can prevent long-term reliability issues and ensure the safety of your electronic assembly.

Tips for Selecting the Right Thermal Pad Thickness

Now that we've covered the technical aspects, here are some practical tips to help you choose the ideal thermal pad thickness for your application:

- Always Measure Twice: Double-check your gap measurements to avoid errors that could lead to poor performance.

- Consult Manufacturer Data: Use the thermal pad's technical datasheet for guidance on recommended compression and thickness ranges.

- Consider Environmental Factors: Temperature fluctuations and vibrations can affect pad performance, so choose a thickness that accommodates these variables.

- Test in Real Conditions: If possible, test the pad in your actual setup to confirm it performs as expected under load.

- Balance Cost and Performance: Thicker pads or high-conductivity materials may cost more, so weigh the benefits against your budget.

Common Mistakes to Avoid When Choosing Thermal Pad Thickness

Even with the best intentions, it's easy to make mistakes when selecting thermal pad thickness. Here are some pitfalls to watch out for:

- Ignoring Compression Guidelines: Failing to account for the recommended 10-50% compression range can lead to inefficient heat transfer.

- Using Inaccurate Measurements: Relying on rough estimates instead of precise tools like calipers can result in the wrong pad size.

- Overlooking Stress Risks: Not considering the mechanical stress caused by over-compression can damage components over time.

- Choosing Based on Price Alone: Opting for the cheapest pad without evaluating its thickness or material properties can compromise performance.

Conclusion: Mastering Thermal Pad Thickness for Optimal Performance

Determining the ideal thermal pad thickness for your application doesn't have to be a daunting task. By carefully measuring the gap distance, aiming for optimal thermal pad compression, and using tools like a thermal pad thickness calculator, you can ensure efficient heat transfer and protect your components from stress. Whether you're using a thermal gap filler for a small device or a large industrial system, understanding factors like material properties and conducting a thermal pad stress analysis will lead to better results.

At ALLPCB, we’re committed to helping you achieve the best performance in your electronic designs. With the right approach to measuring thermal pad thickness and selecting the perfect size, you can keep your systems running cool and reliable. Follow the steps and tips outlined in this guide to make informed decisions and optimize your thermal management solutions.

ALLPCB

ALLPCB