If you're looking to ensure the reliability and efficiency of PCB motors, understanding how to test and validate them is crucial. This blog dives deep into the essentials of PCB motor testing and validation, focusing on key performance metrics and measurement techniques. Whether you're an engineer or a hobbyist, you'll find practical insights on how to evaluate PCB motor performance to achieve optimal results. Let’s explore the detailed processes, tools, and metrics that can help you ensure your PCB motors meet the highest standards.

What Are PCB Motors and Why Testing Matters

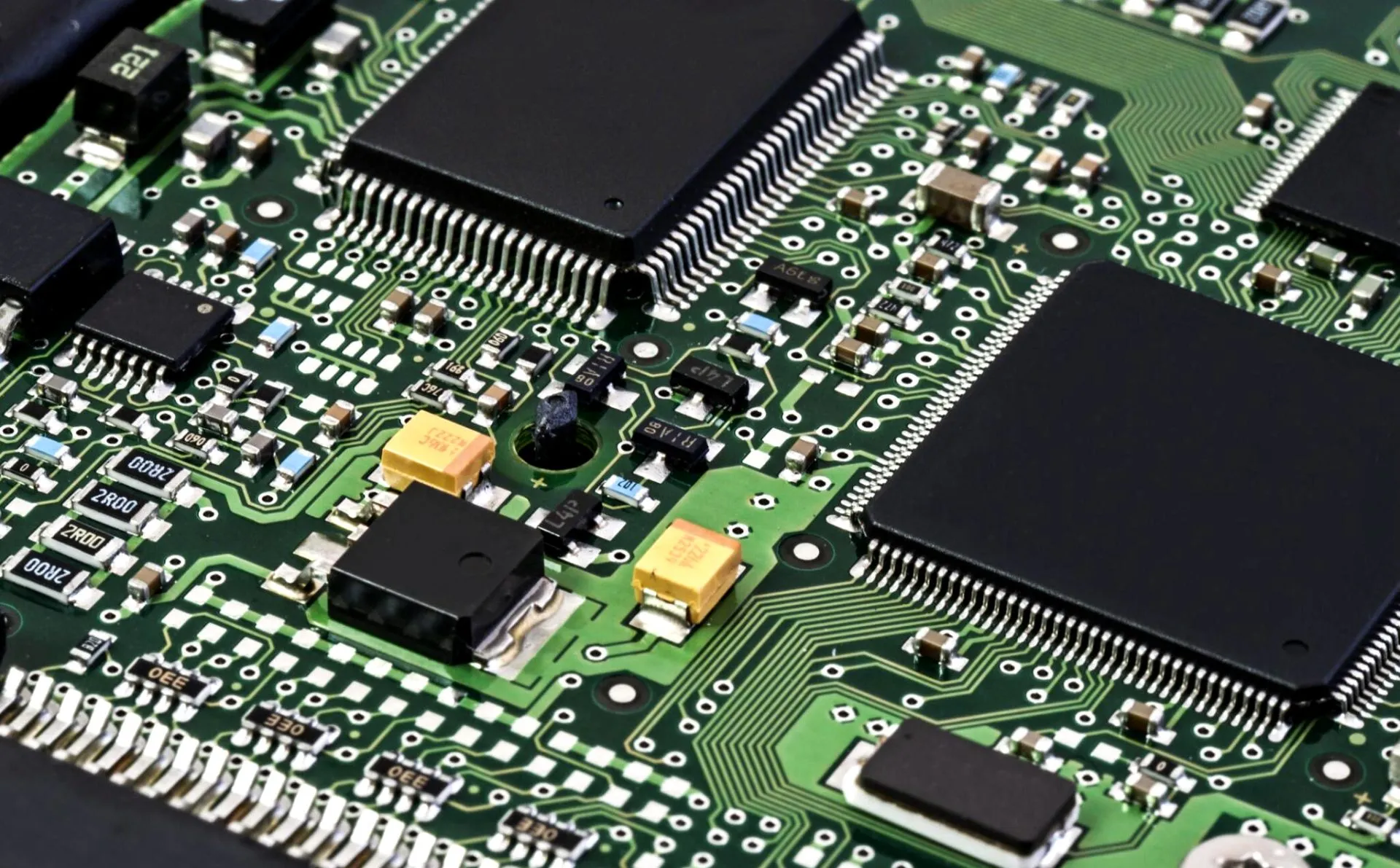

PCB motors, or printed circuit board motors, are innovative designs that integrate motor components directly onto a printed circuit board. Unlike traditional motors, these compact systems use the PCB itself as a structural or functional part of the motor, often reducing size and cost while enabling unique applications in electronics like drones, robotics, and small appliances. However, their unique design also means that testing and validation are critical to ensure they perform reliably under real-world conditions.

Testing PCB motors helps identify potential issues such as electrical failures, mechanical inefficiencies, or thermal problems before they impact a final product. Validation ensures that the motor meets design specifications and performs consistently over time. Without proper testing, you risk product failures, safety hazards, or costly redesigns. In this guide, we'll cover the performance metrics to track and the measurement techniques to apply for effective PCB motor testing and validation.

Key Performance Metrics for PCB Motor Testing

When evaluating PCB motors, certain performance metrics provide a clear picture of how well the motor operates. These metrics are essential for both initial testing and long-term validation. Below are the most critical ones to focus on during PCB motor performance analysis.

1. Torque Output

Torque is a measure of the rotational force a PCB motor can produce, typically expressed in Newton-meters (Nm) or ounce-inches (oz-in). For small PCB motors used in applications like miniature fans or drones, torque values might range from 0.01 Nm to 0.1 Nm. Testing torque involves using a dynamometer or a torque sensor to measure the force output under various load conditions. Low torque can indicate design flaws or insufficient power delivery through the PCB traces.

2. Rotational Speed (RPM)

Rotational speed, measured in revolutions per minute (RPM), determines how fast the motor spins. For PCB motors, RPM can vary widely, from 1,000 to 20,000 RPM, depending on the application. Use a tachometer or optical encoder to measure RPM during testing. Consistent speed under load is a sign of good motor health, while fluctuations may point to electrical or mechanical issues.

3. Efficiency

Efficiency is the ratio of mechanical output power to electrical input power, expressed as a percentage. A well-designed PCB motor might achieve efficiencies between 60% and 80%. To calculate efficiency, measure input voltage and current (using a multimeter) and compare it to the mechanical output (torque and speed). Low efficiency often results from excessive heat loss or poor electrical connections in the PCB layout.

4. Thermal Performance

PCB motors can generate significant heat due to their compact design and high current densities. Overheating can degrade components or cause failure. Use thermal imaging cameras or thermocouples to monitor temperatures during operation. Ideally, temperatures should stay below 85°C for most PCB materials. If temperatures exceed safe limits, consider redesigning for better heat dissipation, such as adding thermal vias or increasing copper thickness.

5. Current and Voltage Stability

Stable current and voltage are critical for consistent PCB motor performance. Measure these using a digital multimeter or oscilloscope to ensure they stay within the design specifications (e.g., 3.3V to 5V for many small motors). Spikes or drops in voltage can lead to erratic behavior or damage. For example, a motor rated for 5V should not experience fluctuations beyond ±0.5V during operation.

Measurement Techniques for PCB Motor Validation

Once you've identified the key metrics, the next step is applying the right measurement techniques to validate PCB motor performance. These methods ensure accurate data collection and help pinpoint issues during testing.

1. Electrical Testing

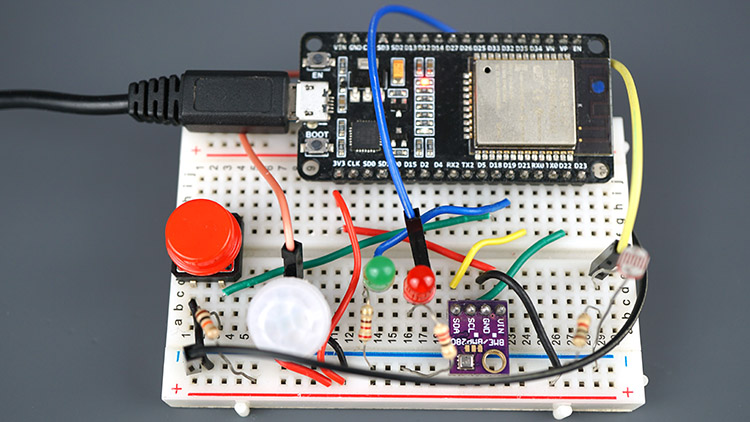

Electrical testing focuses on the motor’s power input and output. Use a multimeter to check voltage and current at various points on the PCB to ensure they match the design specs. For instance, if a motor is designed to draw 500mA at 5V, deviations beyond 10% could indicate a short circuit or open trace. Additionally, an oscilloscope can help analyze waveform patterns for any irregularities in the motor’s electrical behavior.

2. Mechanical Testing

Mechanical testing evaluates the motor’s physical performance, such as torque and speed. A dynamometer setup can measure torque by applying a controlled load to the motor shaft and recording the force. For speed, attach an optical encoder or use a laser tachometer to capture RPM data over time. These tests should be conducted at different operating conditions to simulate real-world usage.

3. Thermal Analysis

Thermal analysis is vital for PCB motors due to their integrated design. Use a thermal camera to map heat distribution across the board during operation. Pay attention to hotspots near motor windings or power traces, as these areas are prone to failure. For precise measurements, attach thermocouples to critical points and log temperature data over extended run times (e.g., 30 minutes at full load).

4. Vibration and Noise Testing

Vibration and noise can affect both performance and user experience. Use a vibration sensor or accelerometer to measure the motor’s vibration levels, typically in terms of displacement (mm) or acceleration (m/s2). Noise can be measured with a decibel meter; acceptable levels for small PCB motors are often below 40 dB. Excessive vibration or noise often indicates misalignment or unbalanced components.

5. Endurance Testing

Endurance testing simulates long-term operation to validate the motor’s durability. Run the motor continuously under typical load conditions for hours or days (e.g., 100 hours at 50% load) while monitoring key metrics like temperature, speed, and current. This helps identify potential wear or degradation in the PCB or motor components over time.

Best Practices for Effective PCB Motor Testing and Validation

To get the most reliable results from your PCB motor testing, follow these best practices. They help streamline the process and ensure accurate data for performance analysis.

1. Define Clear Testing Objectives

Before starting, outline what you aim to achieve with testing. Are you checking for basic functionality, long-term reliability, or specific performance metrics like torque? Clear objectives guide the selection of tools and methods, saving time and resources.

2. Use Calibrated Equipment

Ensure all testing equipment, such as multimeters, tachometers, and thermal cameras, is properly calibrated. Inaccurate tools can lead to misleading data. For example, a miscalibrated multimeter might show a voltage of 5.2V when the actual value is 4.8V, affecting your analysis.

3. Test Under Realistic Conditions

Simulate the actual operating environment of the PCB motor during testing. If the motor will be used in a drone operating at 25°C with variable loads, replicate those conditions as closely as possible. Testing in unrealistic scenarios can mask potential issues.

4. Document and Analyze Data

Record all test data systematically, including timestamps, conditions, and results. Use software tools to plot trends, such as RPM over time or temperature rise during operation. Analyzing this data helps identify patterns or anomalies that might not be obvious during testing.

5. Iterate Based on Findings

Testing isn’t a one-time task. Use the results to refine the PCB motor design or manufacturing process. For instance, if thermal testing reveals overheating near certain traces, consider increasing copper thickness or adding heat sinks in the next iteration.

Common Challenges in PCB Motor Testing and How to Overcome Them

Testing PCB motors isn’t without challenges. Their compact size and integration with the board can complicate measurements. Here are some common issues and solutions.

1. Limited Access to Test Points

Due to the small size of PCB motors, accessing test points for voltage or current measurements can be difficult. Use microprobes or design the PCB with dedicated test pads to simplify access during testing.

2. Heat Dissipation Issues

PCB motors often struggle with heat buildup. If testing shows excessive temperatures, improve the design by adding thermal vias, using higher-grade PCB materials, or integrating small heat sinks.

3. Interference from Nearby Components

Other components on the PCB can introduce electrical noise or interference, skewing test results. Shield sensitive areas or test the motor in isolation if possible to minimize external influences.

Tools and Equipment for PCB Motor Testing

Having the right tools is essential for accurate PCB motor measurement. Here’s a list of commonly used equipment:

- Multimeter: For measuring voltage, current, and resistance.

- Oscilloscope: For analyzing electrical waveforms and detecting irregularities.

- Tachometer: For measuring rotational speed (RPM).

- Dynamometer: For testing torque output.

- Thermal Camera: For identifying heat distribution and hotspots.

- Vibration Sensor: For assessing mechanical stability.

Investing in quality tools ensures precise data and reduces the risk of errors during PCB motor validation.

Conclusion: Ensuring Reliable PCB Motor Performance

Testing and validation are the cornerstones of building reliable PCB motors. By focusing on key performance metrics like torque, speed, efficiency, thermal behavior, and electrical stability, you can ensure your motors meet design goals and perform consistently. Applying the right measurement techniques—such as electrical testing, thermal analysis, and endurance testing—helps uncover potential issues before they become problems. With a structured approach and the best practices outlined in this guide, you can achieve accurate results and optimize your PCB motor designs for success.

At ALLPCB, we understand the importance of precision in every stage of PCB design and manufacturing. Whether you're prototyping a new PCB motor or scaling up production, thorough testing and validation are key to delivering high-quality results. Use these insights to enhance your testing processes and build motors that stand the test of time.

ALLPCB

ALLPCB