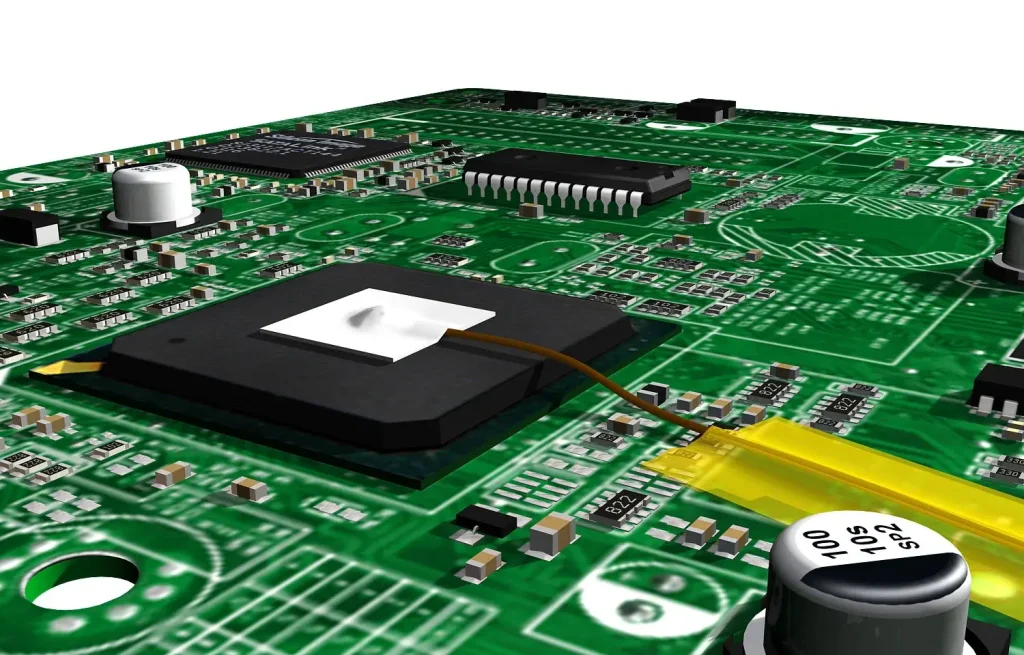

Thermal profiling is a critical process in PCB assembly that ensures efficient soldering, reliable performance, and minimal production defects. By carefully controlling temperature during the soldering process, manufacturers can achieve consistent assembly results and high-quality printed circuit boards (PCBs). In this comprehensive guide, we’ll explore what thermal profiling is, why it matters, and how it can optimize your PCB assembly process for better outcomes.

What is Thermal Profiling in PCB Assembly?

Thermal profiling refers to the process of monitoring and controlling the temperature changes a PCB undergoes during soldering, particularly in the reflow soldering stage of surface mount technology (SMT) assembly. This involves using sensors, such as thermocouples, to measure the temperature at various points on the PCB as it passes through a reflow oven. The data collected helps create a thermal profile—a detailed map of how heat is distributed and applied over time.

The goal of thermal profiling is to ensure that every component on the PCB is exposed to the right amount of heat for the correct duration. Too much heat can damage components, while too little heat can lead to poor solder joints and unreliable performance. By optimizing the temperature control during soldering, thermal profiling plays a vital role in reducing production defects and achieving consistent assembly results.

Why Thermal Profiling Matters for Efficient PCB Assembly

In PCB assembly, precision is everything. A small deviation in temperature can lead to significant issues, from weak solder joints to complete component failure. Thermal profiling addresses these challenges by providing a systematic approach to temperature control. Here are some key reasons why it’s essential for achieving efficient and reliable PCB assembly:

- Ensures Reliable Performance: Proper thermal profiling guarantees that solder joints are formed correctly, ensuring strong electrical connections and long-term reliability of the PCB.

- Reduces Production Defects: By maintaining optimal temperatures, thermal profiling minimizes common defects like tombstoning, bridging, or cold solder joints, which can compromise the board’s functionality.

- Improves Assembly Results: Consistent temperature control across the board leads to uniform soldering, enhancing the overall quality of the assembled PCB.

- Protects Components: Sensitive components, such as microcontrollers or capacitors, can be damaged by excessive heat. Thermal profiling helps avoid thermal stress and extends component lifespan.

Key Stages of a Thermal Profile in the Soldering Process

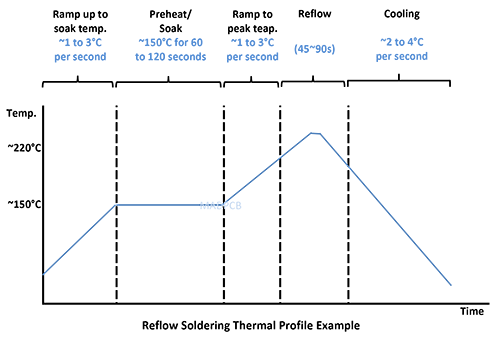

A thermal profile typically consists of several distinct stages, each with a specific purpose in the soldering process. Understanding these stages is crucial for achieving efficient PCB assembly. Let’s break them down:

1. Preheat Stage

The preheat stage gradually raises the temperature of the PCB to prepare it for soldering. This stage typically ranges from 25°C to around 150°C, depending on the solder paste used. The goal is to evaporate any moisture on the board and activate the flux in the solder paste, which helps clean the surfaces for better adhesion. A controlled preheat rate (often 1-3°C per second) prevents thermal shock to components.

2. Soak Stage

During the soak stage, the temperature is held steady, usually between 150°C and 180°C, for about 60-120 seconds. This allows the PCB and components to reach a uniform temperature, reducing the risk of uneven heating. Proper soaking minimizes defects like tombstoning, where components lift on one side due to uneven thermal expansion.

3. Reflow Stage

In the reflow stage, the temperature rises above the melting point of the solder paste, typically between 220°C and 250°C for lead-free solder. This is when the solder melts and forms joints between the components and the PCB pads. The time above liquidus (TAL)—the duration the solder remains molten—is critical and is usually kept between 30-90 seconds to ensure strong, reliable joints without overheating.

4. Cooling Stage

After reflow, the PCB enters the cooling stage, where the temperature drops at a controlled rate (often 2-4°C per second). Rapid cooling can cause thermal stress and cracks in solder joints, so a gradual decrease is essential. The cooling stage solidifies the solder, locking components in place for reliable performance.

How Thermal Profiling Enhances Temperature Control

Temperature control is at the heart of thermal profiling. Without precise management of heat, the soldering process can fail, leading to costly production defects. Here’s how thermal profiling contributes to better temperature control:

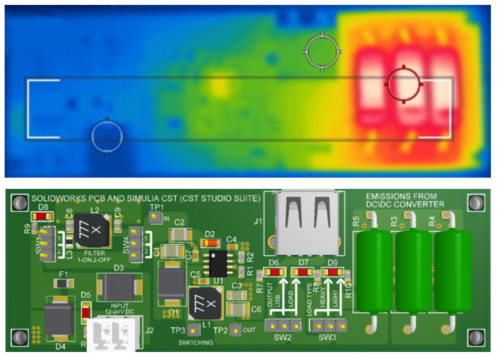

- Real-Time Monitoring: Thermocouples placed at strategic points on the PCB provide real-time data on temperature variations, allowing manufacturers to adjust oven settings as needed.

- Customized Profiles: Different PCBs and components require unique thermal profiles. For instance, a board with high-density components may need a slower preheat rate to avoid thermal shock, while a simpler board might tolerate faster heating. Thermal profiling software can help create tailored profiles for each assembly.

- Consistency Across Batches: By using a standardized thermal profile, manufacturers can replicate the same temperature conditions for every batch, ensuring consistent assembly results even in high-volume production.

For example, in a study of lead-free soldering processes, maintaining a peak temperature of 245°C with a TAL of 60 seconds resulted in a defect rate of less than 0.5% across 10,000 assembled units. Such data highlights the impact of precise temperature control on production quality.

Common Production Defects Caused by Poor Thermal Profiling

When thermal profiling is not done correctly, it can lead to a range of production defects that affect the PCB’s performance. Here are some common issues and how they relate to improper temperature control:

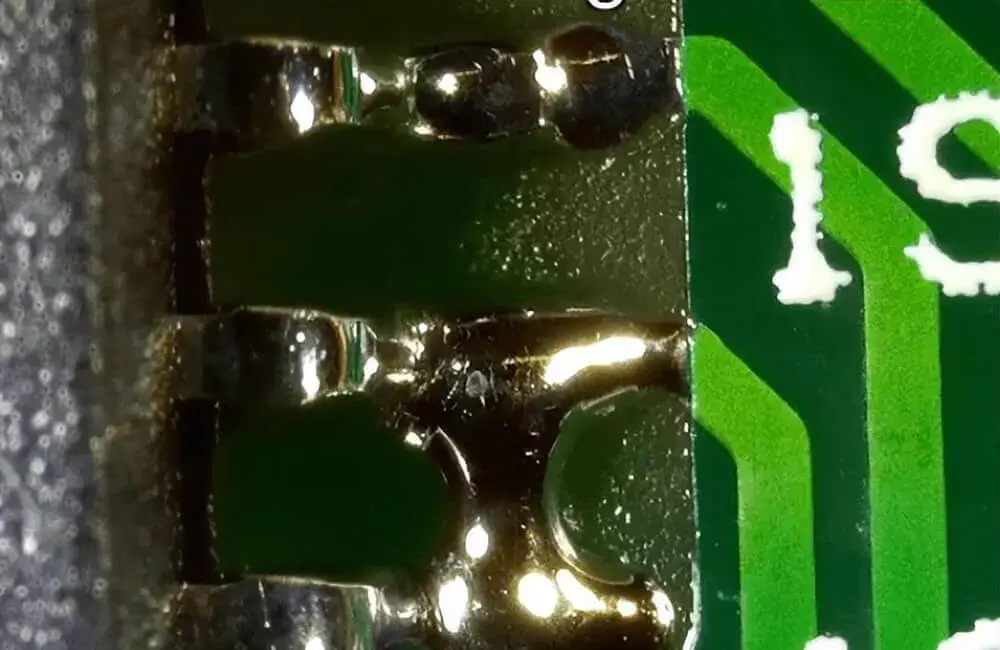

- Cold Solder Joints: If the temperature doesn’t reach the solder’s melting point or the TAL is too short, the solder may not fully bond, resulting in weak connections that can fail over time.

- Tombstoning: Uneven heating during the soak or reflow stage can cause components to lift on one side, resembling a tombstone. This often happens when one pad heats faster than the other.

- Solder Bridging: Excessive heat or prolonged TAL can cause solder to flow between adjacent pads, creating unwanted connections that short-circuit the board.

- Component Damage: Overheating during the reflow stage can burn sensitive components, leading to immediate failure or reduced lifespan.

By implementing accurate thermal profiling, these defects can be significantly reduced. For instance, maintaining a preheat rate of 2°C per second and a peak temperature within 5°C of the recommended value can cut defect rates by up to 70% in some production lines.

Best Practices for Effective Thermal Profiling

To achieve efficient PCB assembly through thermal profiling, follow these best practices for optimal temperature control and reliable performance:

- Use High-Quality Sensors: Invest in accurate thermocouples or other temperature sensors to gather precise data. Place them at multiple points on the PCB, including near sensitive components and high-density areas, to capture a complete thermal map.

- Test and Validate Profiles: Before full-scale production, run test boards through the reflow oven and analyze the thermal profile. Adjust settings to ensure the profile matches the solder paste and component specifications (e.g., peak temperature within 235-250°C for lead-free solder).

- Monitor Oven Performance: Regularly check the reflow oven for consistent heat distribution. Variations in conveyor speed or zone temperatures can skew the thermal profile and lead to defects.

- Leverage Software Tools: Use advanced thermal profiling software to analyze data and simulate profiles. These tools can predict potential issues and recommend adjustments for better assembly results.

- Train Your Team: Ensure that operators and engineers understand the importance of thermal profiling and know how to interpret data. A well-trained team can quickly address temperature-related issues during production.

Innovations in Thermal Profiling for PCB Assembly

The field of thermal profiling is evolving with new technologies that enhance temperature control and reduce production defects. Here are some recent innovations shaping the future of PCB assembly:

- Virtual Profiling: Advanced software now allows manufacturers to simulate thermal profiles without running physical test boards. This saves time and resources while still ensuring accurate temperature control.

- Automated Systems: Modern reflow ovens come equipped with built-in profiling tools that automatically adjust temperatures based on real-time data, minimizing human error.

- AI-Driven Analysis: Artificial intelligence is being used to analyze thermal profile data and predict potential defects before they occur. This proactive approach can significantly improve assembly results in high-volume production.

These innovations are making thermal profiling more accessible and effective, helping manufacturers achieve reliable performance even with complex PCB designs.

Conclusion: Mastering Thermal Profiling for Superior PCB Assembly

Thermal profiling is a cornerstone of efficient PCB assembly, enabling precise temperature control, reducing production defects, and ensuring reliable performance. By understanding the stages of a thermal profile, implementing best practices, and leveraging modern tools, manufacturers can achieve consistent assembly results that meet the highest quality standards.

Whether you’re assembling simple boards or complex, high-density designs, thermal profiling is the key to minimizing errors and maximizing efficiency in the soldering process. With the right approach, you can protect components, enhance solder joint quality, and deliver PCBs that perform reliably in any application.

Start optimizing your thermal profiling today to unlock the full potential of your PCB assembly process. With careful attention to temperature control, you’ll see fewer defects, better performance, and improved production outcomes.

ALLPCB

ALLPCB