When it comes to printed circuit board (PCB) design, one of the most critical factors to consider is the copper foil thickness. This aspect directly impacts the board's performance, durability, and cost. At ALLPCB, we understand the importance of choosing the right copper foil thickness for your PCB projects. So, what is the standard copper foil thickness in PCB design? The most common standard is 1 oz per square foot, which translates to a thickness of about 1.37 mils (or 35 micrometers). This is often the default choice for many designs due to its balance of conductivity, cost, and ease of manufacturing.

In this comprehensive guide, we'll dive deeper into the world of copper foil thickness in PCB design. We'll explore why 1 oz is the industry standard, how different thicknesses affect performance, and how to choose the right copper weight for your specific application. Whether you're a beginner or an experienced engineer, this article will provide valuable insights to help you make informed decisions for your next PCB project with ALLPCB.

What Is Copper Foil Thickness in PCB Design?

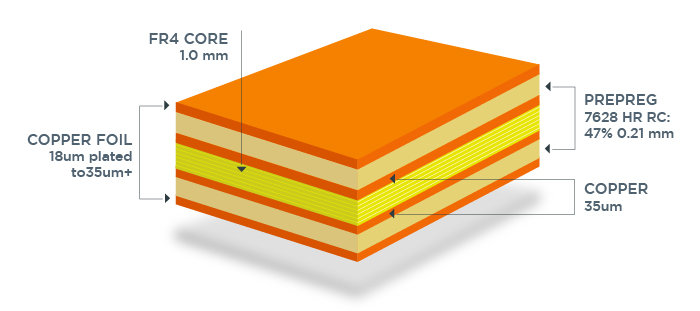

Copper foil thickness refers to the amount of copper used on the conductive layers of a PCB. These layers form the traces and pads that carry electrical signals and power across the board. The thickness of the copper is typically measured in ounces per square foot (oz/ft2), which describes the weight of copper spread over a one-square-foot area. This measurement directly correlates to the actual thickness of the copper layer.

For instance, 1 oz of copper per square foot results in a thickness of approximately 1.37 mils, or 35 micrometers (μm). This unit of measurement might seem unusual, but it’s a long-standing standard in the PCB industry because it’s easier to measure copper by weight during manufacturing. The thicker the copper, the more current it can carry, but it also increases the cost and complexity of production.

Why Is 1 oz Copper the Standard in PCB Design?

The 1 oz copper foil thickness, equivalent to 35 μm, is widely regarded as the industry standard for most PCB designs. This popularity stems from several practical reasons:

- Balanced Performance: A 1 oz copper layer provides sufficient current-carrying capacity for most standard electronic applications, such as consumer electronics, while keeping signal integrity intact.

- Cost-Effectiveness: Thicker copper layers increase material and processing costs. The 1 oz thickness strikes a balance between performance and affordability, making it ideal for mass production.

- Ease of Manufacturing: PCB fabrication processes, including etching and plating, are optimized for 1 oz copper. Thicker layers can complicate these processes, leading to potential defects or higher costs.

- Compatibility: Most PCB design software and manufacturing standards default to 1 oz copper unless specified otherwise, ensuring compatibility across tools and suppliers.

At ALLPCB, we often recommend starting with 1 oz copper for general-purpose designs. It’s a safe choice for many applications, from simple single-layer boards to more complex multilayer designs.

Common Copper Foil Thickness Options in PCB Design

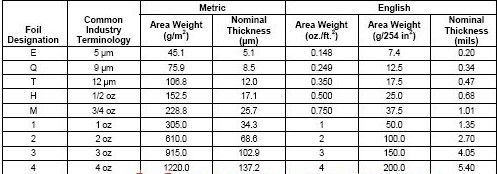

While 1 oz copper is the standard, other thicknesses are available depending on the specific needs of your project. Here’s a breakdown of the most common copper foil thicknesses used in PCB design:

- 0.5 oz (17.5 μm or 0.69 mils): This is a thinner copper layer often used in low-power or high-density designs where space is limited. It’s less expensive but can only handle lower currents.

- 1 oz (35 μm or 1.37 mils): As mentioned, this is the standard and most commonly used thickness, suitable for a wide range of applications.

- 2 oz (70 μm or 2.74 mils): This thicker copper is used in designs requiring higher current-carrying capacity, such as power electronics or automotive applications.

- 3 oz and above (105 μm or 4.11 mils and up): Heavy copper layers are used in specialized applications like industrial equipment or high-power systems where significant current and heat dissipation are involved.

Choosing the right thickness depends on factors like current requirements, thermal management, and budget. ALLPCB supports a wide range of copper thicknesses to meet the diverse needs of our customers, ensuring your design performs as expected.

How Copper Foil Thickness Impacts PCB Performance

The thickness of the copper foil in a PCB directly affects several key performance aspects. Understanding these effects can help you make better design decisions. Let’s explore the main areas of impact:

1. Current-Carrying Capacity

Thicker copper layers can carry more current without overheating. For example, a 1 oz copper trace that is 10 mils wide can safely carry around 1.2 amps of current at a temperature rise of 10°C, based on standard IPC-2152 calculations. If your design requires more current, you might need to increase the copper thickness to 2 oz or wider traces to handle the load without risking damage.

2. Thermal Management

Copper is an excellent conductor of heat as well as electricity. Thicker copper layers can dissipate heat more effectively, which is crucial in high-power applications. For instance, in a power supply PCB, using 2 oz or 3 oz copper can prevent hotspots and improve overall reliability by spreading heat more evenly across the board.

3. Signal Integrity

In high-frequency designs, copper thickness can influence signal integrity. Thinner copper (like 0.5 oz) is often used in RF (radio frequency) applications to minimize signal loss and maintain impedance control. For a 50-ohm impedance line on a standard FR-4 substrate, a thinner copper layer might require narrower traces, which can be challenging to manufacture but critical for performance.

4. Manufacturing Challenges

Thicker copper layers are harder to etch precisely, which can lead to issues with fine-pitch traces or small vias. For designs with tight tolerances, sticking to 1 oz copper often ensures better manufacturing yields. At ALLPCB, we use advanced fabrication techniques to handle a variety of copper thicknesses while maintaining high precision.

How to Choose the Right Copper Foil Thickness for Your PCB

Selecting the appropriate copper foil thickness for your PCB design involves balancing performance requirements with cost and manufacturability. Here are some practical steps to guide your decision:

- Determine Current Requirements: Use a current calculator or refer to standards like IPC-2152 to estimate the current your traces need to carry. If the current exceeds what 1 oz copper can handle, consider increasing the thickness or widening the traces.

- Evaluate Thermal Needs: If your design generates significant heat, thicker copper (2 oz or more) can help manage thermal dissipation. This is especially important for power electronics or LED applications.

- Consider Signal Frequency: For high-frequency or RF designs, thinner copper might be necessary to control impedance and reduce signal loss. Consult with your PCB manufacturer to ensure compatibility with your design goals.

- Budget Constraints: Thicker copper increases material and processing costs. If cost is a major concern, optimize your design to work with 1 oz copper wherever possible.

- Consult with Your Manufacturer: At ALLPCB, our team of experts is ready to assist you in selecting the right copper thickness. We can provide recommendations based on your specific design files and application needs.

ALLPCB’s Role in Supporting Your Copper Thickness Needs

At ALLPCB, we are committed to providing high-quality PCB manufacturing services tailored to your unique requirements. Whether you need the standard 1 oz copper for a cost-effective design or a heavy 3 oz copper for a high-power application, we’ve got you covered. Our state-of-the-art facilities and experienced engineers ensure that your boards are fabricated with precision, regardless of the copper thickness you choose.

We also offer flexible options for copper thickness in both prototype and mass production runs. Our online ordering system allows you to specify your desired copper weight easily, and our support team is always available to answer any questions or provide guidance. With ALLPCB, you can trust that your PCB design will be brought to life with the highest standards of quality and reliability.

Common Misconceptions About Copper Foil Thickness

There are several myths and misunderstandings about copper foil thickness in PCB design. Let’s clear up a few of the most common ones:

- Thicker Copper Is Always Better: While thicker copper can handle more current, it’s not always necessary. Over-specifying copper thickness can unnecessarily increase costs without providing significant benefits.

- Thin Copper Is Only for Low-Power Designs: While thinner copper is used in low-power applications, it’s also critical for high-frequency designs where signal integrity is a priority.

- Copper Thickness Doesn’t Affect Design Software: Many PCB design tools require you to input copper thickness to calculate impedance and trace widths accurately. Ignoring this can lead to design errors.

Understanding these nuances can save time and money while ensuring your PCB performs as intended. ALLPCB is here to help clarify any doubts and provide the expertise you need for a successful design.

Conclusion: Making the Right Choice for Copper Foil Thickness with ALLPCB

Copper foil thickness is a fundamental aspect of PCB design that influences everything from current capacity to thermal management and signal integrity. While 1 oz copper remains the standard for most applications due to its versatility and cost-effectiveness, other thicknesses like 0.5 oz, 2 oz, or even heavier options are available for specialized needs. By carefully considering factors like current requirements, thermal performance, and budget, you can select the ideal copper thickness for your project.

At ALLPCB, we pride ourselves on supporting engineers and designers with top-tier PCB manufacturing services. Whether you’re working on a simple prototype or a complex multilayer board, our team is ready to assist with choosing the right copper foil thickness and ensuring your design is manufactured to perfection. Trust ALLPCB to be your partner in bringing innovative electronic designs to life.

ALLPCB

ALLPCB