Introduction

Silicon carbide (SiC) power devices are becoming a transformative technology in power electronics. Their superior physical properties offer opportunities to improve energy efficiency, reduce system size, and increase reliability. This article examines the fundamentals of SiC power devices, their advantages, main application areas, challenges, and future trends.

1. Fundamentals of SiC Power Devices

Silicon carbide is a wide bandgap semiconductor with physical and chemical properties superior to silicon (Si), including a higher critical breakdown field, greater thermal conductivity, higher allowable operating temperature, and faster switching speed. These characteristics make SiC devices more efficient and better performing than conventional silicon devices in high-voltage, high-frequency, and high-temperature environments.

2. Advantages of SiC Power Devices

- High efficiency: SiC devices exhibit lower conduction and switching losses compared with silicon devices, enabling higher overall system efficiency.

- High-frequency operation: Faster switching speeds make SiC devices well suited for high-frequency applications, which helps reduce the size and cost of passive components such as transformers and inductors.

- High-temperature stability: SiC devices can operate reliably at temperatures up to about 200°C, whereas traditional silicon devices typically have lower maximum operating temperatures.

- High-voltage capability: SiC devices can withstand higher voltages, which can reduce insulation requirements and simplify system designs.

3. Main Application Areas

SiC power devices show significant potential across multiple fields:

- Electric vehicles (EVs): used in traction inverters, chargers, and DC-DC converters to improve efficiency, reduce energy loss, and increase driving range.

- Renewable energy systems: deployed in solar inverters and wind power converters to improve energy conversion efficiency and system stability.

- Power transmission and distribution: applied in high-voltage direct current (HVDC) transmission systems and solid-state power transformers to improve efficiency and reliability.

- Industrial and consumer equipment: used in power supplies, variable frequency drives, and high-efficiency motor drives to reduce system size and extend product life.

4. Challenges

Despite clear technical advantages and application potential, broader adoption of SiC power devices faces several challenges:

- High cost: SiC materials and devices are currently more expensive than silicon counterparts, although costs have been decreasing with technology improvements and larger production volumes.

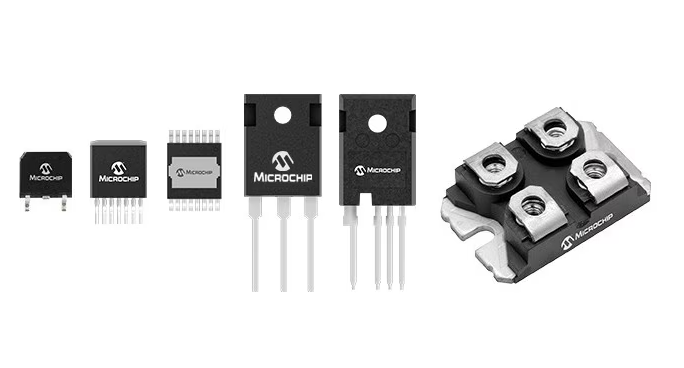

- Packaging and thermal management: Because SiC devices can carry higher currents and voltages, advanced packaging techniques and thermal solutions are required to maintain stability and reliability.

- Design and testing: High-performance SiC devices require power electronics designers to adopt new design methodologies and testing standards.

5. Future Development Trends

With ongoing research and technological progress, SiC power devices are expected to see wider adoption. Key trends include:

- Technical innovation: Continued advances in materials and manufacturing processes will improve SiC performance and reduce costs.

- Application expansion: As costs fall and performance improves, SiC devices will be used in an increasing range of applications, potentially including more consumer electronics products.

- Standardization and certification: Establishing industry standards and testing certification systems will be important to support commercial deployment of SiC devices.

Conclusion

SiC power devices, owing to their superior performance and efficiency, represent an important trend in power electronics. While challenges remain, technological advances and expanding application domains suggest that SiC power devices will play an increasingly significant role in future power electronic systems, supporting more efficient and environmentally friendly energy use.

ALLPCB

ALLPCB