Choosing the right PCB materials for renewable energy applications is crucial for ensuring performance, durability, and efficiency in harsh environments. Whether you're designing for solar inverters, wind turbine controllers, or energy storage systems, factors like high temperature resistance, dielectric properties, and long-term reliability play a big role. In this blog, we'll explore how to make informed decisions on PCB material selection, focusing on high-temperature options, alternatives to standard materials like FR4, and the importance of dielectric properties for renewable energy systems.

Let’s dive into the details of selecting PCB materials tailored for renewable energy applications, ensuring your designs can withstand challenging conditions while maintaining optimal functionality.

Why PCB Material Selection Matters in Renewable Energy

Renewable energy systems, such as solar panels, wind turbines, and battery storage units, operate in environments that often involve extreme temperatures, humidity, and mechanical stress. The printed circuit boards (PCBs) used in these systems must be robust enough to handle these conditions without failing. Poor material choices can lead to thermal breakdown, signal loss, or even complete system failure, which can be costly in terms of downtime and repairs.

PCB material selection directly impacts the efficiency of power conversion, signal integrity, and the overall lifespan of renewable energy devices. For instance, materials with low thermal conductivity can overheat in high-power applications like solar inverters, while poor dielectric properties can cause signal interference in control systems. That’s why understanding the specific demands of renewable energy applications is the first step in choosing the right materials.

Key Factors in PCB Material Selection for Renewable Energy

When selecting PCB materials for renewable energy applications, several critical factors must be considered. These include thermal performance, dielectric properties, mechanical strength, and environmental resistance. Below, we break down these factors to help guide your decision-making process.

1. High Temperature Resistance for Harsh Environments

Renewable energy systems often operate in outdoor or industrial settings where temperatures can fluctuate widely. For example, solar inverters in desert regions may face ambient temperatures exceeding 50°C (122°F), while internal components generate additional heat. Standard PCB materials may not withstand such conditions, leading to delamination or loss of electrical properties.

High-temperature PCB materials are designed to handle these extremes. They typically have a higher glass transition temperature (Tg), which is the point at which a material shifts from a rigid to a more flexible state. For instance, materials with a Tg of 170°C or higher are often recommended for applications where sustained high temperatures are expected. This ensures the PCB remains stable and functional even under thermal stress.

2. Dielectric Properties for Signal Integrity

Dielectric properties, such as the dielectric constant (Dk) and dissipation factor (Df), are critical for maintaining signal integrity in renewable energy systems. The dielectric constant determines how much electrical energy a material can store, while the dissipation factor indicates energy loss as heat. In high-frequency applications like wind turbine control systems, materials with a low Dk (typically between 2.2 and 3.5) and low Df (below 0.005) are preferred to minimize signal loss and ensure efficient power transmission.

For example, in a solar inverter operating at switching frequencies above 100 kHz, a material with poor dielectric properties can cause significant energy losses, reducing overall system efficiency. Choosing a material with stable dielectric properties across a wide temperature range is essential for reliable performance.

3. Mechanical Strength and Durability

Renewable energy equipment often faces mechanical stress from vibrations, wind, or installation handling. PCBs in wind turbines, for instance, must endure constant vibrations without cracking or losing connections. Materials with high mechanical strength and low coefficient of thermal expansion (CTE) are ideal, as they resist warping or cracking when exposed to temperature changes or physical stress.

A low CTE, ideally below 15 ppm/°C, ensures that the PCB expands and contracts minimally with temperature fluctuations, preventing solder joint failures. This is particularly important in energy storage systems where long-term reliability is a priority.

4. Environmental Resistance

Outdoor renewable energy systems are exposed to moisture, UV radiation, and chemical contaminants. PCB materials must resist corrosion and degradation under these conditions. Materials with high moisture resistance and low water absorption (below 0.2%) help prevent electrical shorts and maintain performance in humid environments, such as coastal wind farms.

Common PCB Materials for Renewable Energy Applications

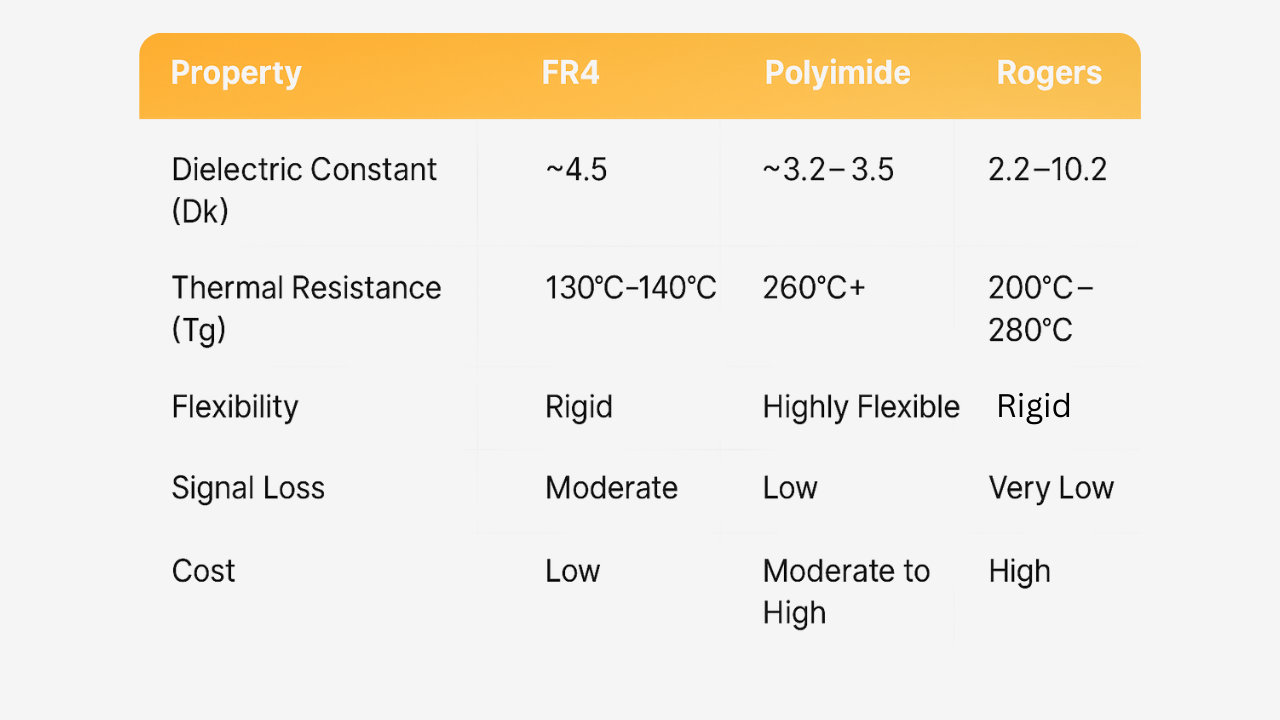

Understanding the properties of different PCB materials is key to making the right choice. Below, we discuss the most common materials used in renewable energy applications, including the widely used standard options and specialized alternatives for high-performance needs.

1. FR4: The Standard Choice and Its Limitations

FR4 is the most commonly used PCB material due to its affordability and versatility. It offers a good balance of electrical insulation, mechanical strength, and thermal resistance, with a Tg typically around 130-140°C. FR4 also has a dielectric constant of about 4.5 at 1 MHz, making it suitable for many low- to medium-frequency applications.

However, FR4 has limitations in high-temperature and high-frequency environments. Its thermal conductivity is relatively low (around 0.3 W/m·K), which can lead to overheating in high-power renewable energy systems. Additionally, its dielectric properties degrade at frequencies above 1 GHz, making it less ideal for advanced control systems in modern renewable energy setups.

2. FR4 Alternatives for High-Temperature and High-Frequency Needs

For applications where FR4 falls short, several alternatives offer superior performance in high-temperature and high-frequency conditions. These materials are often used in renewable energy systems that demand enhanced reliability and efficiency.

- High-Tg FR4 Variants: These are modified versions of standard FR4 with a Tg of 170°C or higher. They provide better thermal stability for applications like solar inverters, where moderate heat resistance is needed without significantly increasing costs.

- Polyimide Materials: Known for exceptional thermal resistance, polyimide materials can operate at temperatures up to 260°C. They also offer excellent mechanical flexibility, making them suitable for flexible PCBs in compact renewable energy devices. Their dielectric constant is around 3.5, and they maintain stability in humid conditions.

- PTFE-Based Materials: Polytetrafluoroethylene (PTFE) materials are ideal for high-frequency applications due to their low dielectric constant (around 2.1-2.5) and low dissipation factor (below 0.002). While more expensive, they are often used in advanced renewable energy control systems where signal integrity is critical.

Matching PCB Materials to Specific Renewable Energy Applications

Different renewable energy systems have unique requirements, and PCB material selection should align with these needs. Below are some examples of how to match materials to specific applications.

1. Solar Energy Systems

Solar inverters and charge controllers require materials that can handle high temperatures and power loads. High-Tg FR4 or polyimide materials are often recommended due to their thermal stability and ability to manage heat dissipation in compact designs. For high-efficiency inverters operating at high frequencies, PTFE-based materials may be necessary to minimize signal loss.

2. Wind Energy Systems

Wind turbine control systems face mechanical stress from vibrations and environmental exposure. Materials with high mechanical strength and low CTE, such as polyimide or reinforced FR4, are ideal. Additionally, low dielectric loss materials are crucial for maintaining signal integrity in high-frequency communication circuits used for turbine monitoring.

3. Energy Storage Systems

Battery management systems (BMS) in energy storage units require materials with excellent thermal management and long-term reliability. High-Tg FR4 or polyimide materials can handle the heat generated by high-current applications while resisting degradation over time.

How Dielectric Properties Impact Renewable Energy PCB Performance

Dielectric properties are often overlooked but play a vital role in the performance of renewable energy PCBs. A material’s dielectric constant affects how signals propagate through the board, while the dissipation factor influences energy loss. For high-frequency applications, such as those found in modern renewable energy control systems, selecting a material with a stable and low dielectric constant is critical.

For instance, in a solar inverter switching at 200 kHz, a material with a dielectric constant of 4.5 (like standard FR4) may introduce significant signal delay and loss compared to a material with a Dk of 2.2. Over time, this can reduce the system’s efficiency and increase operating costs. By prioritizing materials with optimized dielectric properties, designers can improve performance and reliability.

Tips for Selecting the Right PCB Material

To ensure you choose the best PCB material for your renewable energy application, follow these practical tips:

- Evaluate Operating Conditions: Assess the temperature range, humidity, and mechanical stress your PCB will face. Choose materials with properties that match or exceed these requirements.

- Prioritize Thermal Management: Opt for materials with high thermal conductivity or high Tg if your system generates significant heat.

- Consider Frequency Requirements: For high-frequency applications, select materials with low dielectric constants and dissipation factors to minimize signal loss.

- Balance Cost and Performance: While advanced materials offer superior properties, they come at a higher cost. Weigh the benefits against your budget to find the best fit.

- Test Under Real Conditions: Before full-scale production, prototype your design with the chosen material and test it under simulated operating conditions to ensure reliability.

Future Trends in PCB Materials for Renewable Energy

As renewable energy technologies advance, so do the materials used in PCB manufacturing. Emerging materials with enhanced thermal conductivity, such as ceramic-filled composites, are being developed to handle even higher power densities. Additionally, eco-friendly PCB materials made from bio-based resins are gaining attention as the industry moves toward sustainable practices.

Another trend is the integration of advanced dielectric materials for next-generation renewable energy systems. These materials aim to support higher frequencies and faster data transmission, which are essential for smart grids and IoT-enabled energy systems. Staying informed about these developments can help designers future-proof their projects.

Conclusion

Selecting the right PCB materials for renewable energy applications is a critical step in ensuring the reliability, efficiency, and longevity of your systems. By considering factors like high-temperature resistance, dielectric properties, mechanical strength, and environmental durability, you can make informed choices that meet the unique demands of solar, wind, and energy storage systems.

While standard materials like FR4 are suitable for many applications, alternatives such as high-Tg FR4, polyimide, and PTFE-based materials offer enhanced performance for challenging conditions. Understanding the specific needs of your project and matching them with the right material properties will lead to better outcomes and more efficient renewable energy solutions.

At ALLPCB, we’re committed to supporting your renewable energy projects with high-quality PCB solutions tailored to your requirements. Whether you need guidance on material selection or assistance with design and manufacturing, our expertise is here to help you succeed in building sustainable energy systems.

ALLPCB

ALLPCB