When it comes to selecting indicator lights for automotive applications, durability and reliability are non-negotiable. Automotive indicator lights, such as LED car indicators, must withstand harsh conditions like vibrations, extreme temperatures, and constant use while maintaining consistent performance. For engineers and manufacturers, choosing the right components—think vibration resistant LEDs, automotive grade LEDs, and extended temperature range LEDs—ensures safety, longevity, and compliance with industry standards. In this comprehensive guide, we’ll dive into the key factors to consider, the benefits of modern LED technology, and practical tips for selecting the best indicator lights for your automotive projects.

Why Durability and Reliability Matter in Automotive Indicator Lights

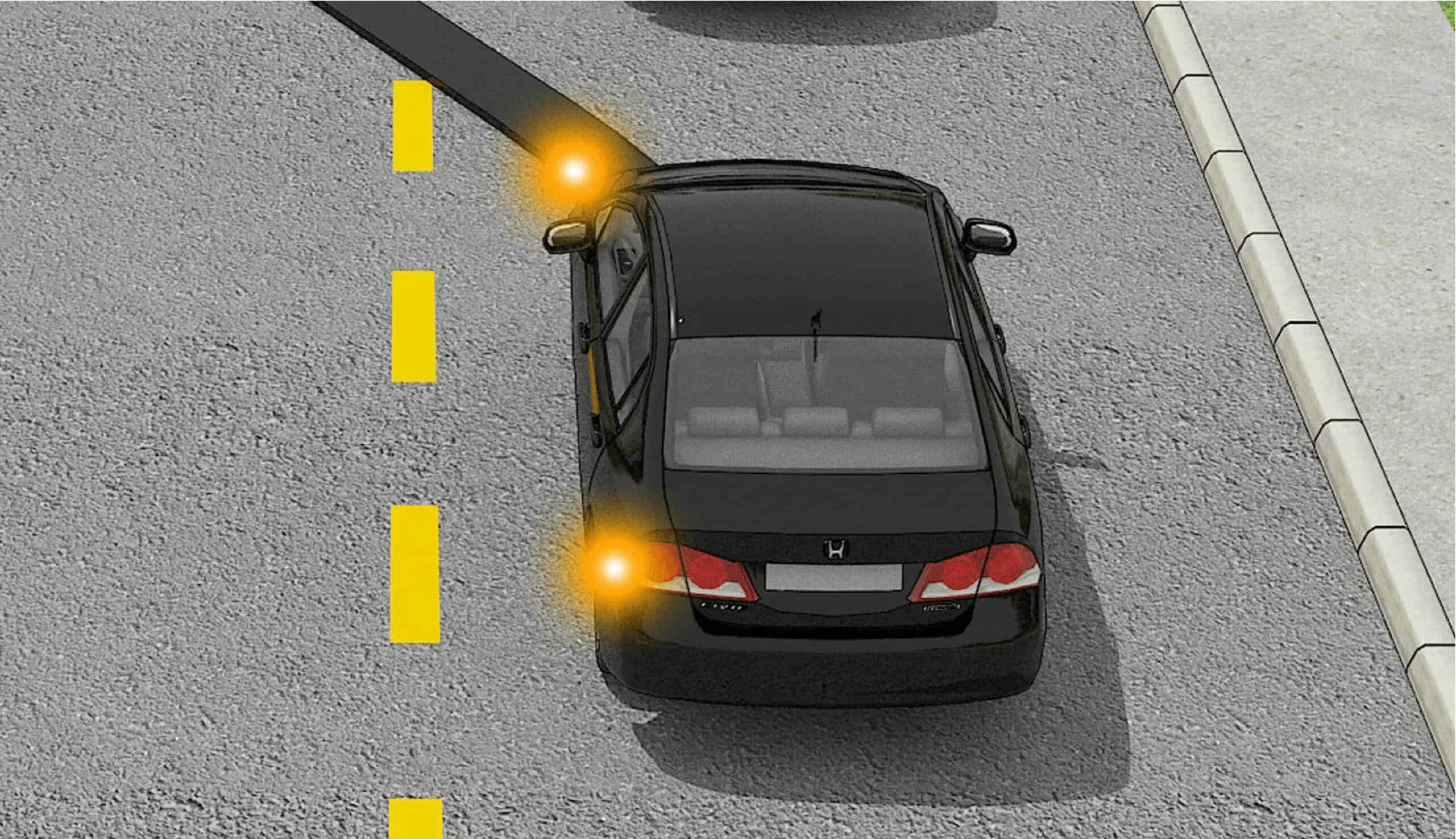

In the automotive world, indicator lights play a critical role in communication and safety. They signal turns, hazards, brake actions, and other vital information to drivers and pedestrians. A failure in these systems can lead to accidents or costly repairs. That’s why durability and reliability are at the forefront of design considerations. Automotive environments expose components to intense vibrations from rough roads, temperature swings from freezing winters to scorching summers, and constant on-off cycling. Selecting indicator lights built to endure these challenges is essential for performance and safety.

Key Factors to Consider When Choosing Automotive Indicator Lights

Selecting the right indicator lights for automotive applications involves evaluating several technical and environmental factors. Let’s break down the most important considerations to ensure you prioritize durability and reliability.

1. Vibration Resistance for Long-Term Stability

Vehicles are constantly in motion, often on uneven terrain, which subjects components to significant vibrations. Standard indicator lights may crack, loosen, or fail under such stress. This is where vibration resistant LEDs shine. These LEDs are designed with robust housing and secure mounting mechanisms to prevent damage. For instance, many vibration resistant LEDs are tested to withstand frequencies up to 200 Hz and accelerations of 10G, ensuring they remain operational even on the roughest roads.

When selecting vibration resistant LEDs, look for products with reinforced internal structures and shock-absorbing materials. These features minimize the risk of filament or connection failures, extending the lifespan of the indicator light in demanding conditions.

2. Automotive Grade LEDs for Industry Compliance

Not all LEDs are created equal, especially in the automotive sector. Automotive grade LEDs are specifically engineered to meet strict industry standards, such as those set by the Automotive Electronics Council (AEC-Q101 for LEDs). These standards test components for reliability under thermal stress, humidity, and mechanical shock. Choosing automotive grade LEDs ensures that your indicator lights can handle the rigors of vehicle operation without premature failure.

Automotive grade LEDs often feature enhanced thermal management systems to dissipate heat effectively, preventing performance degradation. They are also designed to resist corrosion from moisture and road salts, which is crucial for exterior indicator lights exposed to the elements.

3. Extended Temperature Range LEDs for Extreme Conditions

Automotive indicator lights must function in a wide range of temperatures, from below freezing to over 100°C near engine compartments. Extended temperature range LEDs are built to operate reliably in these extremes. Many of these LEDs are rated for operation between -40°C and +125°C, ensuring consistent brightness and functionality whether the vehicle is in an icy tundra or a desert highway.

For engineers, selecting extended temperature range LEDs means fewer worries about thermal expansion, material degradation, or reduced light output in harsh climates. Look for LEDs with datasheets specifying their temperature ratings and test conditions to confirm they meet your project’s needs.

4. Energy Efficiency and Brightness of LED Car Indicators

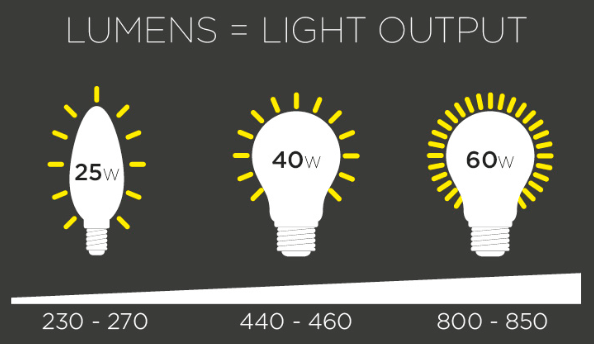

LED car indicators have become the go-to choice over traditional incandescent bulbs due to their superior energy efficiency and brightness. LEDs consume up to 80% less power than halogen bulbs, reducing the load on a vehicle’s electrical system and improving fuel efficiency. Additionally, they provide brighter and more focused light output, often exceeding 100 lumens per watt, which enhances visibility for safer driving.

The longevity of LEDs is another advantage, with lifespans often reaching 50,000 hours compared to just 1,000 hours for incandescent bulbs. This durability translates to fewer replacements and lower maintenance costs for manufacturers and vehicle owners alike.

5. Resistance to Moisture and Dust

Automotive indicator lights, especially those on the exterior of vehicles, face constant exposure to rain, mud, and dust. Choosing LEDs with high Ingress Protection (IP) ratings, such as IP67 or IP68, ensures they are sealed against water and debris. This protection prevents short circuits and maintains reliability in wet or dirty conditions, a common challenge for vehicles operating in diverse environments.

Benefits of Using LED Technology for Automotive Indicator Lights

LED technology has revolutionized automotive lighting, offering numerous advantages over older technologies. Here’s why LEDs are the preferred choice for indicator lights in terms of durability and reliability.

1. Superior Durability Against Physical Stress

Unlike traditional bulbs with fragile filaments, LEDs are solid-state devices with no moving parts. This makes them inherently more resistant to shocks and vibrations, key factors in automotive applications. Their rugged design means they are less likely to break or fail during high-impact events, such as driving over potholes or minor collisions.

2. Lower Heat Generation

LEDs produce significantly less heat than incandescent bulbs, reducing the risk of overheating and damage to surrounding components. This is particularly important in enclosed spaces like taillight assemblies, where heat buildup can degrade materials over time. The low heat output of LEDs also contributes to their extended lifespan and consistent performance.

3. Faster Response Time

LED car indicators illuminate almost instantly, with response times as low as 0.1 milliseconds compared to 200 milliseconds for incandescent bulbs. This rapid activation provides an earlier warning to other drivers, potentially reducing the risk of rear-end collisions by giving them more time to react.

How to Select the Right Indicator Lights for Your Automotive Project

With the variety of options available, narrowing down the best indicator lights for your automotive application can seem daunting. Follow these practical steps to make an informed decision focused on durability and reliability.

Step 1: Assess Environmental Conditions

Start by evaluating the operating environment of the vehicle. Will it face extreme temperatures, heavy vibrations, or frequent exposure to moisture? Match the LED specifications—such as temperature range, vibration resistance, and IP rating—to these conditions. For example, off-road vehicles may require higher vibration resistance, while electric vehicles in cold climates need extended temperature range LEDs.

Step 2: Verify Compliance with Standards

Ensure the indicator lights meet automotive industry standards like AEC-Q101 for LEDs or relevant regional regulations for brightness and color output. Compliance guarantees that the components have been rigorously tested for reliability and safety, reducing the risk of failures in the field.

Step 3: Evaluate Power Requirements

Check the voltage and current requirements of the LEDs to ensure compatibility with the vehicle’s electrical system. Most automotive indicator lights operate at 12V or 24V, but variations exist. Overloading or underpowering can lead to flickering or burnout, so confirm the specifications with the manufacturer’s datasheet.

Step 4: Prioritize Longevity and Maintenance

Opt for LED car indicators with long lifespans and minimal maintenance needs. While the upfront cost of high-quality LEDs may be higher, the reduced frequency of replacements and repairs offers significant savings over time. Look for products with warranties or documented test data on durability.

Common Challenges and Solutions with Automotive Indicator Lights

Even with the best components, challenges can arise in automotive lighting applications. Here are some common issues related to durability and reliability, along with solutions to address them.

Challenge 1: Flickering or Dimming

Flickering or dimming often results from voltage fluctuations or poor connections in the vehicle’s electrical system. To solve this, use LEDs with built-in voltage regulation or add external resistors to stabilize power delivery. Also, ensure secure wiring and connections to prevent intermittent contact.

Challenge 2: Color Fading Over Time

Some LEDs may experience color shifts or fading due to prolonged exposure to UV light or high temperatures. Selecting automotive grade LEDs with UV-resistant coatings and robust thermal management can mitigate this issue, maintaining consistent color output over the product’s lifespan.

Challenge 3: Compatibility Issues

Older vehicles or custom designs may not be fully compatible with modern LED indicators, leading to issues like hyper-flashing (rapid blinking). Installing load resistors or CANbus-compatible LEDs can resolve these problems, ensuring smooth integration with existing systems.

Future Trends in Automotive Indicator Lights

The automotive lighting industry is evolving rapidly, with new technologies enhancing durability and reliability. One trend is the adoption of smart LEDs with integrated control systems for adaptive brightness and dynamic signaling. These systems adjust light output based on ambient conditions, improving visibility and energy efficiency.

Another development is the use of advanced materials, such as ceramic substrates, in LED designs to improve heat dissipation and vibration resistance. As electric and autonomous vehicles become more prevalent, indicator lights will also need to integrate with complex sensor networks, requiring even higher reliability standards.

Conclusion: Building Reliable Automotive Systems with the Right Indicator Lights

Selecting indicator lights for automotive applications is a critical decision that impacts safety, performance, and cost. By focusing on durability and reliability through vibration resistant LEDs, automotive grade LEDs, and extended temperature range LEDs, engineers can design systems that withstand the toughest conditions. LED car indicators offer unmatched benefits, from energy efficiency to long lifespans, making them the ideal choice for modern vehicles.

At ALLPCB, we understand the importance of high-quality components in automotive projects. By carefully evaluating environmental factors, compliance standards, and technical specifications, you can ensure your indicator lights deliver consistent performance over time. Whether you’re working on passenger cars, commercial vehicles, or specialized machinery, the right automotive indicator lights are the foundation of a safe and reliable system.

ALLPCB

ALLPCB