Overview

As electric vehicles (EVs) become more widespread, the on-board charger (OBC) is increasingly important. The OBC not only supplies power to the vehicle but also manages battery charging to protect battery life and performance. Consequently, OBC performance directly affects the user experience of EVs.

With rapid development in the new-energy vehicle sector, trends such as intelligence, lightweighting, and increased integration are emerging. The OBC is a critical component for vehicle safety and stability, and its power density influences vehicle mass, driving range, and charging time.

SiC Benefits for OBCs

Silicon carbide (SiC), as a third-generation semiconductor, offers high-temperature tolerance, high-voltage capability, high switching frequency, and radiation resistance. Using SiC power devices can reduce power conversion energy loss in electric or hybrid vehicles by about 20%. In OBC products, SiC power devices play an important role in improving efficiency, power density, and mass density.

SiC devices' high-voltage capability makes them well suited for high-voltage OBC designs. They can tolerate higher voltages, enabling reductions in circuit board size and weight and improving system efficiency. Their fast switching speed and low losses enable faster charging and reduced charging time. Higher efficiency during charging reduces energy waste and lowers charging cost. SiC devices also exhibit excellent thermal stability, allowing reliable operation in high-temperature environments that vehicles may encounter.

Bidirectional OBC Functionality

A bidirectional on-board charger enables power flow in both directions between the vehicle and the grid. This capability allows the OBC to charge the vehicle from the grid and to export energy from the vehicle back to the grid or to local loads, increasing energy flexibility and overall efficiency.

Bidirectional OBCs can improve energy utilization and provide flexibility for EV users. For example, owners can sell electricity back to the grid during high-demand periods or use the vehicle as a backup power source for a home during outages. Bidirectional capability also supports grid stability and the integration of renewable energy sources.

OBC Operating Principles

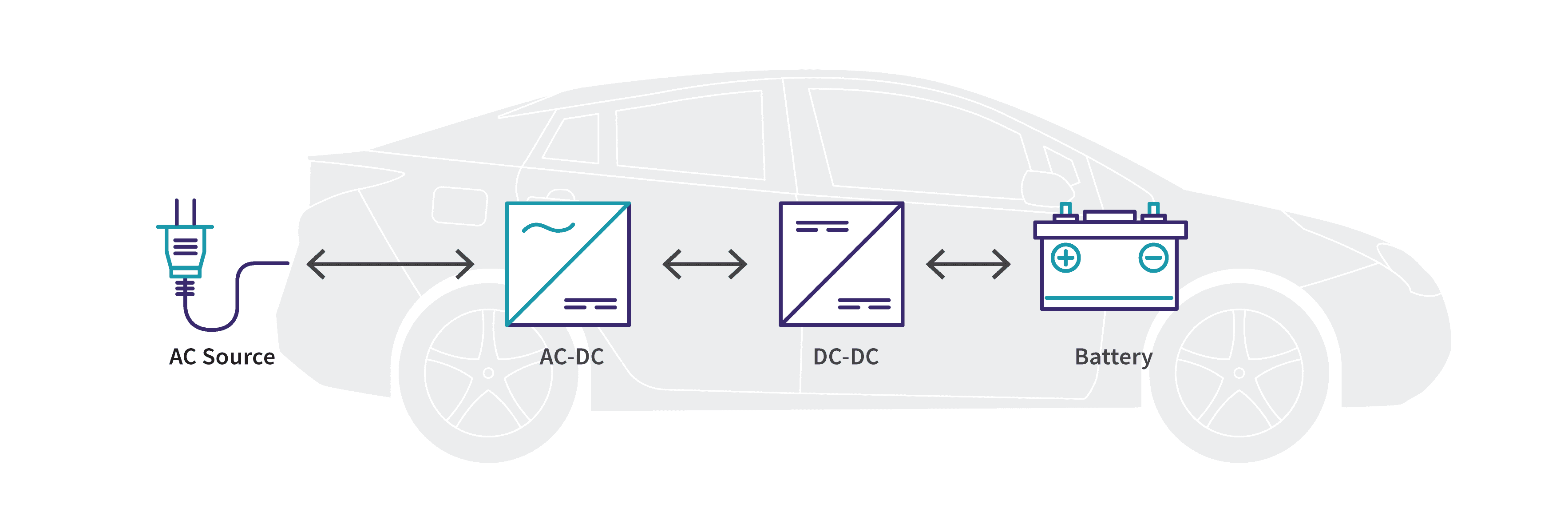

The bidirectional OBC performs two core functions: charging the vehicle from the grid (AC to DC conversion) and exporting stored energy back to the grid or other AC systems (DC to AC conversion).

Receiving AC: When the vehicle connects to an AC source, such as a home outlet or public charger, the OBC first receives the alternating current.

AC-DC conversion: The incoming AC is converted to DC by an AC-DC converter, typically including a rectifier, and the resulting DC is used to charge the battery.

DC-AC conversion: In reverse mode, the OBC draws DC from the vehicle battery and uses a DC-AC inverter to convert it into AC.

Feedback to the grid or local loads: The resulting AC can be fed back to the grid or used locally for household or facility loads, for example during grid peak periods or emergency power needs.

Challenges and Considerations

Despite the advantages of SiC devices in OBCs, challenges remain, including manufacturing processes, cost, safety, and reliability. Addressing these issues requires advanced manufacturing techniques, optimized production workflows, cost control, and rigorous safety and reliability testing.

Outlook

As the EV market expands, OBC performance and efficiency will become increasingly important. SiC devices are expected to see broader application in OBCs, especially in high-power and high-efficiency designs. Continued research and technology development will be essential to overcome current challenges and advance SiC adoption in OBCs, enabling more efficient and reliable charging solutions.

ALLPCB

ALLPCB