Overview

Underground utility tunnels carry power, communication, and water services. Electrical equipment in these enclosed, often humid and high-load environments is prone to partial discharge, which can lead to insulation degradation, equipment failure, or fire. An online partial discharge monitoring system for underground utility tunnels provides real-time sensing, analysis, and early warning to improve electrical safety in these spaces.

Technical core: multi-dimensional sensing and algorithm fusion

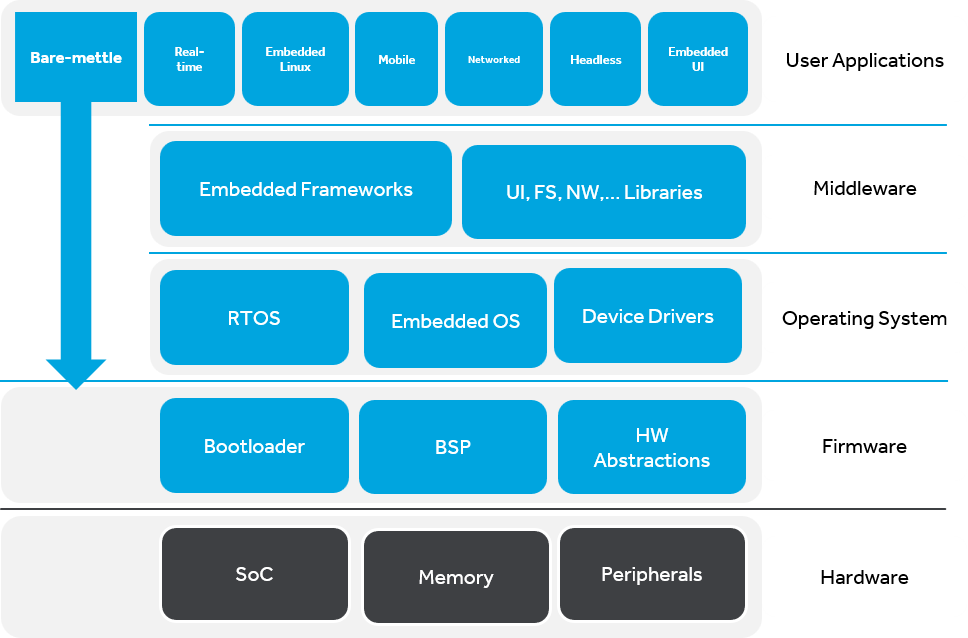

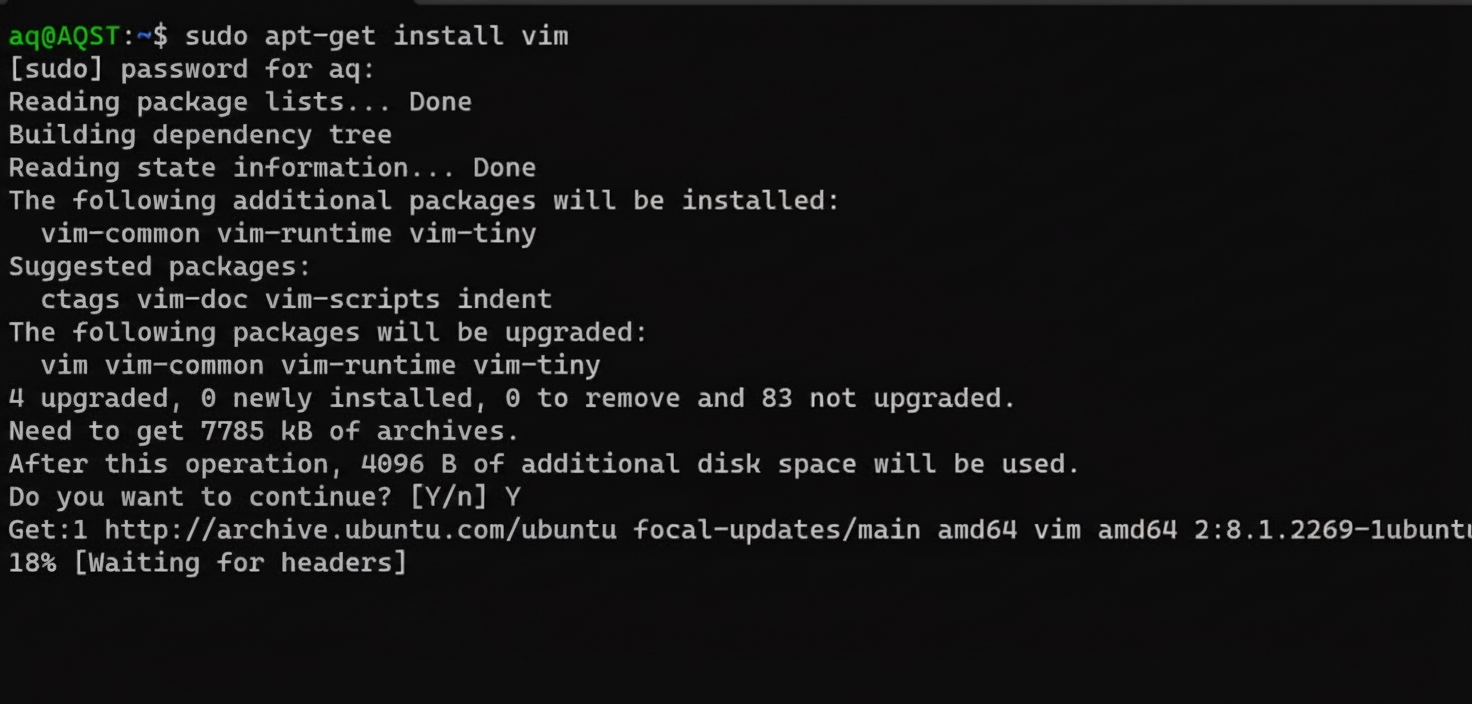

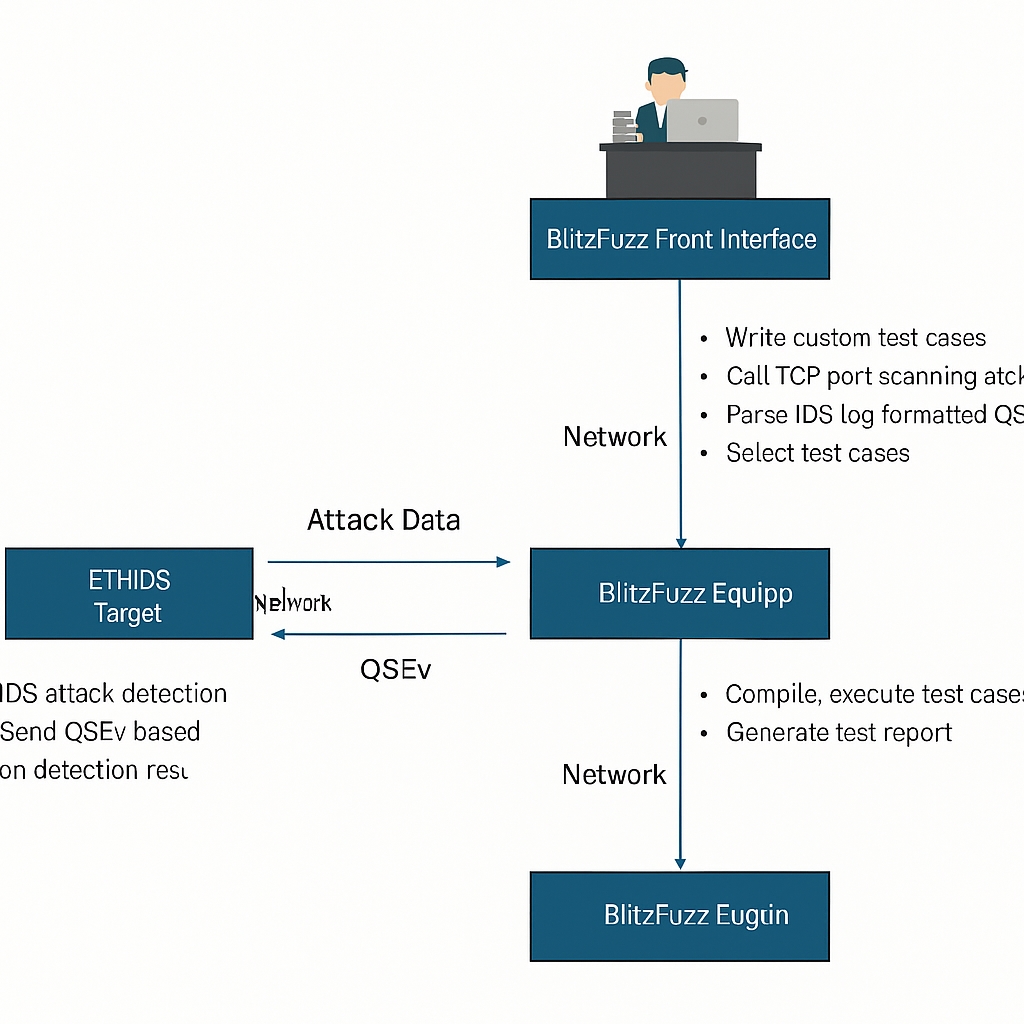

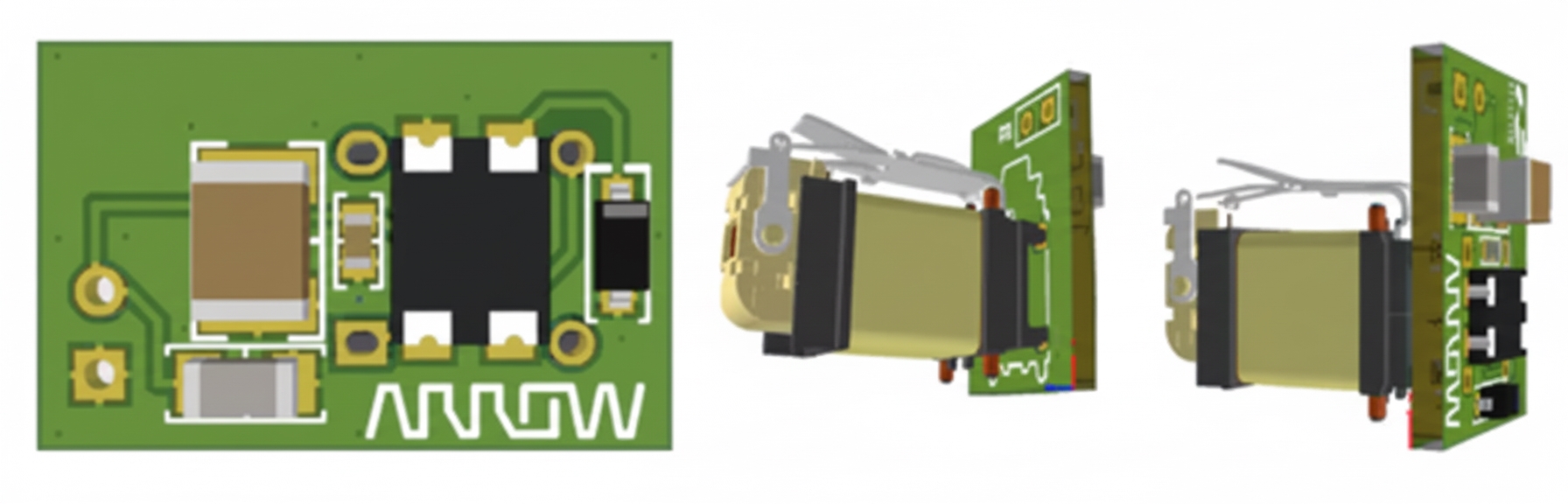

The system uses a "sensor array + edge computing + cloud analysis" architecture. Ultrasonic sensors capture mechanical vibration waves generated by partial discharge. UHF sensors detect electromagnetic pulse signals. High-frequency current sensors monitor impulse currents on grounding conductors. With non-intrusive installation, sensors can be deployed while equipment is energized. Adaptive filtering algorithms suppress environmental noise to ensure accurate extraction of partial discharge features under strong electromagnetic interference and high humidity. Edge computing units perform time-frequency analysis on raw data and extract feature parameters such as discharge amplitude, repetition rate, and phase distribution.

Operational value: from reactive repairs to proactive maintenance

Traditional manual inspections have long cycles, large blind spots, and slow response. An online monitoring system delivers continuous 24/7 monitoring and removes temporal and spatial constraints. When it detects typical defects such as corona discharge, surface discharge, or internal discharge, the system triggers multi-level alarms and synchronizes data to the maintenance platform. Combined with equipment health scoring models, it can warn of insulation aging trends in advance and support differentiated inspection schedules to avoid unplanned outages. In emergencies, the system can rapidly locate fault points, shorten repair time, and reduce the risk of secondary incidents.

Maintenance practice: standardized procedures for long-term stability

To ensure long-term, accurate operation, establish a standardized maintenance regime. Perform quarterly calibrations using a reference source to verify sensor accuracy. Conduct routine cleaning to prevent dust or oil from affecting sensitivity. Inspect connectors to ensure stable signal transmission. Use enclosures that meet appropriate protection ratings to maintain reliability in humid or corrosive environments. Maintain device health records that log maintenance history and fault cases to support data-driven maintenance decisions.

Future direction: integration and intelligent operation

With the convergence of the Internet of Things and artificial intelligence, systems are evolving toward an intelligent loop of sensing, analysis, decision, and action. Digital twin models can provide real-time mapping between physical and virtual systems. Integrating temperature measurement and gas monitoring can form comprehensive power-safety sensing terminals. Combined with 5G communication, remote real-time monitoring and automatic alarm delivery become feasible. These developments will shift maintenance from scheduled checks to condition-based strategies, extend equipment life, and reduce life-cycle costs.

Conclusion

In underground utility tunnels, online partial discharge monitoring moves the safety boundary forward to detect hazards at their inception. As detection accuracy and automation improve, these systems will strengthen the safe operation of underground infrastructure and support resilient urban services.

ALLPCB

ALLPCB