Summary: Gas Sensor Selection Guide

When a kitchen gas alarm sounds, a formaldehyde meter reports high values in a new home, or a mine monitor shows a red warning, a gas sensor is detecting invisible, colorless gas molecules in the air and converting their concentration into an electrical signal for safety monitoring. Different gas sensor types use distinct detection methods and are suited to different applications. This article reviews the main gas sensing technologies and their typical uses.

Gas Sensor Technologies: Principle Determines Strengths

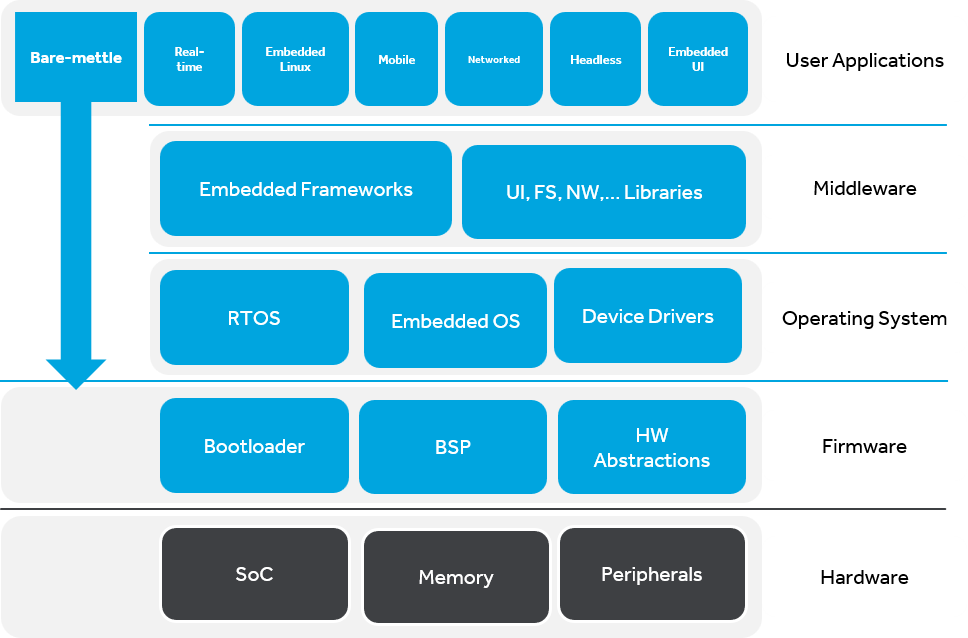

Gas sensors convert gas concentration into an electrical signal. The core differences among sensor technology routes lie in how the gas is sensed. Main mainstream gas sensing technologies include catalytic combustion, electrochemical, semiconductor, and infrared absorption. Advanced types include laser-based, photoionization detection (PID), and photoacoustic spectroscopy (PAS). Users should select the appropriate technology according to application requirements.

1. Catalytic Combustion: The Combustible-Gas Sentinel

A catalytic combustion sensor uses a detector element coated with a catalyst (typically a platinum wire). When air containing combustible gas (such as methane, propane, hydrogen) contacts the detector, the gas undergoes flameless combustion on the catalyst surface. The released heat raises the platinum wire temperature, increasing its electrical resistance. The sensor measures resistance change and converts it to gas concentration: more intense combustion indicates higher concentration and larger resistance change. Catalytic combustion sensors require an oxygen environment to operate. They respond broadly to combustible gases but cannot distinguish between different combustible species.

2. Electrochemical: Precise Chemical Analyst

Electrochemical sensors contain an electrolyte and electrodes. When target gases (for example carbon monoxide, sulfur dioxide, formaldehyde, oxygen) pass through a gas-permeable membrane and reach the electrolyte, oxidation or reduction reactions occur at the working electrode. These reactions produce a small electrical current proportional to the gas concentration, so the sensor measures current to determine concentration.

Different target gases require specific electrolyte and electrode materials, giving electrochemical sensors high specificity. They are highly sensitive to low concentrations and well suited for detecting toxic or hazardous gases.

3. Semiconductor: Fast Resistance-Change Scout

Semiconductor sensors use a metal oxide semiconductor as the core element. At elevated temperature the semiconductor surface forms an oxygen-containing layer with relatively stable resistance. When target gases (such as alcohol, ammonia, hydrogen sulfide) contact the surface, they react with the oxide layer: reducing gases remove oxygen from the layer and decrease resistance, while oxidizing gases increase oxygen content and raise resistance. The sensor detects abrupt resistance changes to indicate presence and concentration.

Semiconductor sensors offer fast response—typically within seconds—low cost, and small size. However, they have lower accuracy and stability and are susceptible to environmental factors like temperature and humidity.

4. Infrared Absorption: Spectral Identifier

Different gases have unique infrared absorption "fingerprints": specific infrared wavelengths are absorbed by corresponding gas molecules, and absorption strength is proportional to concentration. Infrared absorption sensors emit chosen infrared wavelengths through a detection cell containing the target gas and measure transmission intensity. The attenuation of transmitted infrared light is used to calculate gas concentration precisely.

Infrared absorption provides strong specificity and accurate discrimination among gases, and it is largely unaffected by oxygen or humidity. It offers high stability and precision but involves more complex structure and higher cost, making it suitable for applications requiring high accuracy.

5. Photoionization Detection (PID): UV Ionization Inspector

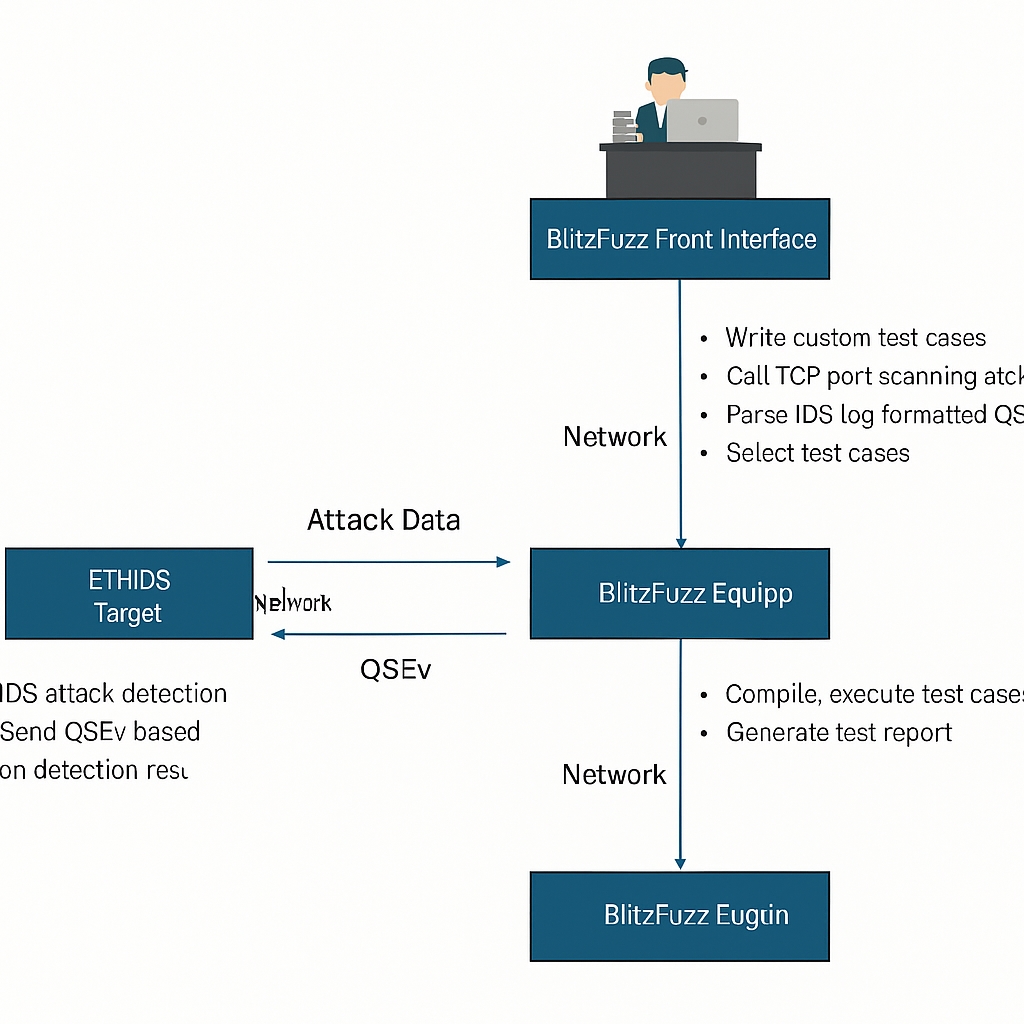

PID uses ultraviolet (UV) light to ionize gas molecules in an ionization chamber, producing a detectable current signal. Typical PID structure includes a UV lamp, ionization chamber, electrode system, sampling system, and signal processing circuit. PID is suitable for detecting volatile compounds and vapors with ionization energy below the UV photon energy, mainly volatile organic compounds (VOCs), ammonia, hydrogen sulfide, and similar species.

Service Life and Applications: Sensor Type Determines Lifetime and Field

Sensor lifetime varies widely depending on whether the core element undergoes wear and how quickly. Choosing the right sensing technology for an application requires balancing accuracy, cost, and environmental suitability.

| Sensor Type | Typical Service Life | Core Advantages | Main Limitations | Typical Applications |

|---|---|---|---|---|

| Catalytic Combustion | 0.5–3 years | Wide detection range, stable detection | Requires oxygen, low selectivity, component wear | Mine detection, industrial combustible gas leak alarms, domestic gas detectors |

| Electrochemical | 1–3 years (some oxygen sensors up to 5 years) | Precise detection of toxic gases, high sensitivity | Electrolyte depletion, affected by temperature and humidity | Carbon monoxide detection, formaldehyde detection, automotive exhaust monitoring, industrial toxic gas monitoring |

| Semiconductor | 3–5 years | Fast response, low cost, small size | Lower accuracy, poorer stability, prone to interference | Alcohol testing, ammonia detection in agriculture, food freshness, odor/air quality detection |

| Infrared Absorption | 5–10 years | High precision, strong stability, gas discrimination | High cost, professional maintenance | Industrial process gas analysis, environmental monitoring stations, medical gas monitoring, natural gas analysis |

Sensor Selection: Choosing the Right "Detective"

Below are selection suggestions for common scenarios based on sensor characteristics.

Home and Residential

Balance cost and reliability. Household concerns are primarily combustible gas leaks and carbon monoxide poisoning. For combustible gas leaks (mainly methane), catalytic combustion detectors are a common choice due to stable detection and relatively long service life at reasonable cost. For carbon monoxide from gas water heaters or boilers, electrochemical carbon monoxide detectors provide accurate low-concentration detection to prevent poisoning.

For formaldehyde from new renovations, electrochemical formaldehyde detectors offer sufficient accuracy for home use. For quick checks of bathroom odors (mainly ammonia), refrigerator food freshness, or general indoor air quality for higher-end living, semiconductor-based sensors can offer better cost performance.

Industrial Production

Prioritize accuracy and durability. In underground spaces such as mines, monitoring methane concentration is critical; catalytic combustion sensors can operate reliably in complex underground environments and provide timely warnings for combustible gas leaks. In chemical plants where toxic gases like sulfur dioxide or chlorine may be present, electrochemical sensors' high sensitivity and specificity are valuable for personnel protection.

For precise concentration monitoring in pipeline transport or oil and gas extraction, or when process control requires accurate gas composition data, infrared absorption sensors provide stable, high-precision long-term measurements to protect production efficiency, product quality, and personnel safety.

Specialized Professional Scenarios

Use dedicated technologies tailored to the application. Breath alcohol testers for roadside testing typically use semiconductor sensors that deliver rapid results within seconds. In surgical anesthesia, accurate real-time monitoring of anesthetic gas concentrations favors infrared sensors due to their precision. Environmental monitoring stations rely on infrared sensors for long-term monitoring of gases such as carbon dioxide and methane because of their long service life and stability, providing reliable data for research. For utilities monitoring sulfur hexafluoride (SF6) in power substations, infrared gas sensors are commonly used due to high precision, interference resistance, and long life.

PID technology, with its sensitivity to low-volatility gases and vapors, plays an important role in industrial safety, chemical leak detection, fuel vapor monitoring at refueling sites, and emergency response at hazardous chemical incidents.

Conclusion

From homes to factories, restaurants to hospitals, and environmental stations, different gas sensing technologies protect safety and health using their respective strengths. Sensor development continues toward smaller size, lower cost, and higher accuracy, and sensors will play an increasing role across more application scenarios as essential unseen safety devices.

ALLPCB

ALLPCB