When it comes to designing printed circuit boards (PCBs) for MRI machines, component selection is critical to ensure reliability and longevity. MRI systems operate in demanding environments with strict requirements for precision, safety, and durability. Choosing the right components—such as medical grade components, high-reliability components, and extended temperature range components—can make the difference between a system that performs flawlessly for years and one that fails prematurely. In this blog, we’ll dive deep into the essentials of MRI PCB component selection, exploring how to prioritize quality, manage component obsolescence, and meet the unique challenges of medical imaging equipment.

Why Component Selection Matters for MRI Machine PCBs

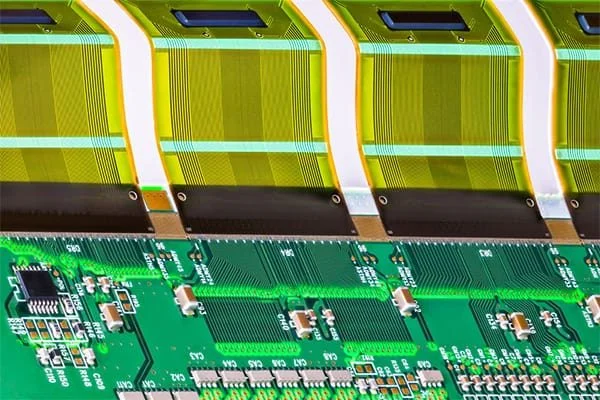

MRI machines are complex medical devices that rely on PCBs to control critical functions like signal processing, power management, and data acquisition. These systems must operate with exceptional accuracy to produce clear images while ensuring patient safety. A single faulty component can lead to system downtime, costly repairs, or even compromised diagnostics. That’s why MRI PCB component selection focuses on reliability, compatibility with harsh environments, and long-term availability.

Components in MRI systems face unique challenges, including high magnetic fields, temperature fluctuations, and the need for low noise in signal processing. By selecting medical grade components and high-reliability components, designers can build PCBs that withstand these conditions and deliver consistent performance over time.

Key Factors in MRI PCB Component Selection

Selecting components for MRI machine PCBs requires careful consideration of several factors. Let’s break down the most important aspects to ensure reliability and longevity in these critical applications.

1. Prioritizing Medical Grade Components

Medical grade components are specifically designed to meet the stringent standards of the healthcare industry. These components undergo rigorous testing to ensure they can operate safely and reliably in medical devices. For MRI machines, using medical grade components is non-negotiable due to the potential risks to patients and operators if a system fails.

These components are often certified to standards like ISO 13485, which governs quality management for medical devices. They are also designed to minimize electromagnetic interference (EMI), a critical factor in MRI systems where even minor noise can distort imaging results. For example, capacitors and resistors used in signal filtering circuits should have tight tolerance levels (e.g., ±1% for resistors) to maintain signal integrity.

2. Choosing High-Reliability Components

High-reliability components are engineered to perform consistently under stress and over extended periods. In MRI machines, where downtime can delay critical diagnoses, reliability is paramount. These components are often tested for failure rates as low as 0.1% over 10,000 hours of operation, ensuring they can handle the demands of continuous use.

For instance, power management ICs in an MRI PCB must maintain stable voltage levels (e.g., 3.3V or 5V) even during power surges or fluctuations. Similarly, connectors and switches should be rated for thousands of cycles to prevent wear-out failures. Opting for components with military or aerospace-grade specifications can provide an extra layer of assurance for reliability.

3. Considering Extended Temperature Range Components

MRI machines often operate in environments with significant temperature variations. The powerful magnets in these systems are cooled by liquid helium to temperatures near -269°C (-452°F), while other parts of the system may reach elevated temperatures due to electrical loads. Extended temperature range components are essential to ensure functionality across these extremes.

Components rated for industrial or automotive temperature ranges (e.g., -40°C to 85°C or even -55°C to 125°C) are often suitable for MRI applications. For example, microcontrollers used in control circuits should maintain performance at both ends of this spectrum without drift in clock speed or processing errors. Similarly, passive components like inductors should have stable inductance values (e.g., 10 μH ±10%) regardless of temperature shifts.

4. Managing Component Obsolescence

Component obsolescence management is a significant concern for MRI machine manufacturers. These systems have long lifecycles—often 10 to 20 years—while electronic components may become obsolete within a few years due to rapid technological advancements. A discontinued component can halt production or force costly redesigns.

To mitigate this risk, designers should select components with long-term availability commitments from suppliers. Many manufacturers offer lifecycle status information, indicating whether a part is active, nearing end-of-life, or obsolete. Additionally, choosing components with multiple sourcing options can reduce dependency on a single supplier. For critical parts like analog-to-digital converters (ADCs) used in MRI signal processing, it’s wise to stockpile inventory or plan for drop-in replacements with similar specs (e.g., 16-bit resolution, 100 kSPS sampling rate).

Technical Challenges in MRI PCB Component Selection

Beyond the general factors of reliability and availability, MRI machines present specific technical challenges that influence component selection. Understanding these challenges helps designers make informed choices for optimal performance.

Handling High Magnetic Fields

MRI systems generate magnetic fields as strong as 1.5 to 3 Tesla, or even higher in advanced systems. These fields can interfere with electronic components, causing malfunctions or signal distortion. Non-magnetic components, such as ceramic capacitors and non-ferrous connectors, are essential to prevent unwanted interactions with the magnetic field.

For example, inductors or transformers with ferromagnetic cores should be avoided in favor of air-core or ceramic-core alternatives. Additionally, shielding techniques, such as using mu-metal enclosures around sensitive circuits, can protect components from magnetic interference.

Minimizing Noise and EMI

Signal clarity is critical in MRI machines, where even small amounts of noise can degrade image quality. Components like operational amplifiers (op-amps) and ADCs must have low noise figures (e.g., less than 5 nV/√Hz for op-amps) to ensure clean signal amplification and conversion. Filters and decoupling capacitors should also be chosen for their ability to suppress high-frequency noise, often in the range of 1 MHz to 100 MHz.

Proper PCB layout goes hand-in-hand with component selection to minimize EMI. Placing bypass capacitors close to power pins of ICs and using ground planes can reduce noise coupling. Components with built-in EMI suppression features, such as shielded inductors, are also beneficial.

Ensuring Power Efficiency

MRI systems consume significant power, especially for magnet operation and gradient coils. Power management components, such as voltage regulators and DC-DC converters, must be highly efficient to minimize heat generation and energy loss. For instance, a switching regulator with 95% efficiency can reduce thermal stress on nearby components compared to a linear regulator with only 60% efficiency.

Heat dissipation is another concern, as excessive temperatures can degrade component performance. Selecting components with low thermal resistance and high power ratings ensures they can handle the load without overheating.

Best Practices for MRI PCB Component Selection

To achieve the best results in MRI PCB design, follow these practical tips for component selection. These practices can help ensure reliability, longevity, and compliance with medical standards.

Work with Trusted Suppliers

Partner with component suppliers who specialize in medical and high-reliability applications. These suppliers often provide detailed datasheets, application notes, and support for selecting components that meet industry standards. They can also offer insights into long-term availability and potential substitutes for obsolete parts.

Test Components Under Real-World Conditions

Before finalizing component choices, test them in conditions that mimic the MRI environment. This includes exposing components to high magnetic fields, temperature extremes, and continuous operation cycles. For example, stress-testing a microcontroller at 85°C for 1,000 hours can reveal potential failure modes before they occur in the field.

Document and Standardize Selection Criteria

Create a standardized checklist for component selection that includes parameters like temperature range, reliability ratings, and compliance with medical standards. Documenting these criteria ensures consistency across projects and simplifies future redesigns or upgrades.

Plan for Scalability and Upgrades

Choose components that allow for scalability, such as microcontrollers with extra processing headroom or connectors with additional pins for future expansion. This forward-thinking approach can extend the lifespan of an MRI system by accommodating software updates or hardware modifications without requiring a complete PCB overhaul.

The Role of Quality PCB Manufacturing in Component Performance

Even the best components can underperform if the PCB manufacturing process is substandard. High-quality assembly and fabrication are essential to ensure that components operate as intended. This includes precise soldering to prevent cold joints, accurate placement to avoid misalignment, and thorough testing to catch defects early.

At ALLPCB, we understand the importance of precision in medical device manufacturing. Our advanced production capabilities and strict quality control measures ensure that every PCB meets the demanding requirements of MRI systems. By pairing high-reliability components with top-tier manufacturing, we help designers achieve optimal performance and durability.

Conclusion: Building MRI PCBs for the Future

Component selection for MRI machine PCBs is a balancing act of reliability, performance, and long-term availability. By focusing on medical grade components, high-reliability components, and extended temperature range components, designers can create systems that deliver accurate imaging and withstand the rigors of medical environments. Effective component obsolescence management further ensures that MRI systems remain operational for years without costly redesigns.

The process requires attention to detail, from minimizing EMI to handling high magnetic fields and ensuring power efficiency. By following best practices and partnering with experienced manufacturers, engineers can build MRI PCBs that prioritize patient safety and diagnostic precision. At ALLPCB, we’re committed to supporting this journey with high-quality PCB solutions tailored to the needs of medical technology.

Whether you’re designing a new MRI system or upgrading an existing one, thoughtful MRI PCB component selection is the foundation of success. With the right components and manufacturing support, you can achieve reliability and longevity that stand the test of time.

ALLPCB

ALLPCB