Overview

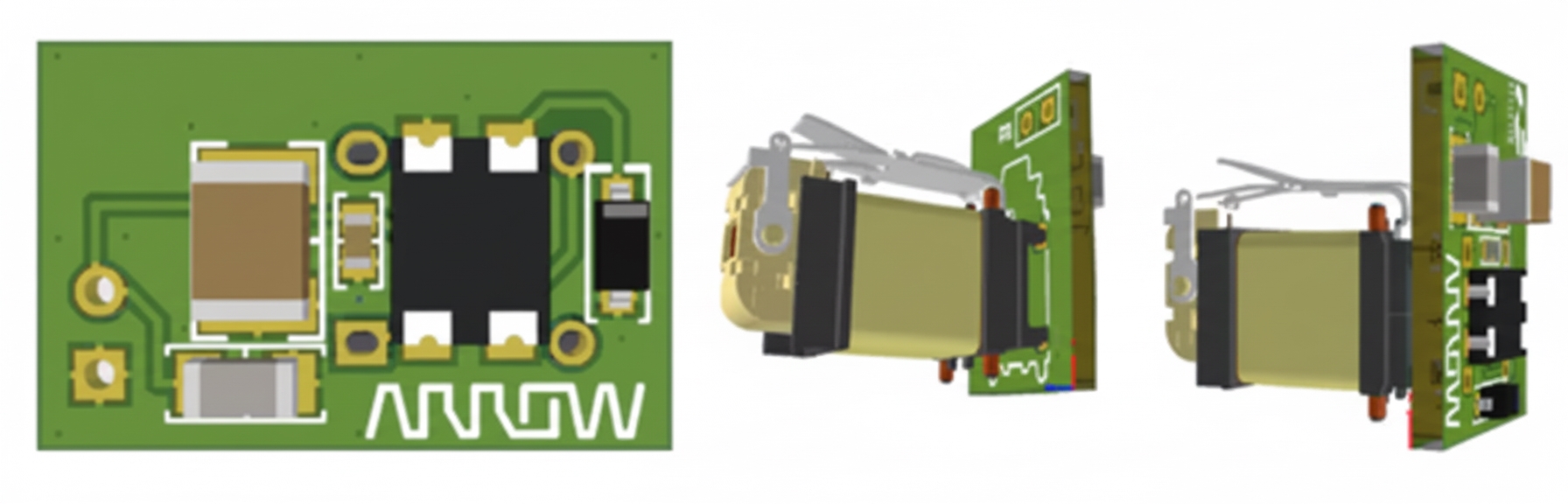

At the 27th China International Gas and Heating Technology and Equipment Exhibition, a vendor demonstrated an ultrasonic flow measurement series designed for the gas and heating sectors. The series includes sensors with 200 kHz and 500 kHz emission frequencies and related product solutions.

With global energy metering standards becoming more stringent, ultrasonic gas flow sensors, which have no moving parts, long operational life, and the potential for high accuracy, are increasingly used for metering natural gas, town gas, hydrogen, and other gases. Within this technical evolution, the choice of operating frequency is a primary factor that defines sensor performance limits and suitable application scenarios.

Frequency Defines Application Boundaries

Selecting the appropriate emission frequency depends on the core requirements of the target application.

When to Choose a 200 kHz Sensor

When an application requires coverage of a wide flow range and the field conditions may include minor contaminants, 200 kHz sensors offer better penetration and a wide dynamic range, making them a common choice in industrial metering. In cost-sensitive projects that still require reliable measurement, 200 kHz provides a balance between performance and cost.

200 kHz: Robust Choice for Wide-Range Industrial Metering

200 kHz ultrasonic gas flow sensors represent a compromise between detection depth and signal stability. Their relatively longer wavelength experiences less attenuation in gas, enabling effective penetration of the flow field and a more robust response to changes in flow velocity.

Typical Applications

- Gas flow monitoring in city distribution pressure-reduction stations

- Full-range flow metering for residential and industrial gas meters

- Gas supply control for industrial burners

Wide Dynamic Range and Adaptability

200 kHz transmit frequency can maintain stable signal output across both low and high flow rates. Its wide measurement range makes it suitable for sites with large flow fluctuations and for continuous recording of domestic gas usage, reducing under-registration at low flow and saturation at high flow.

Penetration and Interference Resistance

200 kHz sensors have better penetration through small amounts of condensate, dust, and other contaminants inside the pipe. Their signals are less affected by complex flow disturbances, supporting reliable long-term metering under non-ideal conditions.

System Integration and Cost Considerations

Ultrasonic gas flow measurement at the 200 kHz band is mature, and the associated circuit design is relatively straightforward. This simplifies integration with existing ultrasonic gas meter mainboards and supports cost-effective sensing modules for meter manufacturers.

When to Choose a 500 kHz Sensor

For applications that require detection of very small flows, very high safety standards, or fast dynamic response, 500 kHz sensors provide higher sensitivity and finer timing resolution. In safety alert systems, precision gas metering, and high-efficiency equipment control, 500 kHz can provide measurement capabilities that are difficult to achieve with lower frequencies.

500 kHz: Sensitive Microflow Detection and Dynamic Response

The higher frequency of 500 kHz yields a shorter wavelength and improved timing resolution, which enhances sensitivity to small flow variations and fine details in the flow field.

Typical Applications

- Precision metering of high-purity or specialty gases in laboratory environments

- Gas micro-leak detection and safety early-warning systems

- Precise energy management for premium gas appliances

Microflow High-Precision Detection

500 kHz sensors can detect extremely low gas velocities, such as minute leakage flows that occur after appliance shutdown. This capability supports early safety warnings and higher levels of usage safety.

High Dynamic Response and Instantaneous Measurement

Very short detection cycles enable rapid capture of instantaneous flow changes, providing accurate data for real-time control of gas equipment, such as high-efficiency boilers, and supporting energy efficiency optimization.

Improved Initial Measurement Accuracy

At the start of the measurement range, 500 kHz sensors can exhibit high linearity and accuracy, reducing the large relative errors often seen at the low end of traditional instruments and supporting precise metering across the device lifecycle.

ALLPCB

ALLPCB