China silicon carbide (SiC) substrate prices fell rapidly in 2024, with declines more pronounced than in other regions. This is mainly due to intense competition among suppliers in the Chinese market, which has driven down prices that had been stable for years.

In the global market, prices for mainstream 6-inch SiC substrates quoted by international suppliers remain in the $750–800 range. By comparison, Chinese manufacturers previously priced about 5% lower, but the gap has recently widened to around 30%.

Part 1

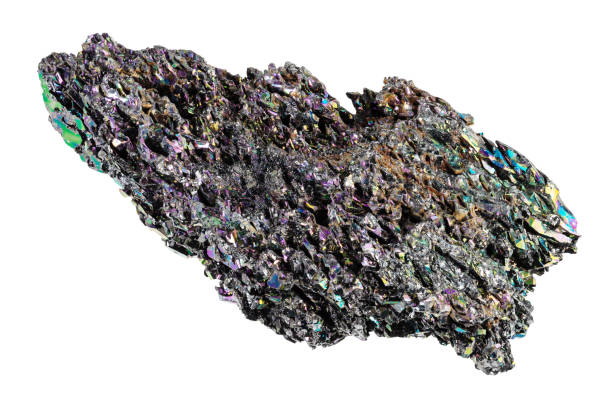

What is an SiC substrate

Silicon carbide single-crystal substrates (SiC substrates) are wide-bandgap semiconductor crystals. They offer advantages such as high-voltage tolerance, high-temperature operation, high-frequency performance, and low loss, and serve as the foundational material for fabricating high-power power electronic devices and microwave RF devices.

SiC single crystals are composed of silicon and carbon in a 1:1 stoichiometric ratio and have hardness second only to diamond. The crystal structure consists of Si-C tetrahedra, with silicon and carbon atoms each fourfold coordinated, forming stacking in Si-C bilayer directions. SiC has multiple polytypes, among which the 4H polytype is the most widely used in the semiconductor field.

Major methods for preparing SiC substrates include physical vapor transport (PVT), high-temperature chemical vapor deposition (HTCVD), and liquid-phase methods. The PVT method is mature and suitable for industrial mass production. It controls SiC crystal size and polytype by placing SiC seed crystals and SiC source powder at specific positions within a high-temperature, low-pressure sealed environment.

During SiC crystal growth using the PVT method, growth primarily follows a step-flow mechanism. In this mode, silicon and carbon atoms bond and grow at steps, causing the steps to advance in a parallel manner, which helps obtain a single polytype. Adjusting process parameters to control surface step structure and suppress polytypic defects is key to obtaining high-quality SiC crystals.

Producing high-quality SiC substrates requires, beyond crystal growth, subsequent processes such as cutting, grinding, beveling, polishing, cleaning, and inspection. Because SiC single crystals are hard and brittle, processing demands high technical capability. The high technical barriers of SiC substrate manufacturing make it a core link in the value chain.

The manufacturing flow for SiC devices is similar to silicon-based devices and includes substrate preparation, epitaxial growth, wafer fabrication, and packaging and testing. The value concentration of SiC devices is skewed: substrate and epitaxy together account for a large portion of cost. According to CASA data, these two stages combined represent about 70% of cost. Substrate manufacturing has the highest technical barrier and accounts for 47% of front-end cost, making it the most critical stage of the production process. As SiC power devices improve efficiency in applications such as electric vehicles and photovoltaic energy storage, demand continues to increase.

According to Yole, the global SiC power device market is projected to reach $4.9 billion by 2026, with a compound annual growth rate of about 35%. In the global SiC power device market by 2022 revenue, STMicroelectronics held about 37% market share, followed by Infineon and Wolfspeed with approximately 18% and 16% respectively.

Yole also forecasts that the global market for semi-insulating SiC RF devices will reach about $2.2 billion by 2026. With higher 5G penetration and the deployment of Massive MIMO, demand for GaN-on-SiC RF devices is expected to grow, with an estimated CAGR of about 16% through 2026.

Part 2

Substrate price war likely

Industry sources indicate that orders from China's electric vehicle manufacturers and international semiconductor IDMs no longer fully absorb the production capacity of SiC suppliers in China. Some Chinese companies plan to increase procurement from local supply chains, but several automakers may not raise domestic sourcing significantly for safety and reliability reasons, so self-sufficiency has not reached expected levels.

International semiconductor IDMs such as STMicroelectronics, Infineon, Onsemi, and ROHM continue to play an important role in the Chinese market for SiC components. Foreign car brands and joint ventures in China also mainly rely on these suppliers for SiC procurement.

With expansion of SiC production capacity in China, leading suppliers have cut prices by nearly 30% in recent months. As additional capacity comes online, prices are likely to continue declining.

Capacity deployment is advancing faster than technological progress. If demand is substantially lower than capacity, a price war in the sector is likely to begin.

Summary

Adoption of 800V systems appears increasingly likely, and prices for domestically produced SiC are expected to fall rapidly.

ALLPCB

ALLPCB