In the world of PCB design and manufacturing, data transfer formats play a critical role in ensuring accuracy and efficiency. For decades, the Gerber format has been the industry standard for conveying design data to manufacturers. However, as PCB designs grow more complex, the limitations of Gerber have become apparent. Enter IPC-2581, an advanced PCB data format that offers a single-file solution for transferring intricate design data. If you're wondering about IPC-2581 vs Gerber, or how this new standard improves complex PCB design data transfer, you're in the right place. In this post, we'll explore why replacing Gerber with IPC-2581 could be the future of PCB manufacturing and how it streamlines the process with a single file PCB transfer.

Let’s dive into the details of this advanced PCB data format and uncover how it addresses the challenges of modern PCB designs, saves time, and reduces errors.

Understanding the Basics: Gerber Format and Its Limitations

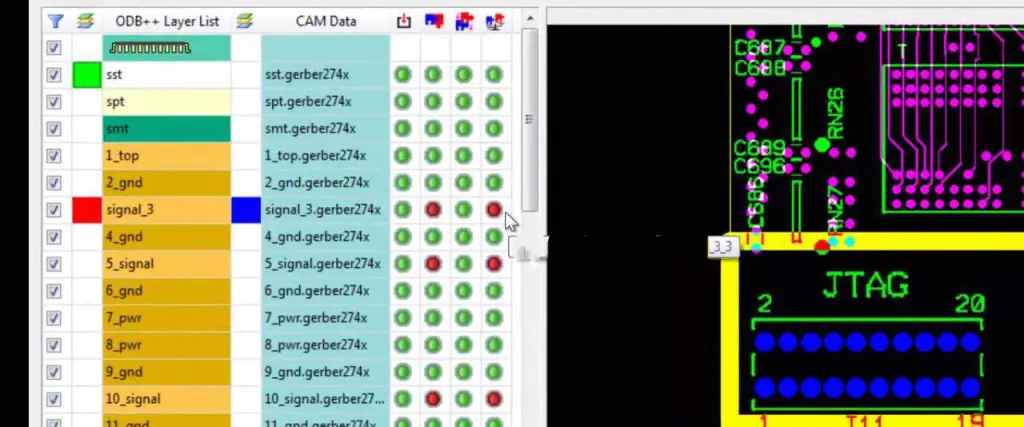

The Gerber format, introduced in the 1980s, has long been the go-to standard for PCB manufacturing data. It consists of a set of files that describe the physical layout of a PCB, including copper layers, solder masks, and drill holes. Each layer or aspect of the design is stored as a separate file, often accompanied by additional documents like netlists and bills of materials (BOM) to provide a complete picture.

While Gerber has served the industry well, it struggles to keep up with the demands of today’s intricate designs. For instance, a complex PCB with 16 layers might require over 20 separate Gerber files, plus additional files for drill data and assembly instructions. This fragmented approach can lead to errors, such as mismatched files or missing information, especially when designs include high-speed signals with strict impedance requirements (e.g., 50 ohms for USB 3.0 signals). Furthermore, Gerber lacks built-in intelligence, meaning it cannot convey critical metadata like stack-up details or material specifications directly within the files.

What Is IPC-2581? The Future of PCB Data Transfer

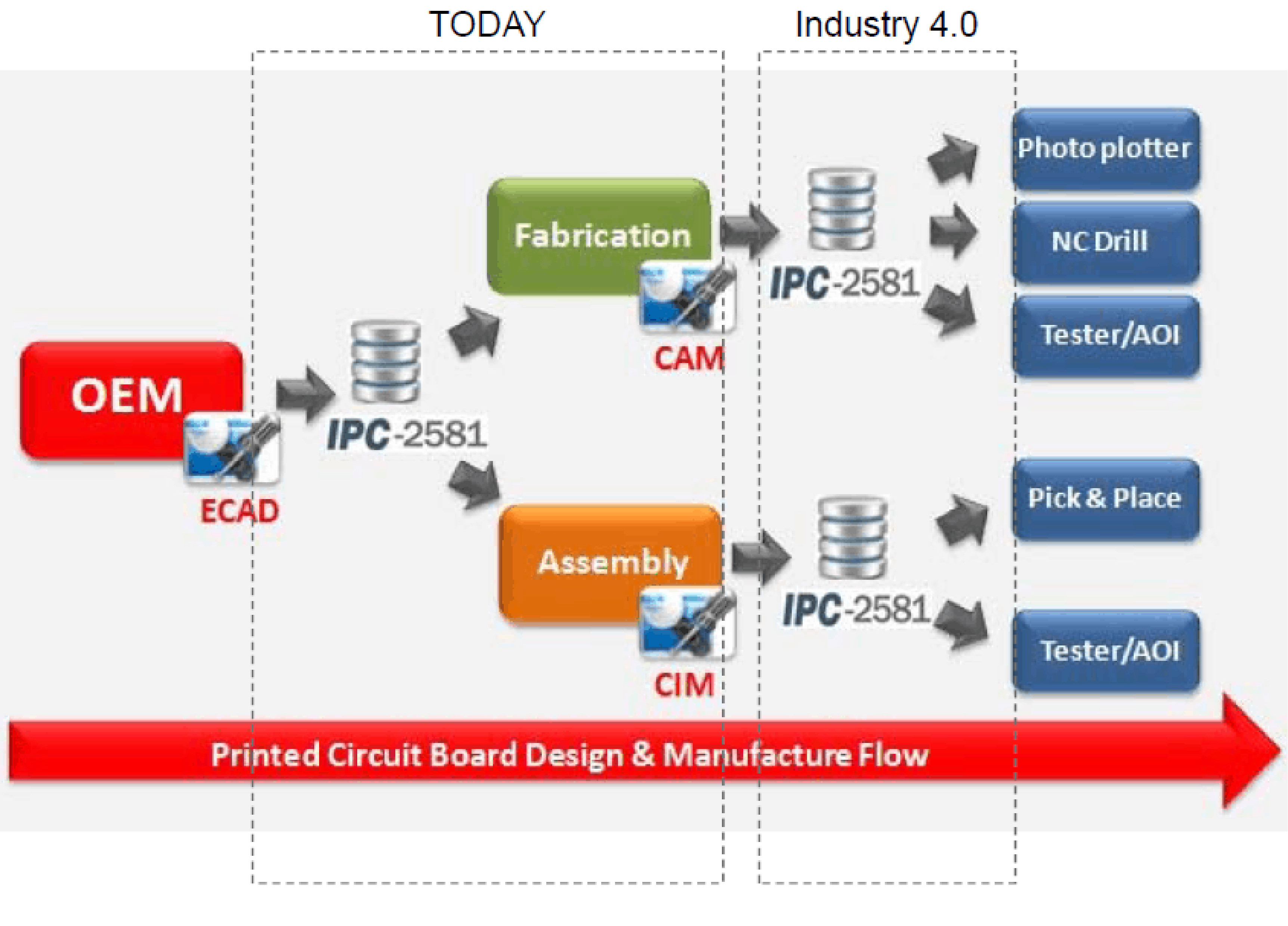

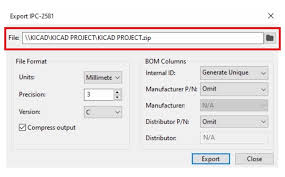

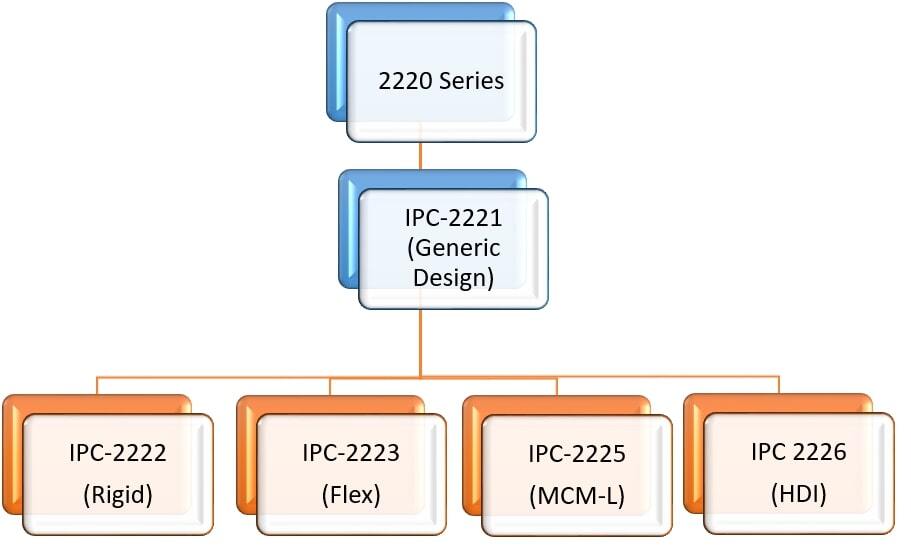

IPC-2581 is a modern, intelligent standard developed by the Institute of Printed Circuits (IPC) to address the shortcomings of older formats like Gerber. Unlike Gerber’s multi-file structure, IPC-2581 consolidates all design data into a single file PCB transfer package. This includes everything from copper layers and drill data to netlists, BOM, and even assembly instructions.

What sets IPC-2581 apart as an advanced PCB data format is its ability to embed metadata and design intent. For example, it can specify dielectric materials for controlled impedance (e.g., FR-4 with a dielectric constant of 4.2) or define test points for high-frequency signals operating at 5 GHz. This level of detail reduces ambiguity during manufacturing, ensuring that fabricators and assemblers have all the information they need in one place.

Since its introduction, IPC-2581 has gained traction as a solution for complex PCB design data transfer. It supports bidirectional communication between designers and manufacturers, allowing for feedback loops that can catch potential issues before production begins.

IPC-2581 vs Gerber: A Side-by-Side Comparison

Let’s break down the key differences between IPC-2581 and Gerber to understand why many engineers are considering replacing Gerber with IPC-2581.

- File Structure: Gerber requires multiple files for each layer and aspect of the design, often leading to a cumbersome set of 20-30 files for a single project. IPC-2581, on the other hand, uses a single file PCB transfer approach, bundling everything into one XML-based file.

- Intelligence and Metadata: Gerber files are essentially 2D images with no embedded intelligence, lacking information about design intent or material specs. IPC-2581 includes rich metadata, such as stack-up details and impedance requirements (e.g., 100 ohms differential pairs for Ethernet).

- Error Prevention: With Gerber, mismatched or missing files can cause manufacturing delays or defects. IPC-2581 minimizes these risks by consolidating data and enabling validation checks.

- Compatibility with Modern Tools: Most contemporary PCB design software supports IPC-2581 output, making it easier to adopt this format for complex PCB design data transfer.

How IPC-2581 Streamlines Complex PCB Designs

Modern PCB designs often involve high-density interconnects (HDI), fine-pitch components, and strict signal integrity requirements. These complexities demand a robust data transfer format, and IPC-2581 delivers on multiple fronts.

1. Simplified Data Management with Single File Transfer

Managing dozens of Gerber files for a multi-layer PCB is time-consuming and error-prone. With IPC-2581, all data is packaged into a single file, reducing the risk of lost or mismatched information. For instance, a 12-layer board with HDI features (e.g., 0.1 mm vias) can be fully described in one IPC-2581 file, including drill tolerances and layer stack-up details.

2. Enhanced Accuracy for High-Speed Designs

High-speed PCBs often require precise control over signal integrity parameters, such as impedance matching for signals operating at 10 Gbps. IPC-2581 allows designers to embed these specifications directly into the file, ensuring that manufacturers understand the requirements without needing separate documentation.

3. Improved Collaboration Between Design and Manufacturing

IPC-2581 supports bidirectional data exchange, meaning manufacturers can provide feedback on potential issues, such as unmanufacturable trace widths (e.g., below 0.15 mm). This collaborative approach reduces iterations and speeds up the time to market.

Benefits of Replacing Gerber with IPC-2581

Switching to IPC-2581 offers several tangible advantages, especially for those working on intricate projects. Here are some key benefits of adopting this advanced PCB data format.

- Time Savings: By eliminating the need to manage multiple files, IPC-2581 reduces preparation time for data handoff. Designers can export a single file in minutes, compared to the hours sometimes spent organizing Gerber sets.

- Reduced Errors: The consolidated format and embedded metadata minimize miscommunication, ensuring that critical details like via sizes (e.g., 0.2 mm for microvias) are accurately conveyed.

- Cost Efficiency: Fewer errors and faster turnaround times translate to lower production costs, especially for high-volume runs or prototypes with tight deadlines.

- Future-Proofing: As PCB designs continue to evolve with technologies like 5G (operating at frequencies up to 28 GHz), IPC-2581 provides a scalable format that can handle increasing complexity.

Challenges in Adopting IPC-2581

While the benefits are clear, transitioning to IPC-2581 isn’t without hurdles. Some manufacturers may still rely on legacy systems that only accept Gerber files, requiring designers to maintain dual outputs during the transition. Additionally, there can be a learning curve for teams unfamiliar with the XML-based structure of IPC-2581.

However, these challenges are temporary. As more industry players adopt this standard, compatibility issues will diminish. Many PCB design tools already support IPC-2581 export, and educational resources are widely available to help teams get up to speed.

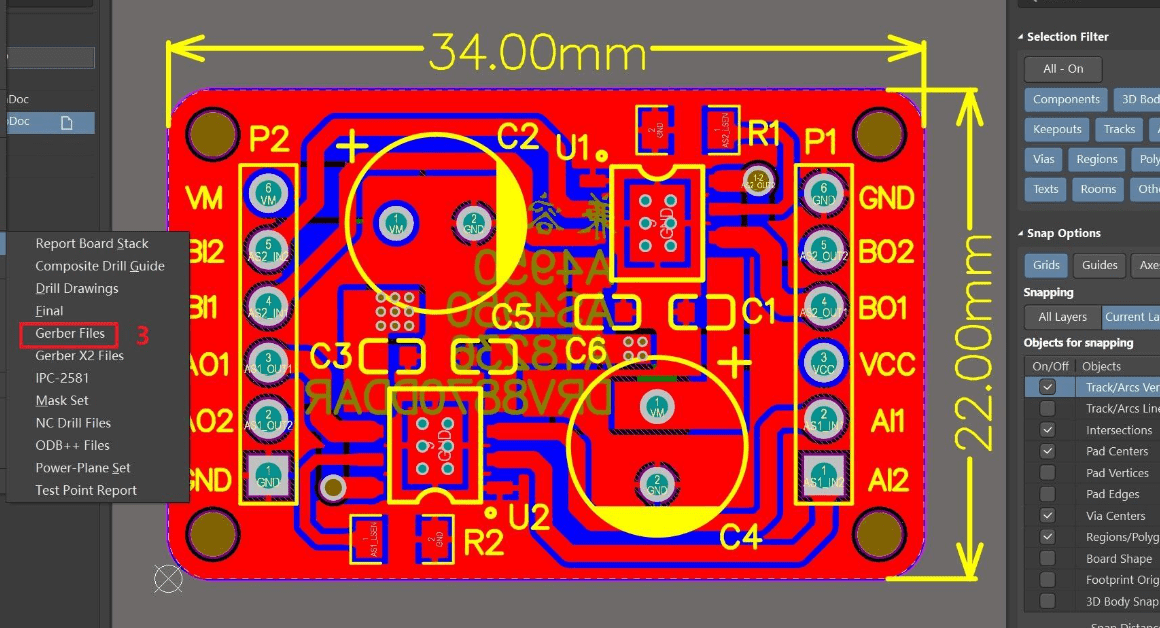

How to Start Using IPC-2581 for Your PCB Projects

If you’re ready to explore replacing Gerber with IPC-2581, follow these steps to integrate this format into your workflow.

- Check Software Compatibility: Ensure your PCB design software supports IPC-2581 export. Most modern tools include this feature as a built-in option.

- Communicate with Your Manufacturer: Confirm that your manufacturing partner accepts IPC-2581 files. If not, discuss a timeline for adoption or provide both formats during the transition.

- Validate Your Data: Use validation tools to check the integrity of your IPC-2581 file before submission, ensuring all layers and metadata are correctly included.

- Leverage Metadata Features: Take advantage of IPC-2581’s ability to embed design intent, such as specifying trace impedance (e.g., 90 ohms for differential pairs) or material requirements.

Real-World Applications of IPC-2581 in Complex Designs

IPC-2581 is already making waves in industries where precision and complexity are paramount. For example, in aerospace applications, PCBs often require strict signal integrity for radar systems operating at frequencies above 10 GHz. IPC-2581 ensures that all parameters, from trace widths to dielectric constants, are communicated accurately in a single file.

Similarly, in the automotive sector, where PCBs must support high-speed data transfer for advanced driver-assistance systems (ADAS), IPC-2581 helps streamline the production of multi-layer boards with embedded components. The format’s ability to handle detailed assembly data reduces the risk of errors in placement and soldering.

Why IPC-2581 Is the Future of PCB Manufacturing

As PCB designs continue to push the boundaries of complexity, the need for an advanced PCB data format like IPC-2581 becomes undeniable. Its single file PCB transfer capability, combined with rich metadata and error prevention features, positions it as a superior choice over Gerber for complex PCB design data transfer.

While Gerber will likely remain in use for simpler designs or legacy systems, the industry trend is clear: IPC-2581 is paving the way for more efficient, accurate, and collaborative PCB manufacturing. By adopting this standard now, designers and manufacturers can stay ahead of the curve and ensure their workflows are ready for the challenges of tomorrow.

Conclusion: Embrace the Change with IPC-2581

The shift from Gerber to IPC-2581 represents a significant step forward for the PCB industry. With its streamlined approach to data transfer and ability to handle intricate designs, IPC-2581 addresses the pain points of traditional formats and offers a path to faster, more reliable production. Whether you’re working on high-speed digital circuits or multi-layer HDI boards, making the switch to this advanced PCB data format can save time, reduce errors, and improve collaboration.

At ALLPCB, we’re committed to supporting the latest standards and technologies to help you achieve your design goals. Start exploring IPC-2581 today and experience the benefits of modern complex PCB design data transfer firsthand.

ALLPCB

ALLPCB